Application Scenarios:

In a steel mill’s hot rolling line, a massive 20-megawatt synchronous motor must be controlled with extreme precision to maintain consistent torque and speed as a red-hot steel slab passes through the rolls. The variable frequency drive powering this motor uses a cascade of high-power switches. Each ABB HIEE300927R0101 (5SHY 35L4520) IGCT within the drive’s inverter section switches thousands of amps at medium voltage levels, synthesizing the precise AC waveform for the motor. Its unique press-pack design allows for direct liquid cooling, enabling it to handle the immense thermal loads. The failure of a single IGCT in this series-connected chain would cause an unplanned production stoppage costing hundreds of thousands per hour. The reliability, switching speed, and ruggedness of the HIEE300927R0101 are therefore fundamental to the mill’s continuous, high-productivity operation, where power density and uptime are paramount.

Technical Principles and Innovative Values:

Innovation Point 1: Superior Switching Performance with Integrated Gate Drive. The IGCT, like the ABB HIEE300927R0101. represents a significant evolution from the GTO thyristor. Its key innovation is the monolithic integration of a high-power thyristor with a low-inductance, anti-parallel gate driver. This integration allows for extremely fast and uniform turn-off across the entire silicon wafer. The device commutates from a thyristor (latching) mode to a transistor (controllable) mode during turn-off, achieving very low switching losses and enabling higher operating frequencies than GTOs, which translates to more efficient, compact drive designs.

Innovation Point 2: Rugged Press-Pack Design for High Reliability. Unlike module-based IGBTs, the 5SHY 35L4520 uses a press-pack housing. The silicon wafer is clamped between two electrodes under high mechanical pressure. This design provides double-sided cooling, drastically reducing thermal resistance and allowing higher current densities. It also fails to a short circuit, which is a safer failure mode in series-connected applications (as used in multi-level inverters) and facilitates easier replacement. This ruggedness makes it ideal for the high mechanical and thermal stress environments of heavy industry.

Innovation Point 3: Enabling Efficient Multi-Level Inverter Topologies. The high-voltage blocking capability and robust switching characteristics of the HIEE300927R0101 IGCT make it the device of choice for advanced Neutral-Point-Clamped (NPC) or other multi-level inverter topologies used in medium-voltage drives. These topologies produce high-quality output waveforms with low harmonic distortion, reducing stress on the motor and eliminating the need for bulky output filters. The IGCT’s capabilities are fundamental to achieving the high power quality and efficiency standards required in modern multi-megawatt drive systems.

Application Cases and Industry Value:

Case Study: Modernization of a Mine Hoist Drive System. A deep-level mine needed to upgrade the drive system for its main production hoist, a critical asset where safety and reliability are non-negotiable. The existing DC drive was inefficient and maintenance-intensive. The upgrade selected was an ABB ACS 6000 medium-voltage drive utilizing IGCT power semiconductors, including the ABB HIEE300927R0101. The drive’s superior control and the IGCT’s robust performance provided smooth, precise torque control throughout the hoist’s acceleration, constant speed, and deceleration cycles. The high efficiency reduced energy consumption by over 20%. Most importantly, the press-pack IGCT design’s proven reliability in high-stress applications provided the mine with the confidence of near-zero unscheduled downtime for the power electronics. Over a five-year period, the hoist’s availability reached 99.9%, directly increasing production capacity and demonstrating the immense value of this core power switching technology.

Related Product Combination Solutions:

The ABB HIEE300927R0101 (5SHY 35L4520) is never used in isolation. It is a key component within a complex power stack:

ABB 5SHY35L4520 / 5SHY3545L0020: The specific IGCT device. (This is the core component referenced by HIEE300927R0101).

ABB 5SXE10-0191 / 5SNA 1200G450300: A related clamping or snubber diode used in conjunction with the IGCT in an NPC cell.

ABB 5STP 12D2800: A Saturable Reactor used to control di/dtduring IGCT switching for improved performance and protection.

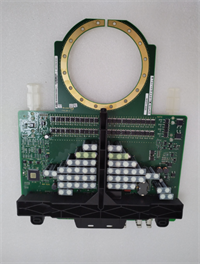

ABB 3BHE039203R0101 GINT561A: A Gate Interface Unit, which is the crucial driver board that provides the precise, high-current gate signals to control the IGCT.

ABB 5SNA 0800G450300: An example of a high-power IGBT module for comparison, representing an alternative technology for different voltage/current ranges.

Liquid Cooling Manifold & Heat Sink: The specific cooling assembly designed to clamp and cool the press-pack IGCT and its associated diode.

ABB ACS 1000/6000 Drive Cabinet: The complete medium-voltage drive system where multiple IGCTs are assembled into power stacks.

Installation, Maintenance, and Full-Cycle Support:

Installation & Commissioning: Installing or replacing an ABB HIEE300927R0101 (5SHY 35L4520) IGCT is a highly specialized procedure. It requires the complete drive to be de-energized, isolated, and grounded. The process involves disassembling the power stack: draining the cooling system, removing the clamping mechanism, extracting the faulty device, and installing the new one with meticulous attention to cleanliness, surface flatness, and the application of the correct contact paste and clamping force (torque). Incorrect installation will lead to immediate failure due to poor thermal contact or mechanical stress. Post-installation, electrical tests and thermal cycling are essential before full-power commissioning.

Maintenance & Fault Handling: The IGCT itself is a non-serviceable component. Preventative maintenance focuses on the health of the cooling system (maintaining water quality, flow, and temperature), monitoring for leaks, and checking the clamping pressure periodically as specified by ABB. A failure is typically detected by the drive’s sensitive protection systems (e.g., short-circuit fault). Diagnosis involves insulation resistance testing and possibly specialized semiconductor testers. Replacement is the only remedy for a failed device.

Full-Cycle Support: We provide critical support for this high-value component. We source genuine or ABB-certified refurbished ABB HIEE300927R0101 / 5SHY 35L4520 IGCTs. Each device undergoes rigorous electrical testing (e.g., high-potential, leakage current) to verify its blocking capability and dynamic characteristics. We understand the critical nature of this component and can often provide or advise on the necessary ancillary items (contact paste, gaskets) and detailed installation procedures. Our support extends beyond the part, aiming to ensure a successful and reliable repair of your critical power conversion system.

Contact us for genuine ABB HIEE300927R0101 (5SHY 35L4520) IGCTs and expert technical support for your medium-voltage drive maintenance and repair.

Reviews

There are no reviews yet.