Application Scenarios

At an automotive component plant in Germany, a legacy Modbus RTU-based assembly line suffered from communication bottlenecks and limited diagnostics. Engineers upgraded to AC 500-S CPU units equipped with LWN2660-6EG modules to connect over 40 VFDs, barcode scanners, and robotic arms via a single EtherNet/IP network. The module’s dual-port embedded switch eliminated external switches, reducing cabinet space by 30%. Real-time I/O updates at 2 ms intervals enabled synchronized motion control between stations, while explicit messaging allowed the MES system to pull production counts and fault logs directly from the PLC—cutting downtime by 22% in the first quarter.

Technical Principles and Innovative Values

Innovation Point 1: Embedded Dual-Port Switch for Simplified Wiring

Eliminates the need for external Ethernet switches—devices can be daisy-chained directly through the LWN2660-6EG, reducing cost, points of failure, and panel footprint.

Innovation Point 2: True Real-Time Performance with Low RPI

Supports 2 ms cyclic I/O updates, enabling tight coordination in high-speed applications like bottling lines or servo-controlled conveyors—rivaling performance of dedicated motion networks.

Innovation Point 3: Unified IT/OT Access via Web Server & Explicit Messaging

Built-in HTTP server allows browser-based diagnostics (IP config, module status, error logs), while explicit messaging enables direct data exchange with SQL databases, ERP systems, or cloud platforms without OPC servers.

Innovation Point 4: Seamless Integration with ABB Ecosystem

Works natively with Automation Builder, Panel Builder 600. and Ability™ Asset Performance Management, allowing drag-and-drop tag sharing between PLC, HMI, and analytics tools.

Application Cases and Industry Value

In a U.S. food packaging facility, 18 LWN2660-6EG modules connected AC 500 PLCs controlling vertical form-fill-seal machines to a central SCADA system over a single EtherNet/IP backbone. The ability to remotely update recipes via explicit messaging reduced changeover time from 25 to 8 minutes per SKU. Additionally, the module’s SNMP trap support alerted maintenance teams to network anomalies before they caused line stops—improving OEE by 14%.

In another case, a Swedish warehouse automation integrator used the LWN2660-6EG to link AC 500 controllers with Rockwell Logix PLCs in a mixed-vendor AGV fleet. Thanks to full ODVA conformance, the ABB PLCs appeared as native EtherNet/IP adapters to the ControlLogix system—enabling unified programming and diagnostics across brands.

Related Product Combination Solutions

PM573-ETH: AC 500 CPU with built-in Ethernet (alternative for simpler applications)

TB511-ETH: Ethernet baseplate for remote I/O expansion

LWN2650-6EG: PROFINET version of the same module family

CPX500: Panel Builder 600 HMI with native EtherNet/IP client support

ABB Ability™ Edgenius: Edge analytics platform for predictive maintenance

TB521: Digital I/O module for high-density discrete control

CI592: PROFIBUS DP master module for hybrid networks

Automation Builder Suite: Engineering software for unified PLC, HMI, and drive configuration

This modular approach supports scalable architectures—from standalone machines to enterprise-wide IIoT deployments.

Installation, Maintenance, and Full-Cycle Support

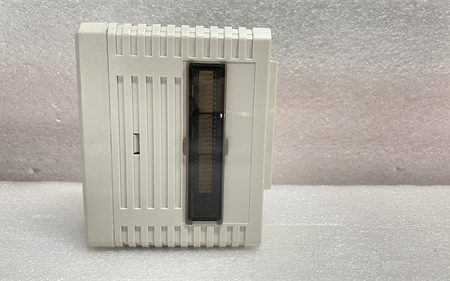

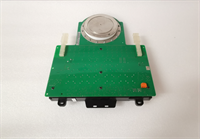

The LWN2660-6EG mounts directly on the AC 500 DIN rail next to the CPU or on remote I/O rails via TB5xx baseplates. Configuration is performed in Automation Builder (v2.5+): assign IP address, define I/O assemblies, and map tags to remote devices. No external power or configuration cables are needed.

Diagnostics include:

Green LED: Link/Activity per port

Red LED: Module fault or IP conflict

Web interface accessible via any browser (default IP: 192.168.1.1)

We rigorously test every 3BHL000986P7002 unit for:

EtherNet/IP conformance (ODVA test suite)

72-hour thermal cycling (0°C ↔ 55°C)

RPI stability under 100% I/O load

Interoperability with Rockwell, Schneider, and Siemens EtherNet/IP devices

All modules are new, factory-sealed, with full traceability and a 12-month warranty. We provide free engineering support for network topology design, GSDML file generation, and migration from Modbus TCP or older fieldbuses.

Contact us for a tailored solution—whether you’re integrating AC 500 into a Rockwell-centric plant, building a smart machine for global OEM distribution, or enabling IIoT connectivity in legacy lines, the ABB LWN2660-6EG (3BHL000986P7002) delivers open, real-time, and future-ready Ethernet communication.

Reviews

There are no reviews yet.