Application Scenarios

At a combined-cycle power plant in Germany undergoing turbine control modernization, engineers replaced obsolete 4–20 mA cards with the ABB DSAO120 to drive inlet guide vanes and fuel control valves on gas turbines. The DSAO120’s ±0.1% accuracy and 16-bit resolution enabled smoother ramp rates and tighter combustion control, reducing NOx emissions by 12% and improving heat rate efficiency. During a grid frequency event, the module maintained stable output despite severe electrical noise from nearby breaker operations—thanks to its 500 V channel-to-bus isolation and IEC 61000-4-4 Level 4 EFT immunity. Crucially, real-time channel diagnostics in System 800xA alerted operators to a failing positioner on Valve #5 before it caused a trip—demonstrating how the DSAO120 turns passive outputs into intelligent, predictive assets.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Per-Channel Signal Flexibility

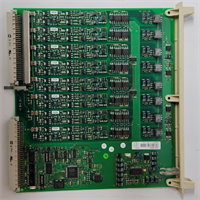

Each of the 8 outputs on the DSAO120 can be independently configured via software for current or voltage mode, eliminating the need for multiple module types and simplifying spares management.

Innovation Point 2: Embedded Diagnostics for Predictive Maintenance

The module continuously monitors output health—detecting open wires, short circuits, or out-of-range conditions—and reports faults directly to System 800xA, enabling proactive maintenance before process disruption.

Innovation Point 3: SIL2 Readiness for Safety Instrumented Functions (SIFs)

When used in accordance with ABB’s safety manuals, the DSAO120 can be deployed in SIL2-rated loops (e.g., emergency fuel cutoff), thanks to its fault detection coverage and hardware architecture compliant with IEC 61508.

Innovation Point 4: Seamless Integration into Unified Engineering

Configuration, calibration, and diagnostics are handled entirely within System 800xA Engineering Studio—no external tools needed. Tag names, scaling, and alarm limits propagate automatically from control logic to HMI.

Application Cases and Industry Value

Oil & Gas Refinery (USA):

The DSAO120 replaced legacy AO cards in a crude distillation unit, driving reflux pump VFDs and reboiler steam valves. Its precise 4–20 mA output reduced temperature oscillations in the fractionator by 40%, increasing product yield. Over one year, energy savings exceeded $220.000.

Water Treatment Plant (Australia):

Used to control chemical dosing pumps via 0–10 V signals, the DSAO120’s stability eliminated overdosing during voltage sags. Integrated diagnostics cut chemical waste by 15% and ensured compliance with environmental discharge limits.

Pulp & Paper Mill (Finland):

In a high-EMI environment near large motors, the DSAO120 maintained accurate dryer cylinder temperature control where previous modules suffered drift. Uptime increased by 95 hours annually due to reduced loop tuning interventions.

Related Product Combination Solutions

ABB AC 800M PM864A/PM866A: Central controller that communicates with DSAO120 via redundant serial buses.

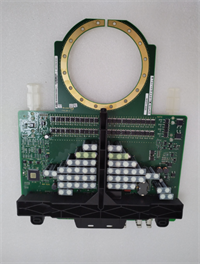

ABB TK811 / TK821 Baseplates: Carrier modules for DIN rail or rack mounting with diagnostic bus support.

ABB TB820 Terminal Blocks: Screw-type or spring-clamp field wiring blocks with test disconnect capability.

ABB DSAI120: Complementary 8-channel analog input module for closed-loop control.

ABB CI854A / CI871AK01: Communication modules (PROFIBUS/PROFINET) for third-party integration.

ABB System 800xA: Full DCS platform for engineering, operation, and asset management.

ABB PCM600: Optional tool for advanced I/O simulation and loop testing during commissioning.

Hitachi Energy Asset Suite: Cloud-based monitoring of I/O module health across enterprise sites.

Installation, Maintenance, and Full-Cycle Support

Installation of the DSAO120 follows standard S800 practices: mount on a compatible baseplate (e.g., TK811), connect shielded twisted-pair cables with shields grounded at the controller end, and configure signal type/scaling in 800xA. The module supports hot-swap in redundant systems, allowing replacement without shutting down the process.

Maintenance is simplified by front-panel LEDs indicating module status and per-channel fault conditions. Calibration is digital and traceable—no potentiometers or manual adjustments required. Firmware and configuration are stored in non-volatile memory, surviving power loss.

We supply every DSAO120 as factory-new, fully tested, with calibration certificates and firmware validated for your specific AC 800M version. All units include a 36-month warranty and are backed by our team of certified ABB/Hitachi Energy automation specialists who provide remote support for loop tuning, SIL2 validation, and migration from legacy systems.

With strategic global inventory, we ensure rapid delivery—even for urgent plant turnarounds or brownfield upgrades.

Contact us for a customized solution—whether you’re building a new greenfield facility, modernizing a legacy DCS, or securing critical spares for decades-old infrastructure, the ABB DSAO120 delivers precision, reliability, and intelligence at the edge of your control system.

Reviews

There are no reviews yet.