Application Scenarios

At a hydroelectric dam in Norway, aging control hardware caused delayed response during load-shedding events. The facility upgraded to a redundant ABB PM825 pair in an AC 800M rack, achieving synchronized hot standby with <8 ms failover. During a grid instability incident six months later, the backup CPU took over instantly—preventing turbine overspeed and avoiding a potential mechanical shutdown. The PM825’s integrated web server also allowed remote engineers to monitor CPU load and memory usage during peak runoff season without on-site visits, demonstrating how modern PLC architecture enhances both safety and operational efficiency in critical infrastructure.

Parameter

表格

Technical Principles and Innovative Values

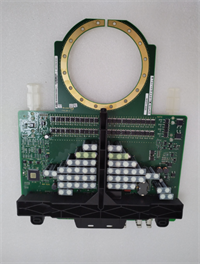

Innovation Point 1: True Synchronous Redundancy – Two PM825 units run in perfect lockstep; if the primary fails, the standby takes over within milliseconds—ensuring zero process interruption.

Innovation Point 2: Integrated Web Server – Access CPU status, I/O health, and task timing via any standard browser—no extra software required.

Innovation Point 3: Cyber-Resilient Design – Supports VLAN tagging, IP filtering, and secure firmware updates aligned with IEC 62443 principles.

Innovation Point 4: Unified Engineering – Fully compatible with ABB Automation Builder and Control Builder M, enabling seamless migration from legacy INFI 90 or MOD 300 systems.

Application Cases and Industry Value

In a Middle Eastern desalination plant, the PM825 replaced a proprietary DCS controller, reducing spare parts inventory by consolidating control onto the AC 800M platform. Its ability to handle 12.000 analog and digital tags across reverse osmosis skids—with scan cycles under 50 ms—improved chemical dosing accuracy by 22%, directly lowering operational costs.

Similarly, in a U.S. district heating network, redundant PM825 controllers managed 30+ pump stations via Modbus TCP over cellular links. The system maintained heat delivery during winter outages, earning the utility a regional reliability award.

Related Product Combination Solutions

ABB PM826: Higher-end CPU with 256 MB RAM and faster processing—backward compatible with PM825 racks.

ABB CI854A: Profibus DP communication module often used alongside PM825 for remote I/O.

ABB 3BSE013208R1: Backup battery module to preserve retentive memory during power loss.

ABB TB850/TB851: Terminal bases for local I/O modules connected via ModuleBus.

ABB AC 800M Rail & Power Supply (e.g., UFC718AE101): Complete rack infrastructure.

ABB HI Module (e.g., PM865-HI): For SIL 3 safety applications requiring separate safety CPU.

ABB Automation Builder Suite: Engineering software for programming and commissioning.

ABB 3BSE041484R1: SD card adapter for program backup and firmware updates.

Installation, Maintenance, and Full-Cycle Support

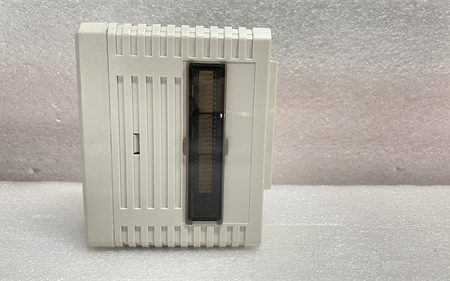

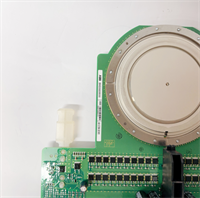

Installation requires mounting the PM825 in an AC 800M chassis (e.g., TK810V001) with proper power and ModuleBus backplane connection. In redundant setups, connect the two CPUs via the dedicated Sync Link port using shielded twisted-pair or fiber cable.

For maintenance, monitor the front-panel LEDs:

Green RUN: Normal operation

Red STOP: Program error or hardware fault

Yellow REDUNDANCY: Sync active (in redundant mode)

Use the built-in web interface (via Ethernet) to check CPU load, memory usage, and I/O communication status. Firmware updates can be performed online via Control Builder M.

We guarantee 100% genuine ABB PM825 (3BSE010796R1) modules—each unit undergoes full functional testing, including redundancy handshake, Ethernet communication, and program execution validation. Every shipment includes original packaging, traceable documentation, and compatibility verification for your existing AC 800M system.

Contact us for expert guidance—whether you’re replacing a failed CPU, expanding your control system, or planning a full migration to ABB’s automation ecosystem.

Reviews

There are no reviews yet.