Product Overview

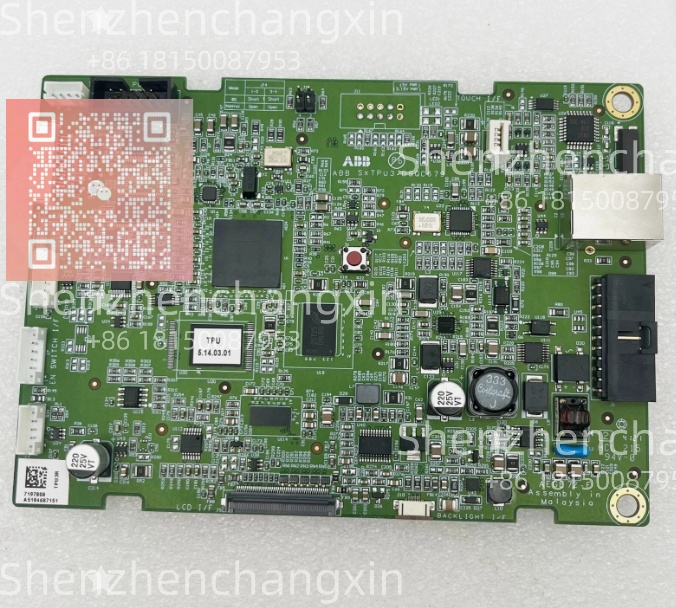

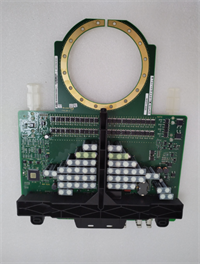

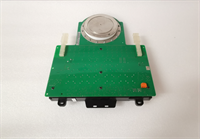

The ABB IRC5 DSQC679 3HAC028357-001 is a critical communication interface module designed specifically for ABB’s IRC5 robot controller,a cornerstone of industrial robotics systems.This module serves as the vital link between the IRC5 controller and various robot peripherals,enabling seamless data exchange that is essential for precise and synchronized robot movements.

As a key component in ABB’s robotics ecosystem,ABB IRC5 DSQC679 3HAC028357-001 facilitates high-speed communication,ensuring that commands from the controller reach the robot joints and end-effectors with minimal latency.This responsiveness is crucial in applications where split-second timing determines the quality of work,such as in automotive welding or electronics assembly.

ABB IRC5 DSQC679 3HAC028357-001 is engineered to handle the rigorous demands of industrial environments,providing consistent performance even amid vibration,temperature fluctuations,and electrical noise.Its integration with the IRC5 platform ensures compatibility with a wide range of ABB robot models,making it a versatile solution for diverse automation needs.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB IRC5 DSQC679 3HAC028357-001

Manufacturer

ABB

Product Type

Robot Controller Communication Module

Compatible Controller

ABB IRC5 Robot Controller

Communication Protocol

ABB proprietary robot bus

Data Transfer Rate

Up to 100 Mbps

Operating Voltage

24V DC

Power Consumption

Max 15W

Operating Temperature

0°C to 45°C

Storage Temperature

-25°C to 70°C

Relative Humidity

5%to 95%(non-condensing)

Dimensions(HxWxD)

120mm×80mm×60mm

Weight

Approximately 0.5kg

Mounting Type

Internal mounting in IRC5 controller

Main Features and Advantages

High-Speed Data Transfer:The ABB IRC5 DSQC679 3HAC028357-001 supports data transfer rates up to 100 Mbps,ensuring that control signals and feedback between the IRC5 controller and robot are transmitted with minimal delay.This is particularly important in high-speed applications like pick-and-place operations,where even a small lag can lead to misalignment or errors in product handling.

Seamless Integration:Designed exclusively for ABB’s IRC5 controller,ABB IRC5 DSQC679 3HAC028357-001 offers plug-and-play functionality,reducing setup time and eliminating compatibility issues.It works harmoniously with ABB’s range of industrial robots,from small collaborative robots to large heavy-payload machines,making it a versatile choice for various automation setups.

Robust Industrial Design:Built to withstand the harsh conditions of factory floors,ABB IRC5 DSQC679 3HAC028357-001 operates reliably in temperatures ranging from 0°C to 45°C and resists the effects of vibration and electromagnetic interference(EMI).This durability ensures uninterrupted operation in environments like automotive factories,where machinery-generated noise is prevalent.

Enhanced Diagnostic Capabilities:The module includes built-in diagnostic features that allow technicians to monitor communication health in real-time.This proactive monitoring helps identify potential issues before they lead to downtime,such as loose connections or signal degradation,making maintenance more efficient and cost-effective.

Application Field

The ABB IRC5 DSQC679 3HAC028357-001 is widely used in automotive manufacturing,where it plays a key role in robot-assisted welding,painting,and assembly lines.In welding applications,for example,it ensures that the robot arm maintains precise movements and timing,resulting in consistent weld quality across vehicle frames.Its high-speed communication is vital here,as even a slight delay can cause weld defects.

In electronics production,ABB IRC5 DSQC679 3HAC028357-001 enables the precise handling of small components by collaborative robots.It facilitates the quick exchange of data between the IRC5 controller and the robot’s grippers,allowing for accurate placement of microchips and circuit board components,where precision down to the millimeter is required.

Food and beverage packaging facilities also benefit from ABB IRC5 DSQC679 3HAC028357-001,as it supports the reliable operation of robots that handle packaging and palletizing tasks.Its robust design ensures that the module continues to function even in the dusty or humid conditions often found in these environments,maintaining consistent production speeds.

Additionally,in logistics and warehousing,the module helps coordinate robot movements in automated storage and retrieval systems,ensuring efficient sorting and handling of goods with minimal errors.

Related Products

ABB DSQC651 3HAC025909-001:A digital input/output module often used alongside ABB IRC5 DSQC679 3HAC028357-001 to expand the IRC5 controller’s I/O capabilities for additional peripherals.

ABB IRC5 Compact Controller:The smaller counterpart to the standard IRC5 controller,fully compatible with ABB IRC5 DSQC679 3HAC028357-001 for space-constrained applications.

ABB DSQC663 3HAC030974-001:A safety controller module that works with ABB IRC5 DSQC679 3HAC028357-001 to enhance robot safety features in collaborative workspaces.

ABB RobotWare Software:The programming software for IRC5 controllers,which communicates with ABB IRC5 DSQC679 3HAC028357-001 to enable custom robot movements and sequences.

ABB DSQC1031 3HAC050991-001:A teach pendant interface module that,when paired with ABB IRC5 DSQC679 3HAC028357-001,allows operators to program and control robots manually.

Installation and Maintenance

Pre-installation preparation:Before installing ABB IRC5 DSQC679 3HAC028357-001,ensure the IRC5 controller is powered off and disconnected from the main power supply to prevent electrical damage.Check that the module’s connectors are clean and free of debris,as dirt can interfere with communication.Refer to the IRC5 controller’s manual to locate the correct internal slot for ABB IRC5 DSQC679 3HAC028357-001–improper placement may cause connection issues or damage to the controller.

Maintenance recommendations:Regularly inspect the connections of ABB IRC5 DSQC679 3HAC028357-001 during routine controller maintenance to ensure they remain secure,as vibration in industrial settings can loosen plugs over time.Keep the area around the module clean and free of dust,which can accumulate and cause overheating.If communication errors occur,use ABB’s RobotStudio software to run diagnostic checks on ABB IRC5 DSQC679 3HAC028357-001–this can often identify issues like signal interference or firmware mismatches.Avoid exposing the module to extreme temperatures beyond its operating range,as this can shorten its lifespan.

Product Guarantee

We guarantee that ABB IRC5 DSQC679 3HAC028357-001 is a genuine ABB product,fully tested to meet the manufacturer’s strict quality and performance standards.All units come with a 12-month warranty covering any defects in materials or workmanship.Our technical support team is available to assist with installation guidance,troubleshooting,and compatibility checks,ensuring that ABB IRC5 DSQC679 3HAC028357-001 integrates smoothly into your robot system.In the unlikely event of a malfunction,we offer prompt replacement or repair services to minimize downtime,reflecting our commitment to providing reliable industrial automation components.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 / 3BHE031197R0001 / 3BHB030310R0001 In stock!!! Interested parties please contact us for negotiation

Reviews

There are no reviews yet.