Description

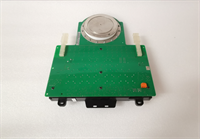

The ABB GVC736BE101 is a specialized gate driver board designed for use in ABB’s ACS1000 medium-voltage AC drives (typically 3.3 kV or 4.16 kV systems). It serves as the critical interface between the drive’s central control unit and the high-power semiconductor switches (such as IGCTs or IGBTs) in the power stack. This board provides isolated gate drive signals, real-time fault detection (including overcurrent, desaturation, and undervoltage), and feedback to the main controller—ensuring safe, efficient, and synchronized operation of the inverter bridge.

While not a standalone product, the GVC736BE101 is an essential service and replacement component for maintaining uptime in industrial applications like pumps, fans, compressors, and conveyors in oil & gas, mining, water treatment, and power generation.

Application Scenarios

At a Middle Eastern desalination plant, an ACS1000 drive controlling a 5 MW high-pressure feed pump tripped repeatedly due to “gate driver fault” alarms. Diagnostics traced the issue to a degraded GVC736BE101 board suffering from capacitor aging and intermittent optocoupler failure. After replacing the board with a new GVC736BE101. the drive resumed stable operation—avoiding a potential 72-hour shutdown that would have cost over $ 500.000 in lost production and penalties. Similarly, in a North American pulp mill, proactive stocking of GVC736BE101 units allowed maintenance teams to execute a 4-hour drive repair during a scheduled outage, rather than waiting weeks for emergency shipping. These cases highlight how this compact board plays an outsized role in system reliability.

Technical Principles and Innovative Values

Innovation Point 1: Fail-Safe Fault Detection Architecture

The GVC736BE101 continuously monitors the collector-emitter voltage of the power device. If a short-circuit or overcurrent occurs, it triggers a desaturation (DESAT) fault within microseconds—shutting down the gate signal before damage propagates. This protects costly semiconductors and prevents cascading failures.

Innovation Point 2: Galvanic Isolation for Safety & Noise Immunity

Using high-isolation optocouplers and isolated DC/DC converters, the board ensures that low-voltage control signals (±15 V logic) remain completely separated from the high-voltage power circuit—meeting IEC 61800-5 safety standards.

Innovation Point 3: Plug-and-Play Integration with ACS1000 Ecosystem

The board auto-identifies its position in the inverter leg (e.g., upper/lower switch) via hardware strapping or firmware mapping, enabling seamless replacement without reconfiguration.

Innovation Point 4: Diagnostic Feedback for Predictive Maintenance

Beyond simple fault signaling, the GVC736BE101 provides analog/digital health indicators (e.g., gate supply voltage levels) that can be logged by the drive’s HMI—supporting condition-based maintenance strategies.

Application Cases and Industry Value

In a Chilean copper mine, a fleet of ACS1000 drives powers slurry pumps 24/7. By implementing a spare parts strategy that includes GVC736BE101 boards, the site reduced mean time to repair (MTTR) from 5 days to under 8 hours. During a recent audit, vibration and heat stress were found to accelerate board aging—prompting the team to add conformal coating during replacements, extending service life by 30%. In Europe, a waste-to-energy plant relies on GVC736BE101-equipped drives for induced draft fans; their reliability ensures compliance with emission control schedules, avoiding regulatory fines. Users consistently note that while small, this board is “the nervous system of the power stack.”

Related Product Combination Solutions

ABB GVC736BE101 + ACS1000 Main Control Board (e.g., VCU736AE101) – Complete drive control chain

ABB GVC736BE101 + 5SHX1445H0001 IGCT Module – Power semiconductor pairing for 3.3 kV systems

ABB GVC736BE101 + Drive Cabinet Cooling Fan Kit – Prevents thermal stress on electronics

ABB GVC736BE102 – Updated or region-specific variant (verify compatibility)

ABB ACS1000 Spare Parts Kit – Includes gate drivers, fuses, sensors, and cables

ABB DriveComposer Pro / PCM600 – Software for drive configuration and diagnostics

ABB GVC751BE101 – Equivalent board for newer ACS5000 or ACS6000 platforms

ABB Gate Driver Test Fixture – For bench validation before installation

Installation, Maintenance, and Full-Cycle Support

Installation of the GVC736BE101 must be performed with ESD precautions (wrist strap, grounded mat). The board slides into a dedicated slot in the power module or backplane and is secured with screws or latches. Always verify correct orientation and connector seating—reversed insertion can destroy the board instantly.

Maintenance best practices include:

Annual visual inspection for bulging capacitors or burnt traces

Cleaning dust with dry air (never solvents)

Verifying gate supply voltages during preventive maintenance

Keeping firmware of the main controller up to date

We test every GVC736BE101 for functionality, isolation integrity, and signal timing using ABB-specified procedures. Units are stored in moisture-barrier bags with desiccant and shipped in anti-static packaging. Backed by a 12-month warranty and supported by engineers familiar with ABB drive architectures, we ensure your replacement minimizes risk and downtime.

Note: As ABB’s drives business is now under Hitachi Energy, long-term support for ACS1000 components like the GVC736BE101 remains active through their global service network.

Contact us for genuine GVC736BE101 boards, technical datasheets, cross-reference support, or assistance with drive troubleshooting—because when your 5 MW process depends on one small board, reliability isn’t optional.

Reviews

There are no reviews yet.