Application Scenarios

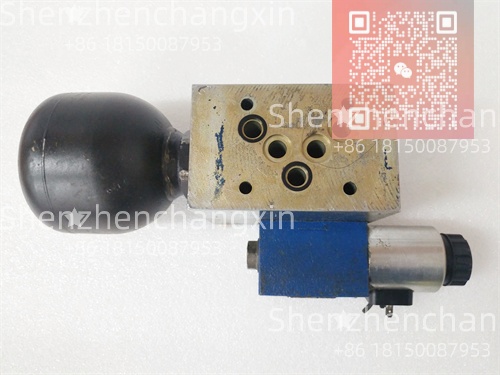

At an automotive stamping plant in Michigan, frequent downtime plagued a 1.200-ton press due to inconsistent ram positioning caused by sluggish hydraulic response from aging valves. Engineers replaced the legacy directional valves with Bosch Rexroth 4WE6Y62-EG24N9K4 units, leveraging their fast switching time (<30 ms) and consistent hysteresis performance. The 4WE6Y62-EG24N9K4’s wet-pin solenoids—rated for continuous duty with low heat generation—eliminated coil burnouts that previously occurred during extended production runs. Additionally, the integrated manual override allowed safe maintenance without system depressurization. Within two months, cycle repeatability improved by 40%, and unplanned valve-related stops dropped to zero. Operators noted the 4WE6Y62-EG24N9K4 “just works—no drift, no lag, no surprises,” underscoring its role as a silent enabler of high-precision hydraulics.

Technical Principles and Innovative Values

Innovation Point 1: Wet-Pin Solenoid Technology – The 4WE6Y62-EG24N9K4 uses solenoids where the plunger operates directly in hydraulic fluid, eliminating air gaps and reducing heat buildup—enabling 100% ED (duty cycle) operation without thermal shutdown.

Innovation Point 2: Precision-Ground Spool & Sleeve – Hard-chromed spool paired with honed sleeve ensures minimal leakage (<0.5 L/min at 350 bar) and smooth metering—critical for position-holding applications like presses or lifts.

Innovation Point 3: Modular CETOP Compatibility – Designed to ISO 4401 standards, the 4WE6Y62-EG24N9K4 replaces competitive valves (e.g., Parker D1VW, Eaton DG4V-3) without manifold modifications—reducing inventory complexity.

Innovation Point 4: Built-In Diagnostics & Safety – Manual override allows safe troubleshooting, while standardized electrical connectors (DIN 43650) support quick plug-and-play replacement—minimizing machine downtime.

Application Cases and Industry Value

A European packaging machinery builder integrated the 4WE6Y62-EG24N9K4 into a high-speed carton erector handling 200 cycles/minute. The valve’s rapid response and consistent flow characteristics ensured precise actuator timing, eliminating misfeeds caused by hydraulic lag. Over 18 months across 120 installed machines, field failure rates were less than 0.3%—far below industry averages. One customer remarked, “We’ve standardized on Rexroth’s 4WE6Y62-EG24N9K4 because it’s the only valve that survives our 24/7 production without service calls.” In another case, a recycling plant used the valve’s corrosion-resistant coating to withstand outdoor exposure near saltwater—proving durability beyond typical industrial expectations.

Related Product Combination Solutions

4WE6E62/EG24N9K4: Alternative spool type (“E” = P→T blocked, A/B→P/T open)—ideal for regenerative circuits.

RSE 4-6/0.6M: Pressure relief valve often mounted on the same manifold as 4WE6Y62-EG24N9K4 for overpressure protection.

ABZMS-35-1X/: Hydraulic filter module recommended upstream to maintain fluid cleanliness (ISO 4406 ≤ 18/16/13).

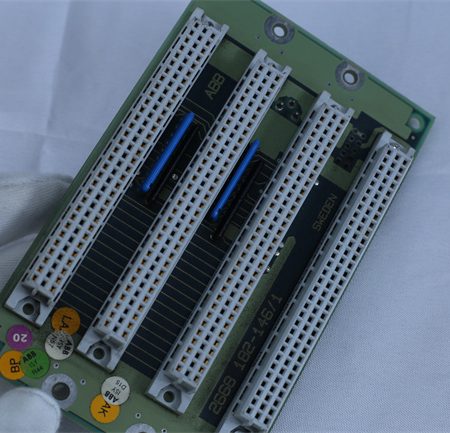

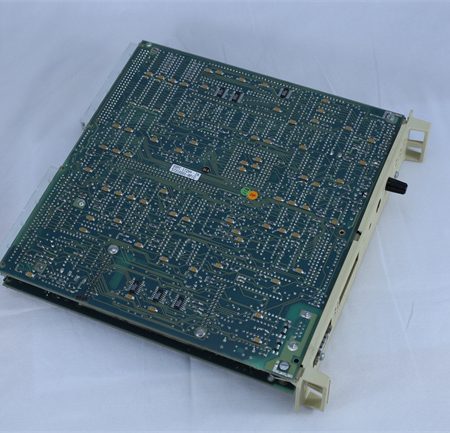

VT-MSPA1-1: Analog amplifier card for proportional control—upgrade path when 4WE6Y62-EG24N9K4 needs variable speed.

CDH1MF / CDH3MP: Compact hydraulic power units pre-configured to drive 4WE6Y62-EG24N9K4-based systems.

4WRPE 6: Proportional directional valve—direct performance upgrade for applications needing closed-loop control.

ZDC 6 P-2X/: Check valve module for load-holding—often combined with 4WE6Y62-EG24N9K4 in vertical cylinder circuits.

HMD 03: Digital pressure switch for monitoring system health alongside 4WE6Y62-EG24N9K4 operation.

Installation, Maintenance, and Full-Cycle Support

Installation of the 4WE6Y62-EG24N9K4 requires mounting on a standard NG6 subplate with O-ring sealing (per ISO 4401). Ensure clean, dry, filtered hydraulic fluid (NAS 9 or better) and torque bolts to 25 Nm in a crisscross pattern to prevent leakage. Electrical connection uses a standard DIN 43650-A plug with strain relief—verify polarity to avoid solenoid damage.

Maintenance is minimal: inspect for external leaks quarterly and verify manual override function annually. Under normal conditions (clean oil, moderate cycling), the valve operates reliably for 10+ million cycles. Should solenoid replacement be needed, the wet-pin design allows field servicing without removing the valve from the manifold. We supply only genuine 4WE6Y62-EG24N9K4 units tested for pressure integrity, flow consistency, and solenoid response time. Each valve includes batch traceability and complies with CE, RoHS, and REACH standards. Backed by a 12-month warranty and global logistics support, we ensure your hydraulic system stays in motion.

Contact us for a customized solution—whether you’re designing new machinery, retrofitting legacy hydraulics, or seeking maximum uptime in demanding environments, the 4WE6Y62-EG24N9K4 delivers proven performance, compatibility, and resilience from the world leader in fluid power.

Reviews

There are no reviews yet.