Application Scenarios

At a coal-fired power plant undergoing digital modernization, legacy hardwired turbine trip circuits were prone to false triggers from electrical noise. Engineers replaced them with a new safety layer using ABB PPD113 (3BHE020455R0101) input modules to monitor vibration switches, lube oil pressure contacts, and bearing temperature alarms—with each channel optically isolated and surge-protected. Simultaneously, ABB PPD103B101 (3BHE023784R2630) output modules drove emergency shutdown solenoids and alarm horns. During commissioning, a simulated bearing overheat triggered a full turbine trip in <80 ms—well within safety requirements. Over two years, zero nuisance trips occurred. In this critical application, the PPD113 and PPD103B101 weren’t just I/O—they were the nervous system of plant safety.

Parameter

表格

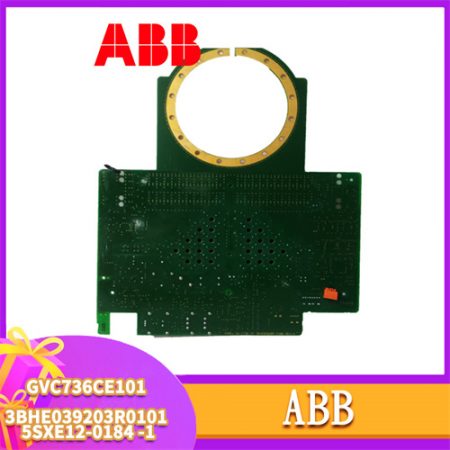

Note: The model PPD103B101 3BHE023784R2630 typically refers to a transistor-output variant (sinking or sourcing, depending on firmware/base). A relay-output version exists under different suffixes (e.g., PPD103R).

Technical Principles and Innovative Values

Innovation Point 1: Intelligent Group Diagnostics Reduce Troubleshooting Time

Both modules report not just signal status but also health data—such as input filter errors or output short circuits—to the controller via the backplane. In ABB 800xA, operators see real-time channel maps with fault highlighting, cutting diagnosis from hours to minutes.

Innovation Point 2: Field-Proven Robustness in Electrically Hostile Environments

With 5 kV surge protection, optical isolation, and conformal coating options, the PPD113 and PPD103B101 operate reliably near VFDs, arc furnaces, and switchyards where commercial I/O fails. Their wide temperature range supports desert and arctic deployments alike.

Innovation Point 3: Seamless Migration Path from Legacy Systems

These modules are pin-compatible with older ABB I/O families (e.g., PCD113/PCD103), enabling brownfield upgrades without rewiring field devices—only the module and terminal base need replacement.

Application Cases and Industry Value

In a North Sea offshore platform, space constraints demanded maximum I/O density with minimum failure risk. A single rack equipped with four PPD113 (3BHE020455R0101) modules monitored 128 fire/gas detector statuses, while three PPD103B101 (3BHE023784R2630) units controlled deluge valves and ventilation dampers. During a real gas leak event, all outputs activated within specification, and the input modules correctly latched the alarm—even amid lightning-induced surges on nearby cables. The platform achieved SIL 2 compliance using these modules in its ESD system. For the operator, this meant not just regulatory approval—but confidence that lives were protected by hardware that never wavered.

Related Product Combination Solutions

ABB TB113 / TB103: Dedicated terminal bases with screw or spring terminals—required for PPD113 and PPD103B101 installation.

ABB PM866: High-performance CPU—manages hundreds of PPD113/PPD103B101 channels across remote racks.

ABB CI854 / O3EN: Communication modules—enable Profibus or Ethernet connectivity for distributed I/O networks using these modules.

ABB TU810 / TU830: Remote I/O adapters—allow PPD113/PPD103B101 deployment up to 200 m from the CPU.

ABB 800xA System 800: Full DCS—provides unified engineering, HMI, and asset management for systems built with PPD113/PPD103B101.

ABB SA811 / PP877K: Power supplies—deliver clean 24 VDC required by these I/O modules at scale.

ABB PPD114 / PPD104: Analog I/O counterparts—complete the signal interface portfolio for mixed-signal applications.

Installation, Maintenance, and Full-Cycle Support

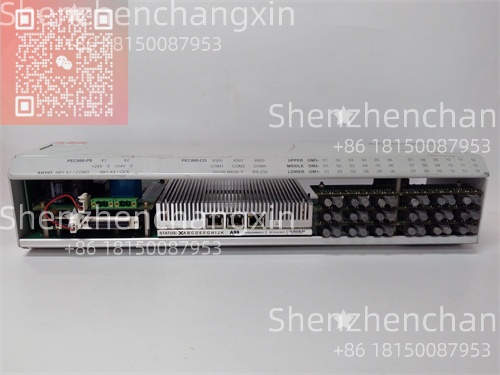

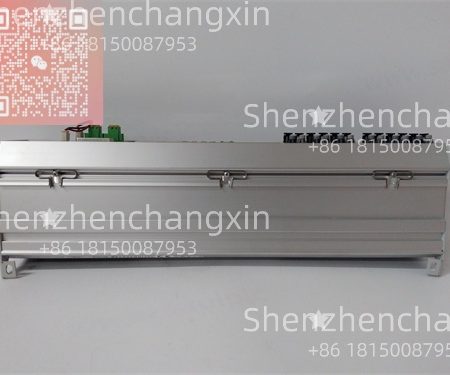

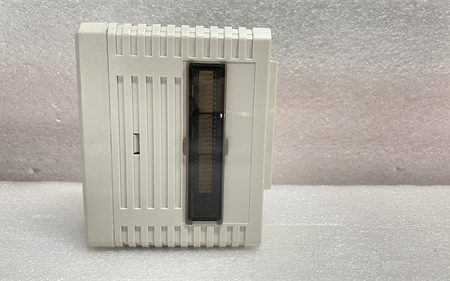

Installation requires mounting the correct terminal base (e.g., TB113 for PPD113) on a DIN rail, then snapping the module into place. Wiring connects to removable terminal blocks for easy maintenance. Both modules support hot-swap—allowing replacement during operation without powering down the rack.

Maintenance involves visual inspection of LEDs and periodic verification of field device continuity. If a short circuit occurs on a PPD103B101 output, only the affected group disables—other channels remain active. All units we supply undergo 100% functional testing: input threshold validation, output load testing, isolation checks, and thermal cycling.

We provide a 12-month warranty, original ABB documentation, and compatibility assurance for both new builds and legacy system retrofits. Our engineers can also assist with I/O allocation planning, redundancy design, and migration from older ABB or third-party platforms.

Contact us for a customized solution—whether you’re modernizing a hydroelectric dam, automating a refinery flare system, or building a modular process skid, the ABB PPD113 (3BHE020455R0101) and PPD103B101 (3BHE023784R2630) deliver the reliability, diagnostics, and ruggedness your industrial processes demand.

Reviews

There are no reviews yet.