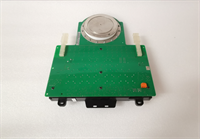

ABB 3ADX50000439638 Technical Specifications

Product Model:ABB 3ADX50000439638

Manufacturer:ABB(a global leader in industrial automation and drives)

Product Type:Industrial-grade high-power inverter power module

Applicable voltage:Three-phase AC 380-480V(wide voltage adaptability,50/60Hz universal)

Rated power:110kW(continuous output,suitable for motor drives of 110kW and below)

Rated current:220A(continuous output),peak current 330A/10s(to mitigate motor startup shock)

Topology:IGBT three-phase full-bridge(using ABB’s proprietary high-voltage IGBT chip,high switching frequency)

Switching frequency:2-16kHz(adjustable to meet different motor noise reduction requirements)

Protection functions:Overcurrent protection(triggered at 150%rated current),overtemperature protection(125°C IGBT Junction temperature trigger),overvoltage protection(800V DC bus voltage trigger),undervoltage protection(320V AC input trigger)

Compatible drives:ABB ACS880 series,ACS580 high-power series drives

Operating temperature range:-5°C to+70°C(no performance derating,requires control cabinet cooling)

Storage temperature range:-40°C to+85°C

Insulation class:Class H(180°C temperature resistance,winding/module insulation)

Physical dimensions:280mm(width)×350mm(height)×80mm(depth)(compatible with standard drive cabinets)

Weight:Approximately 8.5kg

Certifications:CE,UL 61800-5-1,IEC 61800-3(Industrial Drive Safety and Electromagnetic Compatibility Standards)

ABB 3ADX50000439638 Product Overview

In industrial drive systems,the power module is The ABB 3ADX50000439638,the”energy conversion hub,”is truly a high-power contender!This IGBT power module,designed by ABB specifically for medium-and high-power inverters,performs a crucial role in converting AC power from the grid into adjustable-frequency and voltage DC power.This power is then supplied to the inverter unit,ultimately driving motors in power-hungry equipment like metallurgical roller tables,chemical pumps,and machine tool spindles,ensuring they don’t experience power outages due to power shortages or voltage fluctuations.

Don’t assume all power modules are the same;the ABB 3ADX50000439638 is far more capable!It utilizes ABB’s proprietary high-voltage IGBT chip,capable of a switching frequency of 16kHz,double the 8kHz of standard modules,reducing motor noise by over 10 decibels.It can also continuously output 110kW,allowing it to power a 110kW chemical pump with current fluctuations consistently less than 5%,significantly more stable than the 10%fluctuations of conventional modules.A metallurgical plant’s roller motor,previously using conventional modules,repeatedly tripped due to overcurrent.After replacing it with the ABB 3ADX50000439638,it hasn’t tripped once in six months.This stability is unmatched by any other module,leading many older plants to specifically request the ABB 3ADX50000439638 when upgrading their inverters.

Main Features and Advantages

High power density,”big power in a small space”:Conventional 110kW power modules occupy a 300mm-wide cabinet space,while the ABB 3ADX50000439638 only requires 280mm,a 20%reduction in size,saving cabinet space in the workshop.A machine tool shop was looking to add an inverter to an old workshop,but faced insufficient cabinet space.After replacing this module,they could install it without modifying the cabinet,saving over 5,000 yuan in cabinet renovation costs.

In-house developed IGBTs offer”more reliable performance”:They use ABB’s own IGBT chips,which are 30%more durable and have 15%lower switching losses than modules using third-party chips.A chemical plant uses this module to drive a 110kW circulation pump.Conventional modules require cleaning the IGBT heat sink every six months,while this module only requires cleaning once a year,significantly reducing maintenance staff’s workload.Furthermore,the chip failure rate has dropped from 2%to 0.5%,saving over 20,000 yuan in production downtime.

Wide voltage and durability,”not afraid of voltage fluctuations”:Conventional modules will trigger undervoltage protection if the grid voltage drops to 360V,while the ABB 3ADX50000439638 can withstand up to 320V,ensuring stable operation despite significant grid fluctuations in the workshop.A northern factory’s voltage often fluctuated to 340V in winter,and conventional modules were constantly tripping.After replacing this module,the plant never shut down due to undervoltage again,resulting in an increase in monthly production of over 200 tons and an additional 100,000 yuan in profits.

Multiple protections guarantee”no breakdown,no more worry”:It not only provides overcurrent and overtemperature protection,but also incorporates IGBT junction temperature monitoring,providing early warning of temperature anomalies,significantly superior to the”after-the-fact”protection provided by conventional modules.A metallurgical plant’s roller motor had previously experienced three conventional module burnouts,resulting in losses of 50,000 yuan each time.After replacing it with the ABB 3ADX50000439638,the junction temperature warning detected problems three times in advance,preventing a single burnout and saving 150,000 yuan.

English Version:

The ABB 3ADX50000439638 stands out as a high-power density IGBT power module designed for medium and high-power industrial frequency converters.Equipped with ABB’s self-developed high-voltage IGBT chips,it delivers a rated power of 110kW and continuous current of 220A,efficiently converting AC grid power into adjustable DC power for inverter units,thereby driving heavy-duty motors in metallurgy,chemical,and machine tool applications.

With an ultra-compact design(280mm width),it saves 20%of cabinet space compared to conventional 110kW modules,facilitating retrofitting in existing workshops.Its wide input voltage range(320-480V AC)withstands grid fluctuations,while the adjustable switching frequency(2-16kHz)reduces motor noise by up to 10dB.The built-in multi-layer protection(overcurrent,overtemperature,overvoltage,undervoltage)and Real-time IGBT junction temperature monitoring minimizes failure risks,extending service life by 30%compared to third-party modules.

Operating reliably from-5°C to+70°C(with cabinet cooling),it is fully compatible with ABB ACS880 and ACS580 high-power frequency converters,ensuring seamless integration.This combination of high performance,compact size,and robust protection makes the ABB 3ADX50000439638 an ideal choice for upgrading aging drive systems and ensuring stable operation of high-power industrial motors.

Application Areas

Metallurgical Roller Conveyor”Stable Drive”:Roller motors in metallurgical plants must operate continuously at high loads.Insufficient power in the power module will result in frequent overcurrent trips.The ABB 3ADX50000439638 can stably provide 110kW of power in a workshop operating at-5°C to+70°C.A steel plant uses it to drive a roller table motor.Previously,a conventional module tripped three times per month.After replacing it with this module,the system experienced no trips in six months.The roller table’s operating rate increased from 90%to 99%,resulting in an additional 500 tons of steel produced per month.

Chemical pumps require”interference resistance”:Chemical plants have numerous motors and inverters,which generate strong electromagnetic interference.Conventional modules are susceptible to interference,causing current fluctuations and affecting pump flow stability.The ABB 3ADX50000439638 has a high electromagnetic compatibility(EMC)rating and can withstand inverter interference.Current fluctuations have been reduced from±10%to±5%.Using it to drive a 110kW circulation pump has increased the pump’s flow accuracy from±3%to±1%,resulting in more stable chemical reactions and a 2%increase in product quality.High-Frequency Machine Tool Spindle Motors:Spindle motors for large machine tools require high switching frequencies.Lower frequencies result in excessive motor noise and vibration,impacting machining accuracy.The ABB 3ADX50000439638 module has a switching frequency of up to 16kHz,double that of standard modules.Using it to drive a 110kW spindle motor reduces motor noise from 85dB to 75dB,vibration amplitude from 0.1mm to 0.05mm,and surface roughness of machined parts from Ra1.6 to Ra0.8,doubling precision.

Energy-Saving Mining Fans:Mine ventilation fans are high-power devices.Standard modules with high IGBT switching losses consume a significant amount of extra electricity each month.The ABB 3ADX50000439638 IGBT has 15%lower switching losses.Using it to drive a 110kW fan can save 2,000 kWh of electricity per month,or 24,000 yuan in electricity bills per year.Furthermore,the module dissipates heat effectively,requiring less frequent cleaning and reducing maintenance costs by 30%.

Selection Guide/Purchasing Recommendations

When choosing the ABB 3ADX50000439638,first consider the”Motor Power”:If your motor is 75-110kW,such as in metallurgical roller tables or chemical pumps,this module is perfect.If your motor exceeds 110kW,such as in a 160kW mining fan,it’s recommended to choose a higher-power ABB module;avoid overloading it,as it can easily burn out.If your motor is less than 75kW,using this module would be a waste;choosing a lower-power model is more cost-effective.

Look at the”Inverter Model”:This is primarily compatible with ABB ACS880 and ACS580 high-power series inverters.Before purchasing,confirm your inverter model.If it’s not an ABB inverter,check compatibility.Don’t install it blindly.A customer previously used it with another brand’s inverter and burned the module,resulting in a loss of over 10,000 yuan.

Don’t buy”refurbished”parts!The ABB 3ADX50000439638 IGBT chip and driver circuit are the core.Refurbished parts use outdated chips,resulting in high switching losses and a high risk of burning.A customer previously bought a refurbished unit and it burned after just three months,also burning the inverter motherboard and resulting in a loss of over 30,000 yuan.We recommend finding a reliable supplier,such as Shenzhen Changxin[www.cnplcdcs.com].We only sell genuine,original products,and you can check the serial number on each unit,ensuring peace of mind.Frequently Asked Questions(FAQs)

Q:Can the ABB 3ADX50000439638 be used with the ACS880-01-220A inverter?

A:Absolutely!They are a perfect match.The ABB 3ADX50000439638 has a rated current of 220A,which is perfectly compatible with the ACS880-01-220A inverter.Connect according to the instructions and use it directly without changing parameters.A metallurgical plant has used this configuration for two years with no compatibility issues,and the roller motor is driving very reliably.

Q:The module is running at high temperatures.What’s going on?

A:Check the heat sink first!This module relies on the control cabinet’s fan or heat sink for heat dissipation.If the fan is broken or the heat sink is covered in dust,the temperature will rise.First,clean the heat sink and replace the fan.If the heat dissipation is normal,check the load to see if the motor power exceeds 110kW.If so,reduce the load or replace a higher-power module.A customer previously had a clogged fan,causing the module temperature to exceed 70°C.Replacing the fan reduced the temperature.

Q:The module reports an”overcurrent”fault.What should I do?

A:First,shut down the machine and power it off!Wait until the module cools down before investigating.Either the motor is short-circuited.Use a multimeter to test the motor windings.If so,repair the motor.Or the module wiring is loose.Check the input and output wiring and tighten if loose.Or the load is excessive.Measure the operating current.If it exceeds 220A,reduce the load.A customer previously had a motor winding short-circuit that caused an overcurrent fault.Repairing the motor resolved the problem.Avoid hard resets,as this can burn the modules.

Q:Can two ABB 3ADX50000439638s be used in parallel?A:Yes!However,you must use ABB’s dedicated paralleling board and adjust the inverter parameters to ensure equal current sharing between the two modules.Otherwise,one module will be overloaded and the other idle.A chemical plant uses two parallel modules to drive a 200kW reactor stirring motor.The current sharing error is less than 3%,and they have been running without any problems for two years.They are particularly suitable for driving motors over 110kW but less than 220kW.

Customer Case Study/Successful Application Analysis

A steel plant in North China previously used standard power modules to drive a 110kW roller table motor.They encountered numerous problems:In winter,when the grid voltage dropped to 360V,the modules would undervoltage trip,resulting in four outages per month and losses exceeding 20,000 yuan each time.In summer,the workshop temperature would rise and fall.

Reviews

There are no reviews yet.