.jpg)

Application Scenarios:

In an automotive assembly plant, a new robotic welding cell with all its devices (I/O blocks, valve terminals, photo-eyes) configured for DeviceNet needs to be integrated into the main factory control system, which is based on Profibus DP and controlled by a Siemens PLC. Instead of replacing all devices or the PLC, the system integrator deploys the ANYBUS ABDT-PDP 3183203131. The gateway is configured as a DeviceNet Master, scanning all the welding cell’s devices. On the Profibus DP side, it appears as a standard slave module to the Siemens PLC. The PLC programmer simply defines the input/output data areas for this “slave” in their Profibus configuration. The ABDT-PDP transparently maps the data: sensor statuses from the DeviceNet network are packed and sent to the PLC, and control commands from the PLC are unpacked and sent to the actuators on DeviceNet. This allows the new cell to be fully controlled and monitored by the existing factory automation system without costly hardware changes or complex software development.

Technical Principles and Innovative Values:

The ANYBUS ABDT-PDP 3183203131 is not a simple protocol translator; it is a fully functional, dual-stack device that actively participates on both networks according to their native specifications.

Innovation Point 1: True Dual-Stack Master/Slave Architecture. Unlike simpler bridges, the ABDT-PDP implements complete protocol stacks. On the DeviceNet side, it operates as a full Master (Scanner), actively polling DeviceNet slaves, managing the network, and handling I/O data. On the Profibus DP side, it acts as a standard Slave, responding to cyclic data exchange requests from the Profibus Master. This “citizen on both networks” approach ensures high performance and reliability, as data exchange follows each network’s native timing and rules.

Innovation Point 2: Flexible and User-Friendly Data Mapping. The gateway’s core intelligence lies in its configurable data mapping table. Using the intuitive Anybus Configuration Manager (ACM) software, engineers define exactly how data is transferred between the two networks. For example, 4 bytes of input data from a DeviceNet analog module can be mapped to a specific area in the Profibus slave’s input image. This graphical configuration eliminates complex programming, making integration accessible without deep expertise in both protocols.

Innovation Point 3: Robust Performance and Diagnostics. Designed for 24/7 industrial operation, the ABDT-PDP provides robust performance with configurable watchdog timers and detailed diagnostic capabilities. It monitors the health of both network connections. If one network fails, it can be configured to set default values or hold the last state on the other side, preventing unpredictable machine behavior. Comprehensive status LEDs and web server diagnostics (in newer models) enable quick troubleshooting.

Application Cases and Industry Value:

Case Study: Modernizing a Legacy Packaging Line with New Vision Systems.

A food packaging plant had an older packaging line controlled by a Profibus DP-based PLC. To improve quality control, they needed to integrate new high-speed vision inspection systems. However, the chosen vision cameras and controllers communicated natively over DeviceNet. Rewiring the entire line for a new network was prohibitively expensive and would cause extended downtime. The solution was to use an ANYBUS ABDT-PDP 3183203131 gateway.

The gateway was installed in the main control panel. The vision system’s DeviceNet I/O blocks and controllers were connected to it. On the Profibus side, it was added as a slave to the existing PLC. The integration engineer used the ACM software to map the camera’s “Pass/Fail” signals and inspection data to specific bits and words in the Profibus data table. Within a day, the new vision system was sending real-time quality data to the legacy PLC, which could then trigger reject arms. The plant engineer remarked, “The Anybus ABDT-PDP was the perfect glue. It let us add cutting-edge inspection technology to our 15-year-old control system without a single change to the PLC program’s core logic. We avoided a massive capital project and got the line upgraded over a single weekend.”

Related Product Combination Solutions:

Anybus Configuration Manager (ACM) Software: The essential, free PC-based tool for configuring the data mapping and parameters of the ABDT-PDP and all Anybus Communicator/X-gateway products.

DeviceNet Network Components: Includes DeviceNet trunk cable, drop cables, taps, and terminating resistors (121Ω) required to build the DeviceNet network segment connected to the ABDT-PDP.

Profibus DP Network Components: Includes Profibus cable, connectors, and terminators for connecting the ABDT-PDP to the Profibus DP master.

Anybus AB7602 (or similar): An Ethernet (Modbus TCP) to DeviceNet gateway. Could be used in conjunction with the ABDT-PDP in a more complex network architecture, e.g., to bring DeviceNet data to a SCADA system.

Programmable Logic Controller (PLC) with Profibus DP Master Card: Such as Siemens S7-300/400/1500 with CP 342-5. or Allen-Bradley ControlLogix with a Profibus master module. This is the controller the ABDT-PDP appears as a slave to.

DeviceNet Slaves: The end devices connected to the ABDT-PDP, such as Allen-Bradley Point I/O blocks, motor starters (e.g., SMC Flex), or sensor hubs.

24V DC Power Supply: A stable, well-regulated 24V DC power source is required to power the ABDT-PDP gateway itself.

Installation, Maintenance, and Full-Cycle Support:

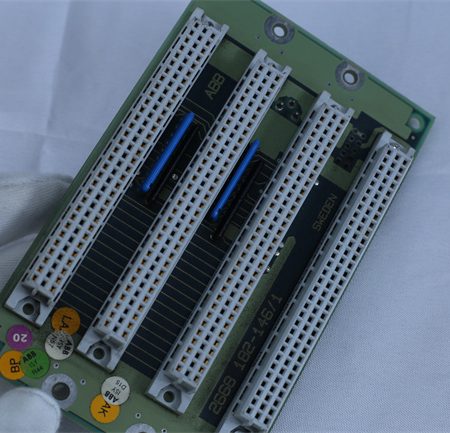

Installation of the ANYBUS ABDT-PDP 3183203131 is straightforward. The compact unit is mounted on a DIN rail. It requires three connections: power (24V DC), the Profibus DP network (via a 9-pin D-sub connector), and the DeviceNet network (via a 5-pin screw terminal or M12 connector). The critical step is the configuration. Using a PC with the Anybus Configuration Manager software connected via Ethernet or serial cable, the engineer defines the DeviceNet network parameters (baud rate, MAC ID) and scans for connected DeviceNet slaves. They then create a mapping between the I/O data of these slaves and the Profibus DP input/output areas assigned by the Profibus master configuration. This configuration file is then downloaded to the gateway.

Once running, the gateway requires minimal maintenance. The status LEDs provide immediate health indication (Power, DeviceNet MS/NS, Profibus OK/Error). For deeper diagnostics, the web server interface (if available) or the ACM software can be used to monitor data exchange and network statistics. Our full-cycle support ensures a successful integration. We provide the hardware, the ACM software, and expert technical support to assist with network planning, configuration mapping, and troubleshooting. We are your partner in solving industrial communication challenges.

Contact us for a customized solution to seamlessly bridge your DeviceNet and Profibus DP systems, extending the life of your assets and simplifying integration.

.jpg)

.jpg)

Reviews

There are no reviews yet.