Application Scenarios

At a petrochemical complex in Saudi Arabia, operators struggled with glare and touchscreen failures on legacy HMIs installed in outdoor compressor shelters—temperatures regularly exceeded 50°C, and sand infiltration caused frequent system crashes. After upgrading to the ABB PPD113B01-10-150000 3BHE023784R1023. visibility improved dramatically thanks to its 1000 cd/m² high-brightness screen and anti-reflective coating. The fully sealed front panel (IP65) resisted dust and washdowns, while the wide operating temperature range ensured 24/7 uptime. During a critical ethylene compressor surge event, an operator successfully executed an emergency ramp-down using the responsive resistive touchscreen—preventing a $ 5M mechanical failure. Maintenance logs now show zero display-related outages in 18 months, a first in the plant’s history.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Sunlight-Readable Clarity – The PPD113B01-10-150000 3BHE023784R1023 uses a high-luminance LED backlight and anti-glare surface treatment to maintain readability under direct desert sun or bright plant lighting—unlike standard office-grade displays that wash out.

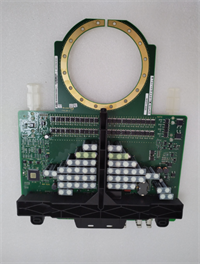

Innovation Point 2: Industrial-Grade Touch Durability – Its 5-wire resistive touchscreen withstands millions of actuations, chemical exposure, and operation with gloves or styluses—ideal for hazardous or sterile environments where capacitive screens fail.

Innovation Point 3: Seamless 800xA Integration – Pre-certified for ABB 800xA Operator Workplace; supports native alarm banners, faceplate navigation, and trend overlays without third-party drivers.

Innovation Point 4: Long-Term Availability & Serviceability – Designed for 10+ year lifecycles; modular construction allows backlight or touchscreen replacement without full unit swap—reducing total cost of ownership.

Application Cases and Industry Value

In a Scandinavian district heating plant, the ABB PPD113B01-10-150000 3BHE023784R1023 replaced aging CRT monitors at boiler control stations. Despite sub-zero winter temperatures and high humidity from steam leaks, the display maintained stable operation through three heating seasons. Operators particularly praised the consistent color accuracy and fast response during load-following mode, where rapid setpoint adjustments are routine. The plant reported a 25% reduction in local HMI maintenance calls and eliminated seasonal “fogging” issues that previously obscured critical pressure readings. The display’s compatibility with existing 800xA graphics saved over 200 engineering hours in reconfiguration.

Related Product Combination Solutions

ABB 800xA Operator Workplace: Primary HMI software fully optimized for PPD113B01-10-150000 3BHE023784R1023 visualization.

ABB CI854 / CI873: Communication modules linking AC 800M controllers to the HMI network feeding the PPD113B01.

ABB PPD113B01-10-190000: 19-inch variant for main control room overview walls—shares same firmware and mounting logic.

ABB TB510: Mounting kit with EMC gasket for secure, shielded installation of PPD113B01 in stainless steel panels.

ABB AC 800M PM864: Controller that drives real-time data to PPD113B01 displays via Ethernet.

ABB Asset Optimization: Software layer that overlays equipment health data onto PPD113B01 process graphics.

ABB PCD221: Compact industrial PC that can drive multiple PPD113B01 units in multi-display kiosks.

Installation, Maintenance, and Full-Cycle Support

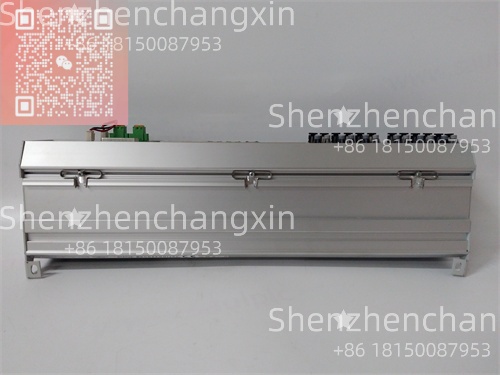

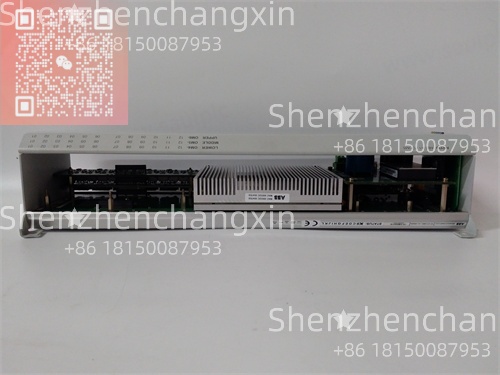

Installing the ABB PPD113B01-10-150000 3BHE023784R1023 requires only a standard cutout in the control panel, connection of 24 V DC power, VGA video, and USB touch cable. Auto-detection in 800xA simplifies resolution and calibration setup. The display’s front-sealed design prevents ingress during washdowns, while its aluminum chassis dissipates heat efficiently—no internal fans to clog with dust.

For maintenance, the resistive touchscreen can be recalibrated via USB utility, and the high-brightness LED backlight has a rated life of 50.000 hours. In case of failure, modular components (touch overlay, LCD panel, power board) can be replaced individually. We provide full lifecycle support—including obsolescence notices, cross-reference guides for migration to newer PPD2xx series, and on-site commissioning assistance. Every PPD113B01-10-150000 3BHE023784R1023 undergoes 72-hour burn-in testing and ships with a 24-month warranty.

Contact us for a customized solution—whether you’re modernizing local operator stations, deploying new skid-mounted control panels, or ensuring HMI reliability in extreme industrial environments.

Reviews

There are no reviews yet.