Application Scenarios

In a pharmaceutical batch reactor, precise control of temperature, pressure, and valve sequencing is paramount for product quality and safety. The ABB LXN1604-6 module is deployed as a key interface in this environment. It can be configured to accept analog inputs (e.g., 4-20mA signals from temperature and pressure transmitters) and digital inputs (e.g., status of agitator motors and limit switches) simultaneously. Its high channel density means fewer modules are needed, saving cabinet space. The module’s robust signal conditioning ensures accurate readings even in the electrically noisy environment of a plant floor. This allows the controller to execute complex batch recipes with high fidelity. The LXN1604-6 solves the pain points of signal integrity, cabinet real estate, and configuration flexibility, providing a reliable and consolidated interface for mixed signal types.

Parameter

Technical Principles and Innovative Values

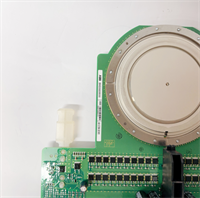

The ABB LXN1604-6 is engineered for flexibility, reliability, and ease of integration within a modern DCS architecture.

Innovation Point 1: Configurable Channel Functionality. A key innovation of this module is its software-configurable channels. Each channel or group of channels can be defined in the engineering software as a digital input, digital output, or analog input (specific types depend on firmware). This eliminates the need to stock different hardware modules for each signal type, reducing spare parts inventory and allowing for last-minute design changes without hardware replacement, offering unparalleled flexibility.

Innovation Point 2: Advanced Diagnostic Capabilities. The module provides comprehensive diagnostics that go beyond simple “good/bad” status. It can detect and report field circuit faults such as wire breaks, short circuits, and signal under-range/over-range conditions. This granular diagnostic information is communicated directly to the control system and operator station, enabling predictive maintenance and drastically reducing mean time to repair (MTTR) by pinpointing the exact nature and location of a field device issue.

Innovation Point 3: Seamless Integration and Hot Swap. The LXN1604-6 is designed for the S800 I/O system, known for its modularity. It plugs into a standard terminal unit (TU) which handles the field wiring. This design allows the electronic module to be hot-swapped—replaced while the system is powered and running—without interrupting the process on other channels. This feature is critical for maintaining high plant availability and allows for maintenance without costly process shutdowns.

Application Cases and Industry Value

Case Study: Water Treatment Plant Distributed I/O Upgrade

A municipal water treatment plant needed to upgrade the control system for its filter backwash process, which relied on aging, unreliable single-point I/O cards. The goals were to improve reliability, reduce maintenance time, and gain better diagnostics. The solution involved deploying an AC 800M controller with distributed S800 I/O racks using ABB LXN1604-6 modules near the filter beds.

Process & Improvement: Each LXN1604-6 was configured with a mix of digital inputs (for valve limit switches and pump run status) and analog inputs (for flow and pressure transmitters). The high density allowed one module to handle all signals for a single filter. When a flow transmitter on Filter 3 developed a fault, the module’s diagnostics immediately flagged a “current below minimum” alarm at the specific channel in the control room, rather than a generic “process variable bad” alert. Maintenance was dispatched directly to the correct instrument, confirming a faulty transmitter. This precise diagnosis referred troubleshooting time by over 70% for that failure mode. The plant reported improved process control stability and a significant reduction in unscheduled downtime due to faster fault resolution.

Related Product Combination Solutions

The ABB LXN1604-6 operates within the cohesive S800 I/O and 800xA system ecosystem.

ABB AC 800M Controller (e.g., PM861. PM863): The central processing unit that executes control logic using the I/O data provided by the LXN1604-6 and sends output commands.

ABB S800 I/O Terminal Unit (e.g., TU847. TU848): The wiring interface that provides the physical connection between field cables and the LXN1604-6 electronic module. It is where the module is physically installed.

ABB CI871 / CI854: Communication Interface modules. These connect the S800 I/O rack (containing the LXN1604-6) to the controller’s network (e.g., via PROFIBUS DP or Ethernet).

ABB SD821 / SD822: Safety I/O Modules. For applications requiring safety-rated signals (SIL2/3), these modules would be used in conjunction with standard modules like the LXN1604-6 for non-safety signals.

ABB S800 Power Supply (e.g., PA871): Provides the regulated power to the S800 I/O rack and all its modules, including the LXN1604-6.

ABB 800xA Operator Workplace: The HMI where operators visualize the process data acquired by the LXN1604-6 and interact with the control system.

ABB Control Builder Professional: The engineering software used to configure the LXN1604-6’s channel types, scaling, and diagnostic parameters, and to program the associated controller.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB LXN1604-6 is modular and straightforward. The electronic module is installed by plugging it into its designated slot in an S800 I/O Terminal Unit (TU). All field wiring is connected to the robust terminal blocks on the TU, not directly to the module itself. Configuration is performed entirely in software using ABB’s Control Builder, where engineers define the function of each channel (DI/DO/AI).

Maintenance is highly streamlined. The clear separation between the “smart” electronic module (LXN1604-6) and the “dumb” wiring interface (TU) simplifies troubleshooting. The module’s advanced diagnostics quickly identify issues. If a module fails, the hot-swap capability allows a technician to simply unplug the faulty unit and insert a replacement without powering down the I/O rack or affecting other channels. The new module is automatically recognized and configured by the system. We provide full lifecycle support, from initial system design and module configuration assistance to 24/7 technical support for troubleshooting. We ensure access to genuine ABB spare parts and firmware updates to keep your system running optimally for its entire operational life.

Optimize your process I/O with flexible, high-performance integration. Contact us for the ABB LXN1604-6 module and comprehensive system support.

Reviews

There are no reviews yet.