Description

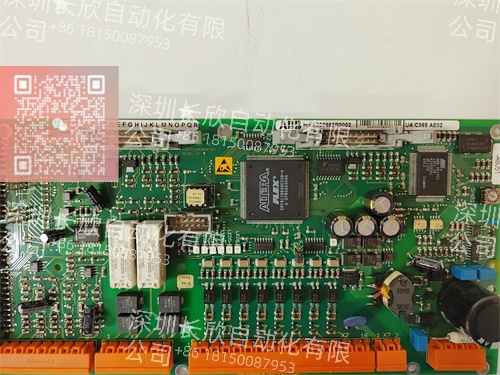

The ABB UAC389AE02 HIEE300888R0002 is a high-performance controller module designed for ABB’s process automation systems, specifically for the Advant Controller series and compatible with AC 800M platform applications. This controller serves as the intelligent core of Distributed Control System (DCS) applications, executing complex control logic, sequence operations, and regulatory algorithms for critical industrial processes. It provides reliable, deterministic control performance for applications in power generation, oil & gas, chemical processing, and other demanding industrial environments.

Application Scenarios

In a large-scale power generation plant, the coordinated control of boilers, turbines, and auxiliary systems requires precise, millisecond-level synchronization and fault-tolerant operation. A system failure could lead to grid instability or forced shutdowns costing millions. The control engineers implemented the ABB UAC389AE02 HIEE300888R0002 controller as part of a redundant controller pair managing the boiler combustion control system. The module’s deterministic execution ensured precise fuel-air ratio control, while its redundant design eliminated single points of failure. During a planned maintenance window, engineers could perform firmware updates on the standby controller without interrupting the live process. The controller’s robust design provided 99.999% availability over 5 years of continuous operation, directly contributing to plant reliability and operational efficiency.

Technical Principles and Innovative Values

Innovation Point 1: Deterministic Control Architecture for Critical Processes. The UAC389AE02 implements a hard real-time operating system that guarantees deterministic execution of control algorithms. This means critical control loops execute with predictable, microsecond-level timing regardless of system load. The controller uses priority-based task scheduling and dedicated interrupt handling to ensure that time-critical functions like safety interlocks and regulatory control always receive processing priority, making it ideal for applications where timing precision directly impacts process safety and product quality.

Innovation Point 2: Seamless Redundancy and High Availability Design. The controller features advanced redundancy capabilities with automatic bumpless switchover. In redundant configurations, two UAC389AE02 controllers operate in synchronized master-standby mode with continuous data mirroring. If the master controller fails, the standby controller takes over control within milliseconds without process disturbance. The system maintains full controller state information during switchover, ensuring continuous execution of batch processes and sequential operations—a critical feature for processes that cannot tolerate interruptions.

Innovation Point 3: Advanced Diagnostic and Maintenance Capabilities. The module incorporates comprehensive self-diagnostics and health monitoring that continuously checks processor status, memory integrity, communication links, and I/O subsystem health. Detailed diagnostic information is available through engineering tools and operator interfaces, enabling predictive maintenance. The controller supports online modification capabilities, allowing control strategies to be modified and tested while the process remains operational. Firmware updates can be applied to standby controllers in redundant systems without process interruption.

Application Cases and Industry Value

Case Study: Pharmaceutical Batch Process Automation.

A multinational pharmaceutical company implemented a new bioreactor facility for vaccine production requiring FDA 21 CFR Part 11 compliance. The batch processes demanded exact recipe execution, complete audit trails, and absolute reliability.

Solution: Each bioreactor train was controlled by redundant ABB UAC389AE02 HIEE300888R0002 controllers. The controllers executed complex batch sequences with precise temperature, pressure, and pH control loops. The deterministic architecture ensured that time-critical sterilization phases maintained exact temperature profiles. The redundancy provided the required availability for continuous batch operations.

Outcome and Value: The system achieved 100% batch success rate with perfect recipe reproducibility. During a plant-wide power disturbance, the redundant controllers performed seamless switchovers without losing batch state information. The facility achieved regulatory approval in record time, with auditors specifically noting the reliability and traceability of the control system. The plant manager estimated that the system’s reliability contributed to 15% higher overall equipment effectiveness compared to previous generation systems.

Related Product Combination Solutions

ABB S800 I/O System: Distributed I/O system connecting field instruments to the UAC389AE02 controller via high-speed fieldbus networks, providing scalable I/O capacity for large installations.

ABB CI854 Communication Interface: PROFIBUS DP master module enabling connection to field devices, drives, and other PROFIBUS-compatible equipment in the process environment.

ABB TP830 Operator Panel: Local operator interface providing HMI functionality, alarm management, and operator controls at the controller level for local operation and monitoring.

ABB 800xA DCS: Extended Automation System providing engineering tools, operator workplace, and information management that integrates seamlessly with the UAC389AE02 controller for complete DCS solutions.

ABB Redundancy Kit: Hardware and software package enabling hot standby redundancy configuration for maximum system availability and fault tolerance.

ABB Control Builder: Engineering tool for configuration, programming, and maintenance of the UAC389AE02 controller and associated I/O systems.

Installation, Maintenance, and Full-Cycle Support

Installation: The UAC389AE02 controller installs in a standard 19-inch rack with proper ventilation and clearances. The module requires clean, stable power supply (typically 24V DC) with appropriate protective devices. Network connections should use industrial-grade cabling with proper grounding and shielding. The controller must be properly configured for the specific application using Control Builder engineering tools before commissioning.

Maintenance: The controller requires minimal routine maintenance. Key activities include:

Regular cleaning of air filters and heat sinks

Monitoring of diagnostic messages and system logs

Periodic verification of redundancy switchover functionality

Regular backup of application software and configuration

Firmware updates during planned maintenance windows

Periodic testing of uninterruptible power supplies

Troubleshooting: The controller provides comprehensive diagnostic information through status indicators, system logs, and engineering tools. Common issues include communication failures, power supply problems, or memory errors—all of which generate specific error codes and diagnostic information. The hot-swappable design allows for module replacement without system shutdown in redundant configurations.

Full-Cycle Support: We provide complete lifecycle support including:

System design and configuration assistance

Genuine ABB components with full documentation

Application software development and testing support

Commissioning and startup assistance

Training for operations and maintenance staff

24/7 technical support and emergency services

Spare parts management and repair services

Migration services for system upgrades and expansions

Reviews

There are no reviews yet.