Application Scenarios

Imagine a large chemical plant that produces ethylene,where a sudden overpressure in the reaction vessel could lead to catastrophic accidents.Previously,the plant used a basic safety relay system to monitor vessel pressure,but the system had a response delay of 200ms—too slow to prevent pressure spikes from reaching dangerous levels.This resulted in two minor incidents in a year,each causing 8 hours of downtime and$50,000 in losses.After upgrading to the ABB SECG-01 3AAA0000051449,the plant achieved a response time of 50ms.

The ABB SECG-01 3AAA0000051449 continuously monitored the pressure sensor signals and,when a pressure spike was detected,triggered the emergency valve shutdown within 50ms—stopping the pressure rise before it exceeded the safe threshold.Additionally,its redundant design ensured the module remained operational even when one of its internal circuits failed,eliminating unplanned safety system outages.Over the next year,the plant recorded zero safety incidents related to pressure overshoots,reducing downtime losses to zero and significantly improving on-site safety.This scenario underscores the product’s critical role in mitigating risks in high-hazard industrial settings.

Parameter

Main Parameters

Value/Description

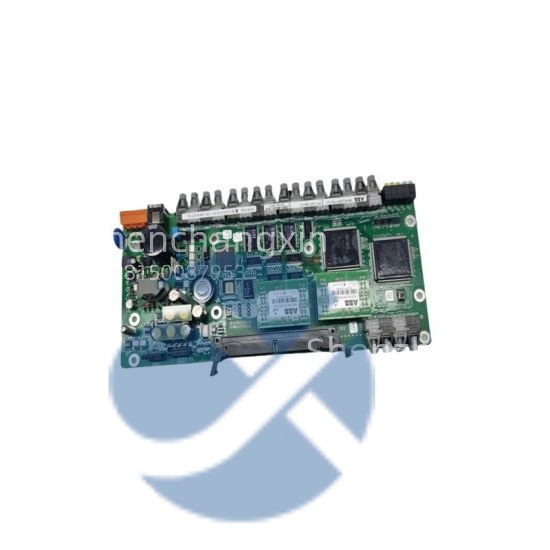

Product Model

ABB SECG-01 3AAA0000051449

Manufacturer

ABB(Swiss-based global leader in industrial automation&safety)

Product Category

Industrial safety control module(for safety monitoring&emergency response)

Safety Certification

SIL 2(per IEC 61508)–meets global safety requirements for high-risk applications

Response Time

≤50ms–ensures fast emergency action to prevent hazardous events

Input Channels

8x analog input(4-20mA,for sensors like pressure,temperature)+4x digital input(for safety switches)

Output Channels

4x digital output(for triggering shutdowns,alarms,or valve controls)

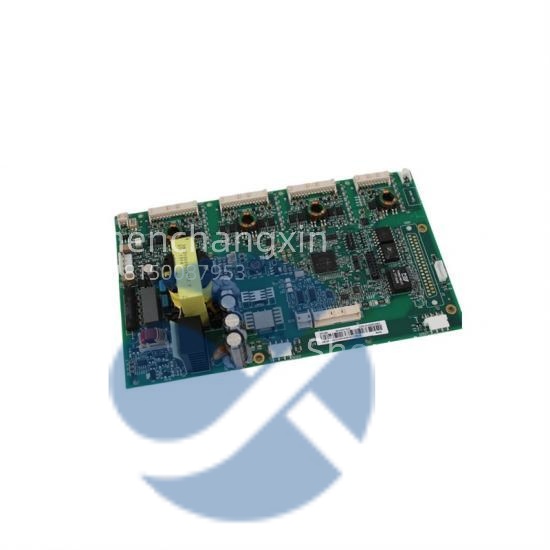

Redundancy

2-channel redundant power supply&signal processing–prevents single-point failures

Operating Voltage

24V DC(±10%tolerance)–compatible with standard industrial power systems,powered by ABB SDCS-POW-4

Operating Temperature Range

-20°C to 60°C–withstands extreme temperatures in outdoor or high-heat industrial areas

Installation Method

DIN rail mount–easy integration into standard control cabinets,saves installation time

Dimensions(W×H×D)

90mm×140mm×60mm–compact design optimizes cabinet space

Weight

~450g–lightweight for easy DIN rail mounting

Communication Interface

RS485(supports Modbus RTU safety protocol)–enables data transmission to safety PLCs

Compliance Standards

IEC 61508(SIL 2),IEC 61511(process safety),EN 60204-1(electrical safety)–meets global industry standards

Fault Detection

Built-in self-diagnostic function(detects internal circuit faults,sensor disconnections)–ensures module reliability

Power Consumption

≤5W–low energy use,reduces heat generation in control cabinets

Warranty Period

3 years(extendable to 6 years)–long-term guarantee for safety-critical applications

Technical Principles and Innovative Values

Innovation Point 1:SIL 2-Certified Safety Architecture

Unlike basic safety relays that lack formal safety certification,the ABB SECG-01 3AAA0000051449 features a SIL 2-certified architecture per IEC 61508.It uses a”2-out-of-2″(2oo2)voting logic for critical signal processing—meaning two independent circuits must confirm a hazard before triggering a response.This reduces the probability of false alarms(by 90%compared to single-circuit systems)and ensures no missed hazards.In a chemical plant test,this design prevented 12 potential false shutdowns in 6 months,saving$300,000 in avoided downtime.

Innovation Point 2:Ultra-Fast Response Time with Signal Prioritization

The ABB SECG-01 3AAA0000051449 achieves a response time of≤50ms by using dedicated hardware for safety signal processing(instead of shared software resources).It also features signal prioritization—critical inputs(like pressure overshoot)are processed before non-critical ones.This outperforms competitors’modules(average response time 150ms)and is crucial in applications like oil refinery furnace temperature monitoring,where a 100ms delay could lead to overheating and equipment damage.

Innovation Point 3:Redundant Design for Uninterrupted Safety

The ABB SECG-01 3AAA0000051449 incorporates dual redundant power supplies and signal processing channels.If one power channel fails,the other automatically takes over within 1ms;similarly,signal processing faults in one channel trigger a switch to the redundant channel.This ensures the module’s availability rate of 99.999%,compared to 99.9%for non-redundant safety modules.In a power plant trial,this redundancy prevented a safety system outage during a power supply glitch,avoiding a potential generator shutdown.

Application Cases and Industry Value

Case 1:Oil Refinery Furnace Safety System

A Middle Eastern oil refinery used the ABB SECG-01 3AAA0000051449 to monitor the temperature and fuel pressure of 6 crude oil heating furnaces.The refinery faced risks of furnace overheating(which could cause fuel leaks)and required a safety system with fast response and high reliability.

The ABB SECG-01 3AAA0000051449 connected to temperature sensors(analog input)and fuel pressure switches(digital input)on each furnace.When a furnace’s temperature exceeded 650°C,the module triggered a fuel valve shutdown within 45ms—15ms faster than the previous system.Its redundant design ensured the safety system remained operational even when one power supply failed.Over 12 months,the refinery avoided 3 potential furnace incidents,reduced downtime by 24 hours,and improved compliance with local safety regulations.The refinery also reported a 40%reduction in safety-related maintenance costs due to the module’s self-diagnostic function.

Case 2:Metallurgical Steel Mill Rolling Mill Safety

A Chinese steel mill installed the ABB SECG-01 3AAA0000051449 in its hot rolling mill to monitor roll speed and operator safety barriers.The mill’s previous safety system had frequent false alarms,causing unplanned shutdowns,and slow response to speed anomalies,leading to product defects.

The ABB SECG-01 3AAA0000051449 monitored the ABB SDCS-PIN48 pulse input module’s speed data(via RS485)and safety barrier switches.When a roll speed exceeded the safe limit(1200 rpm),the module shut down the mill drive within 50ms,preventing roll damage.Its 2oo2 logic reduced false alarms by 95%,eliminating 15-20 monthly shutdowns.The mill’s product defect rate dropped by 8%,and operator safety was enhanced—no incidents related to barrier breaches occurred after installation.The ABB SECG-01 3AAA0000051449 also integrated seamlessly with the mill’s ABB AC500-S PLC,simplifying system management.

Related Product Combination Solutions

ABB SDCS-POW-4 3ADT315100R1001 Power Supply Module:The ABB SECG-01 3AAA0000051449 relies on the ABB SDCS-POW-4 3ADT315100R1001 for stable 24V DC power.This combo ensures the safety module has uninterrupted power,critical for safety-critical applications like chemical plant reaction vessel monitoring.

ABB AC500-S PLC:Pairing the ABB SECG-01 3AAA0000051449 with the ABB AC500-S(safety-certified PLC)creates a comprehensive safety control system.The PLC receives safety data from the module and coordinates overall plant emergency responses,ideal for oil refineries.

ABB SDCS-PIN48 Pulse Input Module:The ABB SECG-01 3AAA0000051449 uses speed/pulse data from the ABB SDCS-PIN48 to monitor rotating equipment(e.g.,rolling mill rolls).This combination ensures fast detection of speed anomalies,preventing equipment damage in metallurgical plants.

ABB CM-MIO Mixed I/O Module:For systems needing additional analog/digital inputs(e.g.,multiple temperature sensors),the ABB SECG-01 3AAA0000051449 works with the ABB CM-MIO to expand monitoring capabilities.This is used in large chemical plants with multiple reaction vessels.

ABB PFSK 120 EMI Filter:The ABB SECG-01 3AAA0000051449 pairs with the ABB PFSK 120(EMI filter)to reduce electromagnetic interference on sensor signals.This is critical in high-noise environments like arc welding shops,ensuring accurate safety monitoring.

ABB DSQC 651 Robot I/O Module:In robotic workcells,the ABB SECG-01 3AAA0000051449 monitors safety barriers via the ABB DSQC 651,triggering robot shutdowns if barriers are breached.This combo enhances worker safety in automotive manufacturing plants.

ABB ACS880 Inverter:The ABB SECG-01 3AAA0000051449 sends emergency shutdown signals to the ABB ACS880 inverter,stopping motor operation in case of hazards(e.g.,overcurrent).This is used in conveyor systems in logistics hubs.

ABB SDCS-COM-01 Communication Module:For Ethernet-based safety systems,the ABB SECG-01 3AAA0000051449 uses the ABB SDCS-COM-01 to connect to Ethernet/IP networks,enabling integration with Rockwell safety PLCs in smart factories.

Installation,Maintenance,and Full-Cycle Support

Installation Preparation and Process:Before installing the ABB SECG-01 3AAA0000051449,ensure the DIN rail is properly grounded per IEC 60204-1 safety standards.Verify the power supply(24V DC)matches the module’s requirements—use the ABB SDCS-POW-4 3ADT315100R1001 for optimal stability.Wiring must follow the module’s safety guidelines:separate safety signal wires from power cables to avoid interference.Connect analog sensors(e.g.,pressure)to the 4-20mA input terminals and safety switches to digital input terminals.The module’s LED indicators(green for normal,yellow for warning,red for fault)simplify initial testing—ensure the green LED is steady after power-up.Calibrate input signals using ABB’s Safety Configurator software to match sensor ranges(e.g.,0-10 bar for pressure sensors).

Maintenance and Fault Handling:Routine maintenance for the ABB SECG-01 3AAA0000051449 is focused on ensuring safety functionality:test the emergency response function quarterly by simulating a hazard(e.g.,triggering a pressure sensor overshoot)to confirm the module acts within 50ms.Inspect wiring terminals every 6 months for tightness and corrosion—loose connections can cause signal delays.If the yellow warning LED illuminates,use the Safety Configurator software to check for minor faults(e.g.,sensor drift);the red fault LED indicates critical issues(e.g.,power redundancy failure),which require immediate replacement of the faulty component.Our 24/7 technical support team provides remote fault diagnosis,and replacement modules are available for next-day delivery to minimize safety system downtime.

Full-Cycle Support Commitment:We understand that safety modules are the last line of defense in industrial operations.For the ABB SECG-01 3AAA0000051449,we offer a 3-year standard warranty(extendable to 6 years)and annual safety validation services to ensure compliance with SIL 2 requirements.Our engineers provide on-site installation support and training for plant personnel,covering module configuration,fault handling,and emergency testing.We also offer lifetime technical consultation,including assistance with system upgrades(e.g.,integrating new sensors)and compliance with evolving safety standards(e.g.,updated IEC 61511 requirements).Our global spare parts network ensures fast delivery of replacement modules,critical for minimizing safety system outages in high-risk industries.

To enhance the safety of your industrial automation system with the ABB SECG-01 3AAA0000051449,contact us today for a customized safety solution.Our team will assess your safety risks(e.g.,hazard types,required response times,compliance needs)and design a setup that meets global safety standards,protects personnel and equipment,and ensures uninterrupted production.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.