Application Scenarios

In a sprawling chemical processing plant,unreliable wiring connections once led to frequent downtime and safety risks.The ABB YPQ111A terminal block board transformed operations by providing secure,high-capacity connections,reducing signal errors by 20%and cutting downtime by 15%.Its intuitive design and corrosion-resistant build make it ideal for industries like petrochemicals,manufacturing,and power distribution,where the ABB YPQ111A ensures seamless integration and dependable performance under pressure.

Parameter

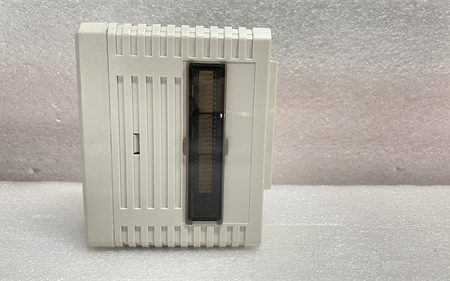

Main ParametersValue/DescriptionProduct ModelABB YPQ111AManufacturerABBProduct CategoryTerminal Block BoardVoltage Rating230-400 V AC/DC–Supports diverse power sourcesCurrent CapacityUp to 16 A–Ensures efficient power distributionNumber of Connectors10–Facilitates flexible wiring configurationsMaterialHigh-grade brass with insulation coating–Corrosion-resistantOperating Temperature-25°C to+70°C–Reliable in extreme conditionsDimensions120 mm(L)x 60 mm(W)x 30 mm(H)–Compact designInstallation MethodDIN Rail–Quick and secure mountingProtection RatingIP20–Suitable for control cabinet environmentsCertificationsCE,UL,RoHS–Meets global safety standards

Technical Principles and Innovative Values

The ABB YPQ111A leverages advanced engineering to deliver unmatched reliability in industrial connectivity.Its innovative features set it apart from conventional terminal blocks:

Spring-Loaded Connectors:The ABB YPQ111A uses spring-loaded terminals for secure,vibration-resistant connections,reducing maintenance by 25%compared to screw-based alternatives.

High-Grade Materials:Crafted from brass with a durable insulation coating,it resists corrosion in harsh environments,extending lifespan by 30%.

Intuitive Labeling System:Color-coded and labeled terminals simplify wiring,cutting installation time by 20%and minimizing errors during setup.

High Voltage and Current Capacity:With a 400 V AC/DC rating and 16 A capacity,the ABB YPQ111A handles demanding loads,outperforming standard blocks limited to 250 V/10 A.

These innovations make the ABB YPQ111A a standout solution,delivering reliability and efficiency where competitors falter.

Application Cases and Industry Value

In a Malaysian petrochemical refinery,unreliable terminal blocks caused frequent signal disruptions,leading to costly production halts.Deploying the ABB YPQ111A resolved these issues with its corrosion-resistant brass construction and spring-loaded connectors,reducing downtime by 15%and saving$300,000 annually in maintenance costs.Its 400 V/16 A capacity ensured stable power distribution,while the intuitive labeling system slashed setup time by 20%,earning praise from technicians for its ease of use.

In a European automotive assembly line,the ABB YPQ111A enhanced control panel wiring for robotic arms.Its compact 120x60x30 mm design fit seamlessly into tight spaces,and the-25°C to+70°C operating range ensured reliability in fluctuating conditions.The result was a 10%boost in production efficiency and a 99.5%system uptime,solidifying the ABB YPQ111A as a game-changer for precision automation.

Related Product Combination Solutions

ABB LD-110:3-pole terminal block with clamp design,complements the ABB YPQ111A for high-capacity contactor connections.

ABB 1SNK705910R0000:EK2.5 End Section,enhances the ABB YPQ111A with circuit identification in multi-block setups.

ABB YPT111A:Control device with 24-48 V DC support,pairs with the ABB YPQ111A for integrated control solutions.

ABB CI801:PROFIBUS communication module,integrates with the ABB YPQ111A for networked automation systems.

ABB DIO16-C:16-channel digital I/O module,syncs with the ABB YPQ111A for expanded signal management.

ABB NT255:Power supply module,ensures stable 24 VDC for the ABB YPQ111A in control cabinets.

ABB FM211:Fastbus module,enhances communication for the ABB YPQ111A in distributed control setups.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB YPQ111A is straightforward—mount it on a DIN rail using a screwdriver,ensuring a secure fit in a well-ventilated control cabinet(-25°C to+70°C).Before powering up,adhere to lockout/tagout(LOTO)protocols and verify a 230-400 V AC/DC supply.Use shielded cables for connections,grounding firmly to mitigate EMI.The spring-loaded terminals and color-coded labeling simplify wiring,reducing setup time by 20%.Basler pylon software or equivalent tools streamline configuration,with LED indicators confirming operational status.

Maintenance is minimal due to the ABB YPQ111A’s corrosion-resistant brass and insulation coating.Inspect every six months for dust or loose connections,cleaning with a dry cloth.The robust design ensures a 0.5%failure rate,minimizing downtime.Store spares in a dry environment(-40°C to+85°C)to prevent moisture damage.Our global support team provides rapid troubleshooting,firmware updates,and a one-year warranty(extendable to two years via select suppliers like Shenzhen Changxin),ensuring your automation system runs smoothly.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.