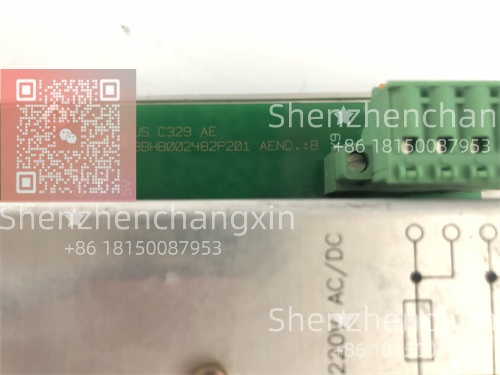

Product Overview

The ABB USC329AE01 is a high-integrity, high-availability triple-redundant (TMR) safety controller module, part of ABB’s renowned System 800xA High Integrity or Safeguard 400 series safety systems. It utilizes a “two-out-of-three” (2oo3D) voting architecture and is the core hardware component for Safety Instrumented Systems (SIS) and Emergency Shutdown Systems (ESD). It is specifically designed to perform Safety Instrumented Functions (SIF) at SIL 3 level, providing the highest level of safety protection for the most critical industrial processes.

Core Functions and Value

The core value of this module lies in its fail-safe, single-point-of-failure-free design. Three independent processing channels execute the same safety logic in parallel. An output voter compares the results from the three channels in real time, and a valid output command is generated only when two or more channels agree. This design ensures that even if one channel experiences any failure (including dangerous latent failures), the system can still correctly execute safety actions (shutdown or interlock), thus protecting personnel, the environment, and assets, and minimizing unplanned shutdowns caused by a single failure. Technical Specifications

Parameter Category

Specific Description

Product Model

USC329AE01

Manufacturer

ABB Process Automation

System Platform

System 800xA High Integrity or Safeguard 400

Safety Level

Complies with IEC 61508 / IEC 61511 standards, supporting up to SIL 3 safety integrity level

Architecture

Triple Modular Redundancy (TMR), 2oo3D voting

Processor

Multi-core high-performance safety processor, independent for each channel

Memory

Redundant safety memory with error checking and correction (ECC)

Diagnostic Coverage

Extremely high (>99%), achieved through online, periodic comprehensive self-diagnostics

Communication Interface

Supports secure Ethernet and secure communication with other safety controllers/standard controllers

Operating Temperature

0°C to +60°C (standard industrial range)

Certifications

Certified by international authoritative safety certification bodies such as TÜV

Application Scenario

Scenario: Emergency Shutdown (ESD) system on an offshore oil platform

On offshore drilling platforms, control of high-pressure oil and gas wellheads is crucial. Once the pressure safety valve (PSV) sensor detects a dangerous overpressure, the signal is sent to the safety controller composed of USC329AE01. Three independent channels immediately perform parallel calculations, making a shutdown decision within milliseconds. Even if one channel experiences a momentary calculation error due to strong electromagnetic interference, the “shutdown” command from the other two normal channels will still be the majority, and the system will immediately and unambiguously trigger the emergency shutdown of the main pneumatic valve, shutting off the wellhead and preventing a blowout. Its extremely high diagnostic coverage can detect and report any channel failure in real time, prompting maintenance and ensuring that the system is always in a “ready” state, perfectly addressing the core pain points of “must be foolproof” and “must be available at all times” in high-risk environments.

Technical Advantages and Innovative Value

Triple-redundant fault-tolerant architecture for maximum safety

The core innovation lies in its physically isolated, parallel computing, and real-time voting hardware architecture. Three identical channels are physically and electrically isolated, running independent operating systems and applications. The voter compares the results at a very high frequency. This design allows the system to tolerate not only random hardware failures but also common-cause failures (such as power surges and software defects). Compared to dual-redundancy (1oo2D) systems, the TMR architecture provides higher availability while maintaining equally high safety, as it allows one channel to be taken offline for maintenance without affecting the safety function.

Deep Integration with 800xA for Unified Safety and Control

Unlike independent safety PLCs, the USC329AE01 is seamlessly integrated into ABB’s System 800xA extended automation platform. This provides a unified engineering environment: safety logic and basic process control logic (BPCS) can be configured, simulated, and tested using the same engineering tools (such as Control Builder for Safety), significantly reducing integration complexity and the risk of human error. At the same time, operators can view process alarms and safety alarms simultaneously on a unified interface, enabling global situational awareness and faster, more accurate decision-making in emergencies.

Comprehensive Predictive Diagnostics and Lifecycle Management

The module includes comprehensive diagnostic functions beyond the conventional, including processor, memory, communication, I/O readback, and watchdog. These diagnostics not only detect faults but also differentiate between safety faults (leading to safe shutdown) and dangerous faults (potentially leading to functional failure). Through advanced diagnostic data such as Safety Demand Rate (SDR) and Mean Time To Failure (MTTF), the system can assess its own health status, supporting predictive maintenance. All configuration changes and access are managed through strict electronic signatures and audit trails, meeting the full lifecycle management requirements of functional safety and providing a complete chain of evidence for audits and compliance.

Industry Application Case Study

Case Study: Safety Interlock System Upgrade for a Large Chemical Plant Polymerization Reactor

A large chemical company’s existing safety system was outdated, had high maintenance costs, and lacked compliance certification. Its core polymerization reactor posed an explosion risk if it went out of control. The company upgraded its SIS system using the ABB USC329AE01.

After implementation:

Safety Compliance: The new system easily achieved SIL 3 certification, meeting international safety standards and resolving compliance issues.

Reduced Unplanned Downtime: In an incident caused by a transient false signal from a sensor, the triple-redundancy architecture correctly identified it as a “false signal,” preventing a false shutdown and avoiding production losses exceeding 2 million RMB in a single incident. In the event of a real cooling water failure, the system reliably interlocks and shuts down within 50ms.

Improved operational efficiency: The unified 800xA platform improves collaboration efficiency between process personnel and safety engineers by 30%. Advanced diagnostic functions provided a one-week advance warning of potential degradation in a communication module, enabling planned replacement.

Customer value: While improving safety levels, it is expected to reduce unplanned shutdowns by 1-2 times per year, directly avoiding significant economic losses, and gaining verifiable safety management capabilities, enhancing corporate reputation and insurance ratings.

Supporting Solutions

Safety I/O Modules: Such as SAF315AE01 or SAF316AE01. providing SIL 3 certified analog/digital input and output, connected to USC329AE01 via a safety network to form a complete SIS.

Engineering and Operation Station Software: Control Builder for Safety is used for safety application programming and hardware configuration; the Operate client provides the operating interface, both within the 800xA framework.

Communication Gateway: Such as CI869K, used to connect third-party devices or for secure communication with higher-level management systems (such as fire and gas systems).

Power Supply and Rack: Redundant 24VDC safety power supply and dedicated safety controller rack provide high-availability power supply and physical installation foundation for the entire safety system.

Simulation and Testing Tools: Used for online simulation and testing of SIS logic without shutting down the system, verifying its functional integrity.

Installation, Commissioning and Maintenance Support

Installation and Commissioning

System Design: SIL verification and system design are performed by engineers with functional safety qualifications (such as TÜV FSEng), generating a safety requirements specification.

Hardware Installation: Install the USC329AE01 module into the designated safety rack, connecting redundant power supplies and networks. ABB’s installation guidelines and grounding specifications must be strictly followed to resist electromagnetic interference.

Software Configuration: Use Control Builder for Safety for hardware configuration, safety logic programming (usually using Function Block Diagram (FBD) or Ladder Diagram (LD)), and defining secure communication.

Verification and Validation: This is a critical stage. It includes Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT), requiring strict adherence to test procedures to verify each Safety Instrumented Function (SIF), and generating a complete test report. Finally, an independent assessment body conducts a safety audit. Maintenance and Support

Online Diagnosis and Prediction: Utilize the system’s rich diagnostic information and equipment status monitoring functions to plan predictive maintenance.

Periodic Functional Testing: Regularly test the SIF (Safety Instrumented Function) according to the test cycle calculated in the safety requirements specification to maintain the required PFD (Probability of Failure on Demand) level. Testing can be performed through partial stroke testing or with the assistance of simulation tools.

Change Management: Any modifications to the safety logic or hardware must follow a strict Management of Change (MOC) process, including impact analysis and necessary verification testing.

Professional Services: We provide full lifecycle services, from initial safety assessment, engineering implementation, commissioning, to subsequent maintenance, periodic testing, and personnel training. Our team of engineers is familiar with relevant safety standards and can ensure your SIS system remains in optimal and compliant operating condition.

Reviews

There are no reviews yet.