Application Scenarios

At a European combined-cycle power plant, turbine bearing temperatures were monitored via RTD-to-4–20 mA transmitters feeding legacy I/O with poor resolution, causing delayed overheat alarms. Engineers replaced these with ABB AI02 (3BSE008516R1) modules in the AC 800M racks. The 16-bit resolution and ±0.1% accuracy enabled detection of temperature drifts as small as 0.5°C, allowing predictive maintenance before failures occurred. During a grid frequency event, the AI02’s 500 V galvanic isolation prevented ground-loop interference from distorting vibration sensor readings—ensuring the turbine protection system responded correctly. All channels were configured in Control Builder M within minutes using pre-defined templates, cutting commissioning time by 70%.

Technical Principles and Innovative Values

Innovation Point 1: Universal Input per Channel

Each of the 8 channels can be independently configured (via software) for voltage or current—eliminating the need for external signal conditioners or hardware jumpers.

Innovation Point 2: High Immunity in Electrically Noisy Plants

The 500 V galvanic isolation and differential input design reject common-mode noise from VFDs, switchgear, or welding equipment—critical in steel mills or marine vessels.

Innovation Point 3: Seamless Asset Integration in 800xA

AI02 channel data appears natively in 800xA graphics, trends, and alarms. Open-wire faults trigger “Bad Quality” flags visible to operators instantly.

Innovation Point 4: SIL 2 Compliance for Safety Loops

When used in certified architectures, the AI02 can feed analog values into safety PLCs (e.g., for boiler drum level or reactor pressure monitoring).

Application Cases and Industry Value

In a U.S. municipal wastewater treatment plant, inconsistent DO (dissolved oxygen) readings from aging I/O caused excessive blower energy use. After installing AI02 (3BSE008516R1) modules to read 4–20 mA signals from new optical DO sensors, the SCADA system achieved ±0.05 mg/L accuracy. This enabled precise aeration control, reducing energy consumption by 18% annually (~ $ 94.000 savings). Maintenance staff appreciated the open-circuit detection: when a sensor cable was severed during excavation, the HMI immediately displayed “AI02 Ch5 – Signal Loss,” avoiding false low-DO alarms.

Related Product Combination Solutions

ABB AC 800M CPU (e.g., PM866. SCYC55830): Host controller

ABB AO02: Analog output module (complementary for control loops)

ABB DI01 / DO01: Digital I/O modules for discrete signals

ABB PFEA111: Alternative analog I/O with HART support

Control Builder M: Engineering tool for I/O configuration and diagnostics

ABB 800xA System Platform: For visualization, alarming, and historization

ABB TB840 / TB850: Terminal bases with screw or spring-clamp options

ABB 3BSE008517R1: Spare or updated variant (if available)

Installation, Maintenance, and Full-Cycle Support

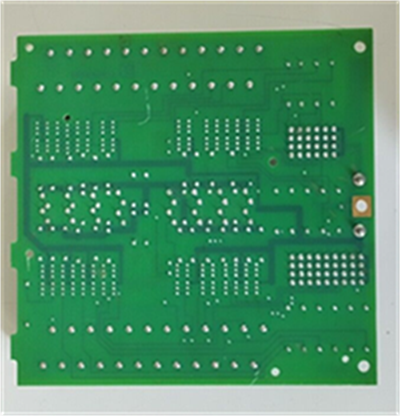

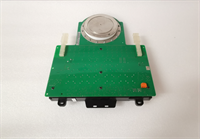

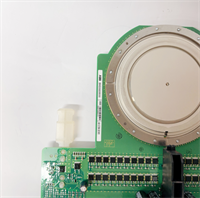

The ABB AI02 (3BSE008516R1) installs directly onto the AC 800M backplane. Field wiring connects via a removable terminal block (TB840/TB850 series). Configuration is done in Control Builder M: assign engineering units, scaling (e.g., 4 mA = 0 bar, 20 mA = 10 bar), and alarm limits.

Key maintenance tips:

Verify sensor loop power if using passive 4–20 mA devices

Check LED status: green = OK, off = no power or fault

Use diagnostic buffer in controller to log signal out-of-range events

We supply only genuine, new-in-box ABB AI02 (3BSE008516R1) modules, each tested for input accuracy, isolation integrity, and communication with AC 800M CPUs. Every unit includes a 12-month warranty and full documentation. Our ABB-certified engineers provide remote support for scaling setup, noise troubleshooting, and SIL integration.

Contact us to upgrade your analog signal reliability—because in process automation, precision starts at the input. The ABB AI02 delivers the fidelity, resilience, and intelligence your control strategy depends on.

Reviews

There are no reviews yet.