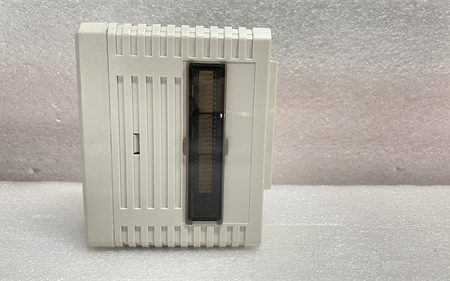

Product Overview

The ABB DSQC611 3HAC13389-2-07A is a critical axis computer module designed for ABB’s S4C robot controller platform,serving as the core motion control processor for individual robot axes.This ABB DSQC611 module is specifically engineered for use with ABB robot models such as the IRB 2400,IRB 4400,and IRB 6400 series,where precise,high-speed servo control is essential for achieving accurate positioning,smooth trajectories,and consistent performance in demanding automation tasks like arc welding,material handling,and assembly.As a key component within the S4C cabinet,the 3HAC13389-2-07A acts as the intermediary between the main robot controller(M2000 CPU)and the servo amplifiers(drive units),translating high-level motion commands into the low-level signals required to drive the robot’s motors.

Functionally,the ABB DSQC611 3HAC13389-2-07A is responsible for executing real-time servo control algorithms,processing feedback from motor encoders and resolvers,and managing the power delivery to the robot’s joints.It ensures that each axis moves in perfect synchronization with the others,maintaining the programmed path and speed with high fidelity.The module handles critical tasks such as position control,velocity control,torque control,and fault monitoring for its assigned axis.Its presence in the control architecture allows for distributed processing,enhancing the overall responsiveness and performance of the robot system.The DSQC611 is built to operate reliably in the electrically noisy and thermally variable environment of an industrial robot cabinet,providing a stable and high-integrity control signal.The 3HAC13389-2-07A is thus fundamental to the robot’s ability to perform complex,dynamic movements with the precision and repeatability required in modern manufacturing.

Technical Specifications

Product Model ABB DSQC611 3HAC13389-2-07A

Manufacturer ABB

Product Type Axis Computer Module

Series/Platform S4C Robot Controller

Function Robot Axis Motion Control

Controlled Axis Typically one primary axis(e.g.,Axis 1,2,or 3)

Interface to CPU DSQC Backplane Bus

Interface to Drive Analog+/-10V Torque Command,Encoder/Resolver Feedback

Power Supply+24 V DC(from Cabinet Power Supply)

Operating Voltage 24 V DC nominal

Signal Types Analog control signals,Digital status signals,Encoder feedback

Processor Dedicated microcontroller for real-time servo control

Memory On-board RAM and ROM for control algorithms and configuration

Operating Temperature 0°C to+45°C(Cabinet Ambient)

Storage Temperature-25°C to+55°C

Humidity 5%to 95%RH,non-condensing

Mounting DIN Rail(within S4C Cabinet)

Approvals CE,UL,cUL

Main Features and Advantages

The ABB DSQC611 3HAC13389-2-07A offers several critical advantages that are essential for high-performance robotic motion control.Its primary feature is dedicated real-time processing,which ensures that servo control loops are executed with minimal latency and maximum consistency.This dedicated processing power is crucial for achieving the smooth motion,high accuracy,and rapid response times required in applications like robotic welding,where even minor deviations can compromise weld quality.By offloading the motion control calculations from the main CPU,the DSQC611 contributes to the overall efficiency and stability of the S4C controller system.

Another significant advantage is its high reliability and robust signal integrity.The 3HAC13389-2-07A is designed with industrial-grade components and shielding to resist electromagnetic interference(EMI)generated by servo drives and other high-power equipment in the cabinet.This ensures that the delicate analog control signals and high-speed digital feedback remain clean and accurate,preventing erratic movements or positioning errors.The module also incorporates comprehensive diagnostic capabilities,often indicated by status LEDs,which allow for quick identification of faults such as communication errors,encoder faults,or over-temperature conditions.This facilitates rapid troubleshooting and minimizes downtime.Furthermore,its standardized design and plug-in architecture make it relatively straightforward to replace in the event of a failure,allowing maintenance personnel to restore robot operation quickly.The ABB DSQC611 3HAC13389-2-07A thus provides the foundation for precise,reliable,and maintainable robot motion control.

Application Field

The ABB DSQC611 3HAC13389-2-07A is a fundamental component in manufacturing environments that rely on ABB’s S4C-controlled robots for precision tasks.Its most prominent application is in automotive manufacturing,particularly in body shops where IRB 2400 and IRB 4400 robots perform high-speed arc welding on car bodies.The module’s ability to deliver precise and consistent motion control is critical for ensuring the quality,strength,and appearance of every weld seam.In powertrain plants,these robots are used for assembling engines and transmissions,where the 3HAC13389-2-07A ensures accurate positioning for tasks like inserting components or applying sealants.

Beyond automotive,the ABB DSQC611 is utilized in general industry for applications such as machine tending,where robots load and unload CNC machines with high repeatability.It is also found in material handling systems for palletizing,depalletizing,and part transfer between production stages.In applications requiring complex path following,such as cutting,sealing,or adhesive dispensing,the real-time control provided by the DSQC611 ensures a smooth and consistent application.The module is particularly vital in environments where production uptime is critical,as a failure in the axis computer can bring an entire production line to a halt.By providing a robust and reliable control link between the robot’s brain and its muscles(the servo drives),the 3HAC13389-2-07A ensures that ABB robots can operate at peak performance,delivering the speed,accuracy,and dependability required for modern,high-volume manufacturing across diverse sectors.

Related Products

ABB DSQC605 is a similar axis computer module used for different axes or robot models within the S4C platform.ABB M2000 CPU(e.g.,3HAC3180-1)is the main controller that communicates with the ABB DSQC611 3HAC13389-2-07A via the backplane.ABB DSQC380 is a digital I/O module that often works alongside the 3HAC13389-2-07A for peripheral control.ABB DSQC652 is a communication interface module(e.g.,for Profibus)that can be integrated into the same S4C cabinet.ABB S4C Cabinet is the complete control enclosure that houses the DSQC611 and other modules.ABB IRB 4400 is a primary robot model that utilizes the 3HAC13389-2-07A for axis control.ABB 3HAC022675-001 is a typical power supply unit for the S4C cabinet,providing power to the ABB DSQC611.ABB 3HAC027865-001 is a common robot cable that connects the signals from the 3HAC13389-2-07A to the servo drives and motors.ABB 3HAC033979-001 is the standard teach pendant used to program and operate the robot system controlled by the DSQC611.ABB DSQC614 is another variant of the axis computer module for specific drive types or configurations.

Installation and Maintenance

Pre-installation preparation:Before installing the ABB DSQC611 3HAC13389-2-07A,ensure the S4C robot controller cabinet is completely powered down and properly locked out to eliminate electrical hazards.Verify that the designated DIN rail slot is clean and the backplane connector is intact and free of dust or damage.Confirm the compatibility of the module with your specific robot model and controller configuration.Gather the necessary tools,including a screwdriver for securing the module and potentially a static wrist strap to prevent electrostatic discharge(ESD)damage to sensitive electronics.Review the system documentation to understand the correct positioning of the 3HAC13389-2-07A within the module sequence on the DIN rail,as its position may correspond to a specific robot axis.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 / 3BHE031197R0001 / 3BHB030310R0001 In stock!!! Interested parties please contact us for negotiation

Reviews

There are no reviews yet.