Product Overview

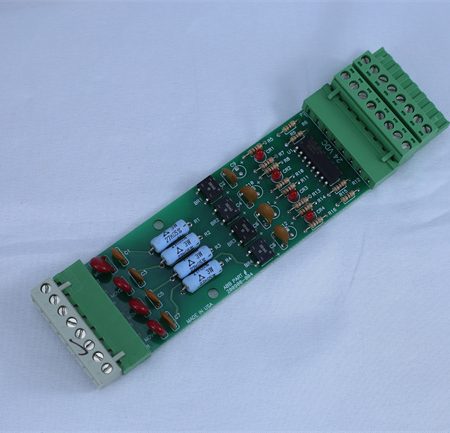

In the protection architecture of modern large rotating machinery, vibration monitoring has long surpassed the scope of mere “warning” and become the legal basis for triggering emergency shutdown (Trip). The BENTLY 128229-01 is the core I/O module in the Bently Nevada 3500 platform designed for this mission – it is not an ordinary signal conditioner, but an engineering-grade solution integrating high-precision acquisition, intrinsically safe isolation, and API 670 compliance. This module is specifically designed for direct connection to eddy current sensors installed in hazardous areas (such as Zone 0/1). Its built-in intrinsic safety (IS) barrier eliminates the drawbacks of traditional external safety barriers, such as signal attenuation, complex wiring, and increased failure points.

I have participated in several SIS upgrade projects for catalytic cracking units and ethylene compressor stations in refineries, and the value of the BENTLY 128229-01 is particularly prominent in these high-risk scenarios. For example, on a propylene compressor operating in an explosive environment, traditional solutions require the installation of multi-channel IS safety barriers between the safe and hazardous areas, which not only occupies extra cabinet space but also introduces additional analog signal paths, reducing overall reliability. With the 128229-01. the sensor cables can be directly connected to the 3500 rack, simplifying wiring and significantly improving MTBF (Mean Time Between Failures) by reducing intermediate components. Its 4-channel design perfectly supports two sets of X-Y orthogonal probe pairs, completely capturing the shaft trajectory and providing full-dimensional data for dynamic balancing and fault diagnosis. Technical Specifications

Product Model: 128229-01

Manufacturer: Bently Nevada (a Baker Hughes company)

Product Type: 4-Channel Intrinsically Safe Dynamic Vibration Input Module (for 3500/42M)

Number of Input Channels: 4 (configured as 2 sets of X-Y orthogonal pairs)

Compatible Sensors: Bently Nevada 3300/3300 XL series eddy current probes

Input Signal Range: -24 V DC to +24 V DC (differential dynamic signal)

Intrinsic Safety Certification: ATEX, IECEx, FM, CSA (for connecting sensors in hazardous areas)

Bandwidth: 0.7 Hz to 10 kHz (-3 dB), meeting API 670 requirements for vibration monitoring

Resolution: 16-bit or higher, effectively supporting micrometer-level displacement measurement

Operating Temperature: 0°C to +65°C

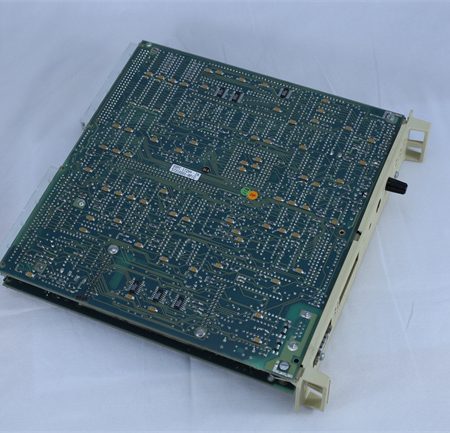

Output Interface: Transmits digitized vibration data to the frame interface module (e.g., 3500/22) via the 3500 backplane

Diagnostic Functions: Sensor open/short circuit detection, probe gap limit alarm, IS barrier status monitoring

Key Features and Benefits

The core advantage of the BENTLY 125800-01 lies in the seamless integration of “safety compliance” and “measurement accuracy.” In environments with flammable gases, such as petrochemical and natural gas facilities, any non-intrinsically safe equipment can become an ignition source. The 128229-01 integrates an IS barrier within the module, ensuring that even in the event of a short circuit or open circuit at the sensor end, the released energy is far below the ignition threshold – a prerequisite for ATEX or IECEx certification. More importantly, this integration does not compromise signal quality: its high input impedance and low-noise front-end circuitry ensure signal fidelity throughout the signal chain from the probe to the controller. 4-channel high-density design saves 50% cabinet space (compared to single-channel modules)

Built-in intrinsic safety barrier eliminates the need for external safety barriers, reducing system complexity and cost

Fully compliant with API 670 5th edition requirements for vibration monitoring system bandwidth, accuracy, and redundancy

Supports X-Y orthogonal mounting for advanced analysis such as shaft orbit and precession direction

Independent diagnostics for each channel provide early warning of probe loosening, cable damage, or abnormal gaps

In practical engineering applications, the 128229-01 is often deployed in a dual role for both machinery protection and condition monitoring. For example, on the drive turbine of an LNG liquefaction plant, its vibration high-high (VHH) output can be directly sent to the Triconex SIS to trigger a trip, while the raw waveform data is uploaded to System 1 for trend analysis. This “one source, two uses” architecture not only meets the independence requirements of functional safety but also avoids redundant investment, reflecting the engineering intelligence of the Bently Nevada system.

The BENTLY 128229-01 is a high-density, intrinsically safe vibration input module engineered for mission-critical machinery protection in hazardous areas. By integrating certified IS barriers directly into the 3500/42M platform, it eliminates external safety barriers while maintaining signal integrity for precise axial vibration measurement. Supporting two orthogonal X-Y probe pairs per module, it delivers full orbit data essential for advanced diagnostics and API 670-compliant trip logic. Its robust design, comprehensive channel-level diagnostics, and seamless integration with System 1 make the 128229-01 the preferred choice for reliable, code-compliant monitoring of compressors, turbines, and pumps in oil & gas, petrochemical, and power generation applications.

Application Areas

The application scenarios of the BENTLY 128229-01 are highly concentrated in industries with explosive environments and extremely high reliability requirements for rotating equipment. It is not only a monitoring tool but also a guarantee of compliance. For example, in the natural gas compressor room of an offshore platform (Class I, Div 1), all electrical equipment must meet intrinsic safety requirements. 128229-01 allows direct connection of 3300 XL probe cables to the 3500 rack in the control room, eliminating the need for additional safety barriers in explosion-proof junction boxes, significantly simplifying design and maintenance.

Oil and Gas: Offshore platform compressors, onshore gathering station booster units, LNG liquefaction refrigerant compressors

Refining and Petrochemical: Catalytic cracking main blowers, ethylene/propylene refrigeration compressors, hydrocracker circulating hydrogen compressors

Chemical: High-pressure synthesis gas compressors for ammonia/urea plants, chlorine turbine compressors

Power: Gas turbine intake/exhaust system fans (if located in hazardous areas)

Legacy system upgrades: Replacing older non-intrinsically safe 3500/40 or 3500/42 modules to improve safety levels

It is particularly noteworthy that the 128229-01 is an ideal hardware platform that meets the latest version of the API 670 standard. This standard explicitly requires vibration protection systems to have sufficient bandwidth and diagnostic coverage, and the 128229-01’s 10 kHz bandwidth and channel-level health monitoring naturally fit this trend, laying a solid foundation for future audits and compliance checks.

Integration and Configuration Highlights

The key to successfully deploying the BENTLY 128229-01 lies in correctly understanding its intrinsic safety characteristics and configuration logic. All parameter settings are completed through the 3500 Configuration Software. Engineers need to define the range (e.g., ±200 µm), alarm/trip thresholds, filtering type (low-pass, band-pass), and whether to enable peak hold for each pair of X-Y channels. A common oversight is neglecting to match the probe’s linear range with the actual installation gap—if the initial gap exceeds the probe’s linear range, even if the module itself is functioning correctly, the vibration readings will be severely distorted.

Field wiring must use Bently Nevada certified three-conductor shielded cables (such as the 330930 series), and ensure that the shield is grounded at a single point on the control cabinet side. Although the module has a built-in IS barrier, the cable length is still limited by the intrinsically safe circuit parameters (usually ≤1000 meters), requiring circuit calculations and verification during the design phase.

Clearly define the engineering units (µm or mils) and direction (Horizontal/Vertical) for each channel in the configuration software.

Enable the “Gap Alarm” function to monitor whether the probe’s static gap drifts out of the safe range.

Use the module’s front panel LEDs for quick status checks: Green = Normal, Red = Channel or IS fault.

Configuration needs to be re-downloaded after replacing the module, but historical trend data is stored in the host system and remains unaffected.

Regularly perform “Loop Test” to verify the integrity of the entire signal chain (probe → cable → module).

These experiences are derived from hundreds of hazardous area projects and can significantly improve system reliability and compliance.

Lifecycle and Procurement Recommendations

The BENTLY 128229-01 is currently in active service and is the standard vibration module for the Bently Nevada 3500 platform in hazardous area applications. Baker Hughes continues to supply and provide full technical support. This means it is not only suitable for new projects but is also the preferred choice for expansion, modification, or spare parts for existing installations. Given its critical role in safety compliance and equipment protection, it is strongly recommended to stock at least one spare module for each type of critical machine.

As a professional service provider of Bently Nevada products, Shenzhen Changxin has established a stable supply channel for brand new, genuine 128229-01 modules. All modules we supply undergo rigorous functional and safety verification: including 4-channel point-by-point signal injection testing, intrinsically safe circuit parameter verification, alarm/trip logic trigger testing, and communication handshake with the 3500/22 frame. All products come with a 12-month warranty and technical consulting is provided by Bently Nevada certified engineers, ensuring that you receive not only compliant hardware but also plug-and-play protection capabilities. Regular models are kept in sufficient stock, supporting emergency orders with delivery within 24-48 hours, providing a solid barrier for your high-risk assets. As a trusted partner in machinery protection, we ensure every BENTLY 128229-01 module meets stringent OEM and functional safety standards. Sourced exclusively through authorized channels, each unit undergoes comprehensive validation—including intrinsic safety barrier verification, multi-channel dynamic signal testing, and full integration checks with 3500 system frames. Our global inventory network guarantees rapid availability, while our team of certified specialists provides expert support from system design to commissioning. When your operations demand reliable, code-compliant vibration monitoring in hazardous environments, rely on us for genuine, tested, and fully supported Bently Nevada solutions.

Reviews

There are no reviews yet.