Application Scenarios:

In a large water treatment facility undergoing modernization, the central control system is being upgraded to an ABB AC 800M platform, but dozens of existing sludge dewatering centrifuges are controlled by legacy PLCs and drives that communicate solely via PROFIBUS DP. Rewiring the entire facility is prohibitively expensive and disruptive. Here, the ABB CMA120 module provides the perfect solution. Installed in the AC 800M controller rack, the CMA120 establishes the controller as the PROFIBUS DP master. It seamlessly polls data from the existing centrifuge drives (speed, torque, alarms) and sends setpoints, effectively integrating the legacy equipment into the new, centralized 800xA operator interface. This allows for advanced supervisory control and data historian collection without replacing functional field assets. The ABB CMA120 solves the key pain point of legacy system integration, protecting prior investments and enabling a cost-effective, phased migration to a modern DCS.

Technical Principles and Innovative Values:

Innovation Point 1: Native Integration as a System Module. Unlike external gateways, the ABB CMA120 is designed as an integral communication module that plugs directly into the AC 800M controller’s rack. This provides a backplane-level, high-speed data connection to the controller’s CPU, ensuring deterministic and low-latency data exchange. This tight integration is more reliable and performs better than a network-connected standalone gateway.

Innovation Point 2: Full PROFIBUS DP-V1 Master Functionality. The module implements the complete DP-V1 standard, supporting not only cyclic data exchange for real-time process values but also acyclic services. This allows for parameterization, configuration, and advanced diagnostics of intelligent slave devices directly from the AC 800M engineering environment, enabling sophisticated device management and condition monitoring.

Innovation Point 3: Transparent Data Mapping and Diagnostics. The CMA120 handles all the low-level PROFIBUS protocol details. Within the Control Builder M software, engineers work with a clean, hardware-independent configuration. I/O data from PROFIBUS slaves is mapped directly to controller process variables. Comprehensive diagnostic information from the network and individual slaves is readily available, simplifying troubleshooting and reducing system maintenance time.

Application Cases and Industry Value:

A major cement plant needed to integrate a new raw mill grinding circuit controlled by an AC 800M with over 50 existing PROFIBUS-connected devices, including weigh feeders, actuator positioners, and motor protection units, spread across a 500-meter area. Using the ABB CMA120 module, engineers configured the AC 800M as the master, creating a single, unified PROFIBUS DP network. The CMA120’s ability to handle the maximum 12 Mbps baud rate and manage a large number of slaves was critical. The integration provided the process engineers with real-time, high-fidelity data from all devices directly on their 800xA screens, enabling advanced process optimization. The plant reported a 20% reduction in commissioning time for the new circuit due to the streamlined configuration tools, and a significant decrease in communication-related troubleshooting, attributing the success to the robust and transparent integration provided by the ABB CMA120 module.

Related Product Combination Solutions:

AC 800M Controllers (PM861. PM864. PM866): The primary controllers that host the CMA120 module, executing the control logic that uses the PROFIBUS I/O data.

S800 I/O with DSPC174: An S800 remote I/O station using a DSPC174 module acts as a PROFIBUS DP slave, allowing the AC 800M (via the CMA120) to control distributed I/O over the same network.

CI854: Another AC 800M communication interface, but for PROFIBUS FMS or other protocols, allowing for multiple fieldbus strategies from a single controller.

ACS800/ACS880 Variable Speed Drives: ABB’s drives that natively support PROFIBUS DP, allowing them to be directly controlled and monitored by the AC 800M via the CMA120.

Control Builder M: The essential engineering software used to configure the hardware layout, set the PROFIBUS master parameters, and map slave device data to the controller application for the CMA120.

PROFIBUS Network Components: Includes cables, connectors, repeaters, and terminators required to build the physical network that the CMA120 manages.

TP830: A test/programming panel for AC 800M, useful for local diagnostics and access when configuring or troubleshooting the system containing the CMA120.

Installation, Maintenance, and Full-Cycle Support:

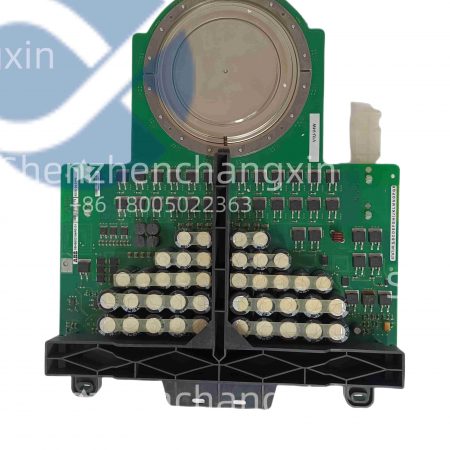

Installation of the ABB CMA120 module involves inserting it into a compatible slot within the AC 800M controller rack, where it is automatically powered via the backplane. The PROFIBUS network cable is then connected to its 9-pin port. The crucial work is done in software using Control Builder M. Here, the engineer adds the CI860 (CMA120) module to the controller’s hardware configuration, sets its PROFIBUS address (usually 1 or 2 for the master), configures the baud rate, and defines the connected slave devices using their GSD (General Station Description) files. Finally, the I/O data from each slave is mapped into the controller’s process image.

Maintenance is primarily software-based and diagnostic. The module’s health is monitored via its status LEDs and the controller diagnostics. Using the engineering station, network diagnostics can reveal issues like slave dropouts, communication errors, or configuration mismatches. The ABB CMA120 itself is a solid-state device with high reliability. Standard network troubleshooting practices apply: checking cable integrity, termination, and slave addresses. We provide genuine ABB CMA120 modules and comprehensive support, from assisting with GSD file management and network configuration to troubleshooting complex communication issues, ensuring your PROFIBUS network operates as a reliable data backbone for your control system.

Streamline your multi-vendor integration with a robust fieldbus master. Contact us for genuine ABB communication interfaces and expert configuration support.

.jpg)

.jpg)

Reviews

There are no reviews yet.