Main Features and Advantages

The ABB 3BSE004940R1 offers several key features and advantages that underscore its importance in ABB robot systems.Its primary function is seamless human-machine communication.By providing a dedicated and high-integrity link between the robot controller and the teach pendant,the ABB 3BSE004940R1 ensures that operator commands are transmitted instantly and accurately,allowing for precise manual control(jogging)of the robot’s axes during programming and setup.Simultaneously,it enables the real-time display of critical robot data,such as joint positions,program status,I/O states,and alarm messages,on the teach pendant screen,which is vital for efficient troubleshooting and monitoring.A significant advantage is its system integration and reliability.The ABB 3BSE004940R1 is not a generic component;it is engineered specifically for the DSQC 380 architecture and the S4C/S4C+control platform.This deep integration guarantees compatibility and stable operation,minimizing communication errors or latency that could disrupt the programming process or pose a safety risk.The ABB 3BSE004940R1 is built to ABB’s high industrial standards,utilizing robust components and design practices to withstand the electrical noise,temperature variations,and mechanical vibrations found in factory environments.This industrial-grade durability translates into long service life and reduced downtime.Furthermore,the ABB 3BSE004940R1 plays a crucial role in operational safety.A malfunctioning interface board could lead to unresponsive controls or incorrect status information,potentially creating hazardous situations.The proven reliability of the ABB 3BSE004940R1 helps maintain a safe working environment around the robot.

Application Field

The ABB 3BSE004940R1 is deployed exclusively within the ecosystem of ABB industrial robots utilizing the S4C and S4C+controller generations.Its most common application is in automotive manufacturing,where ABB robots equipped with these controllers perform tasks such as spot welding,arc welding,material handling,and machine tending on production lines.In these settings,technicians rely heavily on the teach pendant,and thus the ABB 3BSE004940R1,to program complex welding paths,adjust robot positions,and perform routine maintenance.The ABB 3BSE004940R1 is also found in general industry applications,including plastics handling,die-casting,and palletizing,wherever ABB IRB 2400,4400,or 6400 series robots are employed.The module is essential during the robot commissioning and programming phase,where engineers use the teach pendant to create and fine-tune robot programs.It remains critical for daily operation and maintenance,allowing operators to start/stop programs,jog the robot for part loading/unloading,and diagnose faults.The ABB 3BSE004940R1 is a fundamental component for any facility operating legacy ABB robots,as its failure renders the teach pendant inoperative,effectively halting the ability to program or manually control the robot,making it a high-priority spare part for maintenance teams aiming to minimize unplanned downtime.

Related Products

ABB 3HAB2258-1:A similar DSQC380 series module,potentially a different variant or sub-assembly within the same controller family.

ABB M2002:The main computer unit(MCU)for the S4C controller,which the ABB 3BSE004940R1 interfaces with directly.

ABB DSQC 377:Another signal module in the DSQC 300 series,often used alongside the ABB 3BSE004940R1 for I/O handling.

ABB S4C Controller Cabinet:The complete control system enclosure that houses the ABB 3BSE004940R1,M2002,and other modules.

ABB IRB 2400 Robot:A specific robot model that uses the S4C controller and therefore requires the ABB 3BSE004940R1.

ABB IRB 4400 Robot:Another robot series dependent on the S4C/S4C+platform and the ABB 3BSE004940R1 module.

ABB IRB 6400 Robot:A larger robot model in the same family,utilizing the same controller technology.

ABB Teach Pendant(e.g.,3HAC027785-001):The handheld operator interface device that connects directly to the ABB 3BSE004940R1.

ABB 3BSE003871R1:A power supply module commonly found in S4C cabinets,providing power to the ABB 3BSE004940R1 and other boards.

ABB DSQC 328:An axis computer module responsible for motor control,which receives commands relayed through the system involving the ABB 3BSE004940R1.

Installation and Maintenance

Pre-installation preparation:Prior to installing the ABB 3BSE004940R1,ensure the robot system is completely powered down and locked out to prevent electrical shock and damage to the controller.Wear an anti-static wrist strap to protect the sensitive electronics on the ABB 3BSE004940R1 from electrostatic discharge.Open the S4C controller cabinet and locate the designated slot for the DSQC380 module.Verify that the backplane connectors are clean and undamaged.Have the correct mounting hardware(screws,brackets)and the robot’s electrical schematics or service manual on hand for reference.Carefully remove the ABB 3BSE004940R1 from its anti-static packaging,handling it by the edges only.

Maintenance recommendations:Routine maintenance of the ABB 3BSE004940R1 involves keeping the controller cabinet clean and free of dust,which can cause overheating.Periodically check for any signs of physical damage,burnt components,or bulging capacitors on the ABB 3BSE004940R1.If the teach pendant becomes unresponsive or displays communication errors,the ABB 3BSE004940R1 is a potential culprit.Inspect the connecting cables between the ABB 3BSE004940R1 and the teach pendant for damage or loose connections.Ensure all mounting screws for the ABB 3BSE004940R1 are secure.While the ABB 3BSE004940R1 itself has no user-serviceable parts,verifying its presence and connection is a crucial step in diagnosing teach pendant issues.Avoid exposing the ABB 3BSE004940R1 to moisture or excessive vibration.

Product Guarantee

We provide a comprehensive guarantee for every ABB 3BSE004940R1 module we offer,affirming our commitment to quality and customer satisfaction.Each ABB 3BSE004940R1 is guaranteed to be a genuine ABB product,sourced through reliable channels to ensure authenticity and prevent the risks associated with counterfeit parts.Before delivery,the ABB 3BSE004940R1 undergoes a thorough visual and functional inspection to confirm it is in proper working order,including checks for physical defects and verification of basic connectivity.We back the ABB 3BSE004940R1 with a standard warranty against defects in materials and workmanship.Our support team is available to provide technical guidance for installation and troubleshooting,helping to ensure the ABB 3BSE004940R1 integrates smoothly into your ABB robot system.We understand that the failure of a component like the ABB 3BSE004940R1 can lead to costly production stoppages,and our goal is to supply a reliable,tested replacement that gets your robot back online quickly and safely.

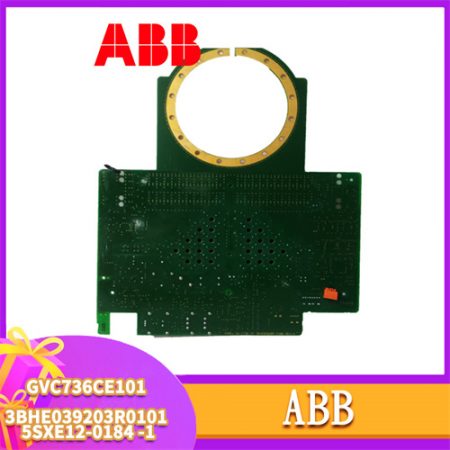

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.