🏭 Application Scenario

At a biopharmaceutical facility in Switzerland, a critical fermentation batch was at risk due to intermittent sensor dropouts caused by an aging third-party power supply. Engineers replaced it with an ABB PU515A (3BSE032401R1) powering a rack of DATX132 digital input bases and AI810 analog modules. The PU515A’s tight output regulation (±1%) and low ripple eliminated signal noise, while its diagnostic relay contact triggered an alarm during a subsequent brownout—allowing operators to switch to backup power before data loss occurred. The batch was saved, and the plant standardized on PU515A for all new GMP-compliant control panels.

💡 Technical Innovations & Value

Innovation 1: Unlike generic PSUs, the PU515A is electrically and mechanically optimized for ABB’s I/O backplane, ensuring minimal voltage drop across long terminal base chains (e.g., TB840A rails).

Innovation 2: Its wide input range (20.4–28.8 VDC) allows seamless integration with battery-backed DC systems common in substations and offshore platforms.

Innovation 3: The integrated diagnostic relay enables predictive maintenance—unlike basic LED-only PSUs—by signaling degradation before total failure.

Innovation 4: When used with the PU515R redundancy module, two PU515A units provide zero-downtime power with automatic load sharing and fault isolation.

🌐 Industry Applications

Power Generation: Supplies clean power to DI/DO modules in turbine control panels

Oil & Gas: Powers intrinsically safe I/O barriers in hazardous areas (with proper segregation)

Water/Wastewater: Drives level switches and pump status sensors in SCADA RTUs

Pharma/Food: Meets hygiene and reliability demands in GMP/GHP environments

Mining: Operates reliably in high-vibration, dusty conditions due to conformal coating options

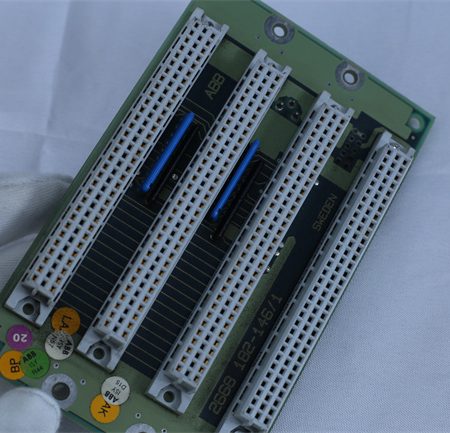

🔗 Related Product Combinations

ABB PU515R (3BSE032410R1): Redundancy module for dual PU515A setups

ABB TB840A / TB850: Terminal bases powered by PU515A

ABB 3BHE024577R0101: 32-ch DI module commonly powered via PU515A

ABB AI810 (3BSE008516R1): Analog input module requiring stable 24VDC

ABB PM866 (3BSE069298R1): AC 800M CPU that monitors PSU health via I/O bus

ABB CI854A: Communication interface linking I/O racks (powered by PU515A) to controller

🔧 Installation & Maintenance

Installation: Snap onto DIN rail adjacent to I/O modules; connect input power and output to I/O bus via standard connectors.

Redundancy Setup: Use two PU515A + one PU515R for N+1 redundancy—no external diodes needed.

Diagnostics: Monitor “PWR OK” LED or wire the relay contact to a supervisory PLC.

Maintenance: No routine servicing required; MTBF > 500.000 hours. Failed units can be hot-swapped in redundant systems.

✅ Support & Warranty

We supply 100% new, factory-sealed ABB PU515A (3BSE032401R1) units with:

Full traceability (batch/date code)

Original firmware and compliance certificates

Pre-shipment functional testing (output stability, overload response, relay function)

24-month warranty and lifetime technical support

📦 Global shipping with ESD-safe packaging. Ideal for system integrators, panel builders, and end-users modernizing legacy ABB installations.

📞 Need a redundant power solution or system compatibility check?

Contact us for engineering support, bulk pricing, or integration guidance for your AC 800M or System 800xA project.

Reviews

There are no reviews yet.