Product Overview

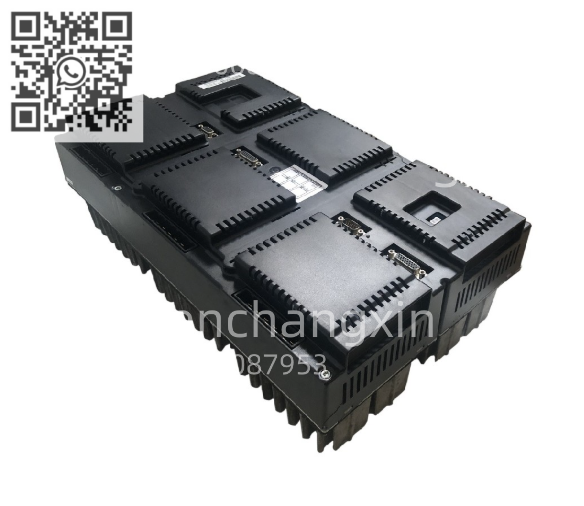

The ABB 3HAC025338-006 is a critical component in advanced industrial automation,specifically identified as a Main Servo Drive Unit.Manufactured by ABB,a global leader in power and automation technologies,this module is integral to the precise control and dynamic movement of industrial robots,particularly within the ABB IRC5 robot controller series.The ABB 3HAC025338-006 serves as the primary power and control interface for a robot’s servo motors,translating control signals from the robot controller into the necessary power commands to drive the individual axes of the robotic arm.This capability ensures high-accuracy positioning,smooth trajectory execution,and powerful torque delivery required for complex manufacturing tasks.

Designed for robust performance in demanding industrial environments,the ABB 3HAC025338-006 plays a pivotal role in maintaining the operational integrity and efficiency of robotic systems.Its function is essential for applications requiring precise and rapid movements,such as welding,material handling,assembly,and painting.By accurately regulating the power supplied to the servo motors,this Main Servo Drive Unit enables the robot to achieve optimal speed,acceleration,and deceleration profiles,which are fundamental to enhancing productivity and ensuring consistent product quality in automated production lines.The reliability and precision of the ABB 3HAC025338-006 underpin the high performance expected from ABB’s renowned robotic solutions.

Technical Specifications

Parameter Name Parameter Value

Product Model 3HAC025338-006

Manufacturer ABB

Product Type Main Servo Drive Unit

Application Industrial Robotics(e.g.,ABB IRC5,IRB 4400)

Drive Type D6 3W 3V(Specific to ABB’s drive nomenclature)

Product Net Weight 11.1 kg

Gross Weight 11.1 kg

Part Type New(when supplied as new)

Customs Tariff Number 85389091/85044095(Varies by classification)

Minimum Order Quantity 1 piece

Replacement Product ID E3HAC025338-(for new versions)

Export to Sheets

Main Features and Advantages

Precision Motion Control:The ABB 3HAC025338-006 is engineered to deliver exceptional precision in motion control,a critical requirement for advanced robotic applications.As a Main Servo Drive Unit,it meticulously converts digital commands from the robot controller into analog or pulse-width modulated(PWM)signals that precisely regulate the speed,position,and torque of the robot’s servo motors.This intricate control ensures that industrial robots,often exemplified by models like the ABB IRB 4400,execute complex tasks with high repeatability and accuracy,crucial for consistent product quality and efficient production cycles.The dynamic response capabilities of the ABB 3HAC025338-006 enable smooth acceleration,deceleration,and path following,minimizing vibrations and overshoots.

Robust and Reliable Design:Built to withstand the rigorous demands of continuous industrial operation,the ABB 3HAC025338-006 features a robust construction that ensures long-term reliability.Its design incorporates advanced power electronics and protective circuitry to safeguard against common industrial hazards such as voltage fluctuations,current surges,and thermal stress.This resilience translates into reduced downtime and lower maintenance costs,maximizing the operational availability of the robotic system.The inherent durability of the ABB 3HAC025338-006 contributes significantly to the overall stability and longevity of ABB’s robotic solutions.

Seamless Integration with IRC5 Controllers:The ABB 3HAC025338-006 is designed for seamless integration with ABB’s IRC5 robot controllers,forming a highly synchronized and efficient control architecture.This compatibility ensures that the drive unit communicates effortlessly with the controller,facilitating rapid data exchange and synchronized motion commands.The integrated design simplifies system setup,configuration,and troubleshooting,allowing for quicker deployment and more efficient operation of robotic cells.The ABB 3HAC025338-006 is a testament to ABB’s commitment to creating cohesive and high-performing robotic ecosystems.

Enhanced Safety Features:Safety is paramount in industrial robotics,and the ABB 3HAC025338-006 incorporates features that contribute to the overall safety of the system.While specific safety functions are managed by the IRC5 controller,the servo drive unit itself is designed to respond reliably to emergency stop signals and adhere to safety protocols,cutting power to the motors rapidly when necessary.This integrated approach to safety helps protect both personnel and equipment in dynamic robotic work cells,aligning with stringent industrial safety standards.

Application Field

The ABB 3HAC025338-006 Main Servo Drive Unit is a cornerstone component for a wide array of industrial applications where precise,reliable,and dynamic robotic motion is essential.Its primary domain is within industrial robotics,particularly in conjunction with ABB’s advanced robotic systems like the IRC5 controllers and IRB series robots.In the automotive industry,the ABB 3HAC025338-006 is critical for driving robots performing complex tasks such as spot welding,arc welding,painting,assembly,and material handling on high-speed production lines.Its ability to provide accurate and responsive motor control ensures consistent weld quality,precise paint application,and rapid assembly cycles,directly impacting vehicle quality and manufacturing efficiency.

In the electronics manufacturing sector,where miniaturization and precision are paramount,the ABB 3HAC025338-006 powers robots engaged in delicate pick-and-place operations,soldering,and intricate component assembly.The drive’s fine control capabilities enable robots to handle small,fragile parts with extreme accuracy,minimizing defects and maximizing throughput in the production of smartphones,circuit boards,and other electronic devices.Furthermore,in metal fabrication and general industry,the ABB 3HAC025338-006 is instrumental in applications like machine tending,grinding,polishing,and deburring,where robots require robust power and precise motion for shaping and finishing various materials.

The versatility of the ABB 3HAC025338-006 also extends to the food and beverage industry for hygienic packaging,palletizing,and processing tasks,as well as in logistics and warehousing for automated sorting and picking systems.Any industry relying on ABB industrial robots for high-performance automation will find the ABB 3HAC025338-006 to be an indispensable part of their drive system,ensuring the robots deliver their full potential in terms of speed,accuracy,and overall operational reliability.

Related Products

E3HAC025338-006:This is identified as the replacement product ID for the ABB 3HAC025338-006,representing the newer version or direct substitute from ABB.

ABB IRC5 Controller:The central control unit that works in conjunction with the ABB 3HAC025338-006 to manage the entire robotic system,providing motion planning and program execution.

ABB IRB 4400 Robot:A specific model of industrial robot from ABB that frequently utilizes the ABB 3HAC025338-006 as its main servo drive unit.

ABB 3HAC025338-001:An alternative or earlier version of a servo drive unit within the same 3HAC025338 series,often compatible or used in similar robotic applications.

ABB 3HAB8101-2:Another related servo drive unit from ABB,typically found in different or older robot series,offering similar functionality but with varying specifications.

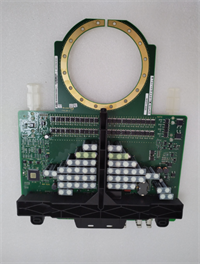

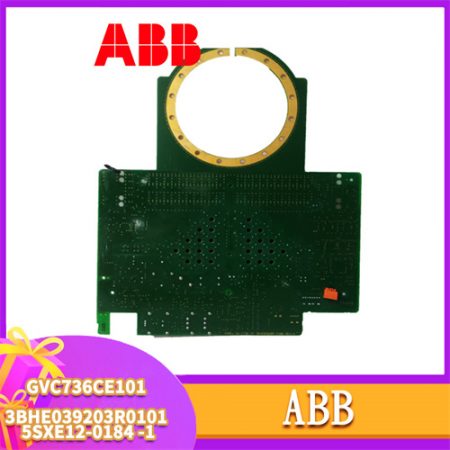

ABB DSQC617:This is likely a specific circuit board or component within the IRC5 controller or a related drive unit,often mentioned in conjunction with the ABB 3HAC025338-006.

ABB Robot Servo Motors:The actual motors that the ABB 3HAC025338-006 powers,converting electrical energy into mechanical motion for each robot axis.

Installation and Maintenance

Pre-installation preparation:Before attempting to install the ABB 3HAC025338-006 Main Servo Drive Unit,it’s paramount to ensure that all power to the robot controller and the associated robotic cell is completely disconnected and locked out according to standard safety procedures.Verify that the mounting location within the IRC5 controller cabinet is clean,dry,and free from any conductive dust or debris,and that ambient temperature and humidity conditions are within the unit’s specified operating range.Inspect the mounting points and electrical connectors for any signs of damage or corrosion,as these can impede proper installation and operation of the ABB 3HAC025338-006.Always refer to the specific installation manual for the ABB IRC5 controller and the ABB 3HAC025338-006 itself,as precise torque values for fasteners and exact wiring diagrams are critical for correct and safe setup.

Maintenance recommendations:To ensure the longevity and optimal performance of the ABB 3HAC025338-006 servo drive unit,regular preventative maintenance is highly recommended.Periodically inspect the unit for any visible signs of wear,discoloration,or loose connections,particularly on the power and motor output terminals.Dust and heat are primary enemies of electronic components,so ensure that the ventilation pathways within the cabinet are unobstructed and clean,allowing for efficient heat dissipation from the ABB 3HAC025338-006.Conduct routine diagnostic checks through the IRC5 controller’s system logs to monitor the drive’s health and proactively identify any impending issues.Any component replacement or advanced troubleshooting for the ABB 3HAC025338-006 should only be performed by qualified and trained personnel,adhering strictly to ABB’s service procedures to maintain system integrity and safety.

Product Guarantee

We are committed to delivering the highest quality industrial automation components,and the ABB 3HAC025338-006 Main Servo Drive Unit is no exception.Our comprehensive product guarantee reflects our unwavering confidence in its performance and reliability.Every ABB 3HAC025338-006 provided is rigorously tested and sourced to ensure it meets stringent quality standards,offering you a dependable solution for your robotic applications.We provide dedicated after-sales service and expert technical support,ensuring that any queries or operational challenges you encounter with your ABB 3HAC025338-006 are addressed promptly and effectively by our seasoned professionals.Our commitment extends to minimizing your downtime and maximizing your operational efficiency,solidifying our promise of excellence and unparalleled customer satisfaction for your investment in the ABB 3HAC025338-006.

ABB 81EU01E-E GJR2391500R1210 GJR2391511R42 Module ABB 07AC91 GJR5252300R0101 Module ABB GJR5252100R3261 ABB 83SR04C-E GJR2390200R1411/GJR2390211R45 Module ABB GJR5250500R3902 / GJR5250500R3902 ABB GJR5-250500-R0202 / GJR5250500R0202 ABB Baugruppe 83SR03K-E GJR2342800R1500 SIE ABB GJR2 316 800 R10 VT 371 D R101 ABB ABB GJR2368900R2200 87TS01I-E BBC 87TS01E 87 TS 01 E ABB ABB GJR2265600r101 VT371Dr101 ABB ProControl vt371 VT ABB/BBC Baugruppe 81ET10C GJR2338700R0001 NOV ABB Baugruppe 83SR03K-E GJR2342800R1500 NOV

Reviews

There are no reviews yet.