Application Scenarios

In a large water treatment plant, the control system needs to communicate with dozens of variable frequency drives (VFDs) controlling pump motors scattered across the facility. Hardwiring each drive’s start/stop and speed signals would be prohibitively expensive and complex. The ABB CI858-1 3BSE018137R1 module provides the elegant solution. Installed in an S800 I/O station, it establishes a high-speed PROFIBUS DP network. Each VFD on the network is configured as a slave device. The CI858-1 acts as the master, continuously polling the drives for status (running, fault, current) and sending setpoints (speed commands). This single communication module replaces miles of control wiring, dramatically reducing installation costs. Furthermore, it enables advanced diagnostics; a drive alarm is not just a simple contact but a detailed message transmitted over the bus, allowing operators to pinpoint issues like overload or overheating immediately. This scenario highlights how the module solves key pain points: reducing capital expenditure (CAPEX) on cabling, lowering installation time, and enabling intelligent device management and diagnostics.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Deep Integration as a Native I/O Controller. Unlike a standalone gateway, the ABB CI858-1 3BSE018137R1 is a fully integrated module within the S800 I/O rack. It plugs directly into the high-speed internal bus of the S800 station, making the connected PROFIBUS slave devices appear as virtual I/O modules within the ABB control system’s configuration tool. This eliminates the need for complex protocol mapping in a separate controller. The AC 800M controller or 800xA system sees the data from a PROFIBUS-connected drive as simply another I/O point, which can be used in control logic with the same simplicity and performance as locally wired I/O, streamlining engineering and program execution.

Innovation Point 2: DP-V1 Protocol Support for Enhanced Diagnostics. The module supports the advanced PROFIBUS DP-V1 standard. While standard DP (Decentralized Periphery) allows efficient cyclic exchange of process data, DP-V1 adds crucial acyclic communication services. This enables the controller to read and write detailed parameter data from intelligent field devices without interrupting the real-time process data flow. In practice, this means an engineer can use the 800xA engineering station to remotely access the detailed parameter set of a connected drive—to check its firmware version, diagnose an alarm log, or modify a configuration parameter—all through the CI858-1. turning it from a simple data pipe into a powerful device management tool.

Innovation Point 3: Robust Network Management and Diagnostics. The CI858-1 is not a passive connector; it actively manages the PROFIBUS network. It handles bus parameterization, monitors slave status, and manages automatic baud rate detection. Its diagnostic capabilities are extensive, reporting not just module-level health but also detailed network and slave-specific errors (e.g., “Slave 5 not responding,” “Short-circuit on segment”). These diagnostics are seamlessly integrated into the 800xA alarm and event system, allowing maintenance personnel to identify and locate network issues quickly, minimizing system-wide downtime caused by a single faulty device on the bus.

Application Cases and Industry Value

Case Study: Automotive Manufacturing Paint Shop Conveyor System. A major automotive plant’s paint shop uses a complex overhead conveyor with hundreds of synchronized drives. The system integrator chose PROFIBUS DP for its deterministic performance and cost-effectiveness. Multiple ABB CI858-1 3BSE018137R1 modules were deployed in S800 stations, each managing a segment of the drive network. The modules provided the precise, cyclic control needed for smooth conveyor movement. During a system upgrade, the DP-V1 functionality of the CI858-1 was critical. Engineers used it to remotely upload the configuration from all existing drives, replicate it onto the new drives, and perform parameter checks—all without touching a single drive keypad, saving weeks of manual work. The project manager stated: “The CI858-1 modules gave us the real-time control we needed for synchronization. Their diagnostic and configuration tools were invaluable for commissioning and cut our changeover time by 40%.”

Case Study: Pharmaceutical Batch Plant with Distributed Motor Control Centers (MCCs). A pharmaceutical facility built a new process area with motor control centers located far from the main control room. Instead of running thousands of wires, they installed remote PROFIBUS nodes in each MCC. An S800 station with a CI858-1 3BSE018137R1 module served as the master for each network, communicating with motor starters, soft starters, and protection devices. The module’s ability to handle the mix of I/O data and intelligent device parameters was key. When a pump motor tripped, the system didn’t just show a “stop” signal; it displayed the exact cause—”Overload Trip, Phase L1. 125% of FLC”—pulled directly from the motor protection device via the CI858-1. This enabled maintenance crews to arrive with the right tools and parts, fixing the issue in minutes instead of hours. The head of engineering noted: “The intelligence delivered by the CI858-1 network transformed our troubleshooting from guesswork to precision, significantly boosting plant availability.”

Related Product Combination Solutions

ABB EI803/ER801/ER802: The S800 Electronic Interface or Remote I/O Base Units. The CI858-1 module must be plugged into one of these base units to receive power and connect to the internal S800 bus and the higher-level controller.

ABB PM864/PM866: The AC 800M Controller Main Units (CPUs). These processors execute the control logic that uses the I/O data provided by the slave devices on the CI858-1’s PROFIBUS network.

ABB CI854: A PROFIBUS DP Slavecommunication module. This module allows an S800 I/O station to act as a slave on a third-party master’s PROFIBUS network, whereas the CI858-1 is a Master.

ABB CI855: An Ethernet/IP Scanner communication module. Used alongside the CI858-1 in the same station for plants utilizing multiple network protocols (e.g., PROFIBUS for drives, Ethernet/IP for other devices).

ABB SD821/SD822: Digital I/O modules. Used in the same S800 station as the CI858-1 for local, hardwired signals, providing a hybrid I/O solution.

ABB PFEA111-20: Analog input modules. Like digital modules, these handle local analog signals, while the CI858-1 handles remote analog devices over the network.

ABB Control Builder Professional: The engineering software where the CI858-1 module is configured, its PROFIBUS network is mapped, and slave devices are defined and integrated into the control application.

ABB COM600/REL670: Protection and substation devices. In power distribution applications, a CI858-1 might be used to integrate protection relays (often with a PROFIBUS DP interface) into the plant DCS for centralized monitoring.

Installation, Maintenance, and Full-Cycle Support

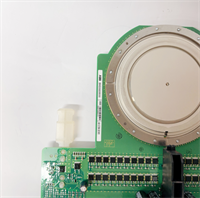

Installation of the ABB CI858-1 3BSE018137R1 is modular and straightforward within the S800 I/O framework. The module is simply plugged into a designated slot in an EI or ER series base unit. The PROFIBUS DP network cable is connected to its front 9-pin D-Sub port. Configuration is performed entirely in software using Control Builder. Here, the engineer adds the CI858-1 module to the station hardware configuration, defines the network parameters (baud rate, profile), and imports the GSD (device master file) for each slave device. The software then provides a user-friendly interface to map the slave’s I/O data to process variables in the controller, making the network integration largely a drag-and-drop exercise.

Routine maintenance focuses on network health monitoring. The module’s comprehensive diagnostics, accessible through the 800xA operator interface or engineering station, provide continuous status on the network, including active slaves, communication errors, and cycle times. The CI858-1 module itself is hot-swappable in a properly configured redundant system, allowing for replacement without a full system shutdown. For network issues, standard PROFIBUS troubleshooting tools like bus monitors or repeaters with diagnostic LEDs are used in conjunction with the module’s own error messages to isolate faults, such as cable breaks or faulty terminators.

We provide comprehensive support for the ABB CI858-1 3BSE018137R1 and your entire industrial network integration. We supply genuine, factory-tested modules and can assist with network design, GSD file management, and configuration best practices. Our technical team can help troubleshoot complex network issues and optimize performance. We understand that reliable communication is the backbone of modern automation, and we are committed to providing the products and expertise to keep your PROFIBUS DP networks running smoothly and efficiently.

Bridge your control system to the field with reliable, intelligent connectivity. Contact us for the ABB CI858-1 3BSE018137R1 and expert PROFIBUS network support.

Reviews

There are no reviews yet.