Application Scenarios

Within a power generation plant’s turbine control system, the Advant Controller 410 is responsible for executing critical speed and sequencing logic. The integrity of this controller is paramount. The ABB SPNPM22 power supply module is installed inside the controller’s main rack. It takes the plant’s 110VAC or 125VDC control power and converts it into the precise, filtered +5V logic power and +24V bus power needed by the CPU module, communication couplers, and other internal cards. Its design includes overvoltage and overload protection to safeguard the sensitive electronics. If the plant experiences a brief voltage sag on the control bus, the SPNPM22’s hold-up capacity and regulation ensure the controller continues to operate without a glitch, preventing an unnecessary turbine trip. It solves the pain point of providing clean, reliable power in an electrically noisy industrial environment, forming the stable foundation upon which all control functions depend.

Parameter

Technical Principles and Innovative Values

The ABB SPNPM22 is engineered as a robust, system-integrated power conversion unit, emphasizing reliability, protection, and precise regulation for sensitive digital control electronics.

Innovation Point 1: Dual-Output, Tightly Regulated Design. Unlike a generic power supply, the SPNPM22 is specifically designed to generate the two critical voltage rails required by digital control systems: a very stable +5V for CPU and memory logic, and a separate +24V for field interface circuits and internal bus communication. It incorporates high-quality filtering and precise regulation circuits to ensure these outputs remain within a tight tolerance (e.g., ±1%) despite fluctuations in the input AC line. This clean power is essential for preventing memory errors, communication glitches, and processor resets.

Innovation Point 2: Integrated System Protection and Diagnostics. The module is built with comprehensive protective features that safeguard both itself and the expensive controller cards it powers. This includes current-limiting overload protection, output overvoltage clamping, and short-circuit protection. These features prevent a fault in a single I/O or communication card from bringing down the entire controller by causing a catastrophic power supply failure. Status LEDs provide immediate local diagnostics (e.g., “Power Good,” “Fault”), allowing for quick identification of power-related issues.

Innovation Point 3: Seamless Integration and Form Factor. The SPNPM22 is not an external box; it is designed to mount directly into the controller or OCS rack’s backplane, connecting via a dedicated power bus. This integrated design saves panel space, simplifies overall system wiring (only the incoming AC/DC power needs to be routed to the rack), and improves reliability by eliminating external cabling and connections for the internal DC power distribution. Its form factor and electrical interface are optimized specifically for the thermal and electrical environment of the Advant/MOD 300 rack.

Application Cases and Industry Value

Case Study: Enhancing Reliability in a Steel Mill BOF Control System

The Basic Oxygen Furnace (BOF) control system in a steel mill, based on an ABB MOD 300 platform, experienced intermittent controller resets during large motor starts, which caused process upsets. Investigation pointed to voltage dips on the plant’s 110VAC control circuit that were overwhelming the existing power supply’s hold-up capability.

Process & Improvement: The aging power supply units in several critical controller racks were replaced with new ABB SPNPM22 modules. The SPNPM22’s superior input voltage range and robust filtering were specifically chosen to handle the harsh electrical environment. After installation, the system’s immunity to voltage sags improved dramatically. During the next scheduled motor start of a large fume extractor fan, the voltage on the control bus dipped by 20%, but the SPNPM22 maintained its output rails within specification. The controller operated without interruption, and the BOF process continued smoothly. This upgrade resulted in the elimination of unexplained controller resets, leading to improved process stability, higher quality steel batches, and avoidance of costly production halts. The SPNPM22 provided the reliable power foundation that the advanced control logic required.

Related Product Combination Solutions

The ABB SPNPM22 is a foundational component that powers other critical modules within the Advant Controller 410/MOD 300 ecosystem.

ABB Advant Controller 410 (e.g., AC410 CPU): The main processor module that relies on the clean +5V power from the SPNPM22 for its operation.

ABB 70EB01C-ES / 70EB02C-ES: Digital I/O modules. They utilize the +24V bus power from the SPNPM22 for field-side electronics and signal conditioning.

ABB 70EA01C-ES: Analog I/O module. Depends on the regulated voltages from the SPNPM22 for its precision measurement circuits.

ABB Communication Modules (e.g., for Fieldbus): Any communication interface card in the rack (e.g., for PROFIBUS) is powered by the SPNPM22.

ABB OCS/Controller Rack (e.g., EU91A Chassis): The physical enclosure and backplane that houses the SPNPM22 and all other modules, distributing the power it generates.

ABB System Power Distribution Unit: In larger configurations, an upstream system power unit might provide the 110VAC or 125VDC input to the SPNPM22 and other racks.

ABB Redundant Power Supply System: For high-availability applications, two SPNPM22 modules (or similar) can be configured in a redundant (N+1) setup within the same rack, ensuring continuous operation if one power supply fails.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB SPNPM22 must be performed by qualified personnel with the system power disconnected. The module is carefully inserted into its designated slot in the controller rack until it firmly seats into the backplane connector. The incoming AC or DC power wiring must be connected to its terminal block according to the system wiring diagrams, adhering to all local electrical codes. Proper grounding is critical. Once installed and powered, the “Power Good” LED should illuminate, indicating successful operation.

Maintenance is primarily preventive and monitoring-based. The key activity is to ensure the cooling vents on the power supply and rack are not obstructed. The status LED should be periodically checked. Unlike field I/O modules, power supplies have a finite lifespan, primarily for internal components like electrolytic capacitors. Proactive replacement as part of a lifecycle management program is recommended before end-of-life failure. Should a module fail, it is a swap-out procedure (with system power off) after transferring the load to a redundant unit if available. We provide comprehensive support for the SPNPM22. including technical documentation, spare parts sourcing, and expert consultation on power system health and redundancy strategies for your legacy Advant/MOD 300 systems.

Ensure the stable and reliable operation of your control system’s core. Contact us for genuine ABB SPNPM22 power modules and power system consultancy.

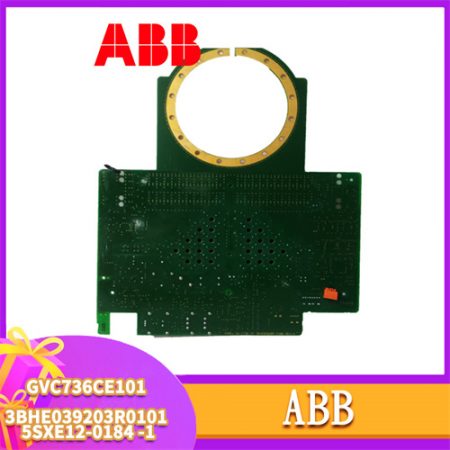

SPNPM22

SPNPM22

Reviews

There are no reviews yet.