Engineered for use in process control,energy management,and manufacturing automation,the ABB GJR2265600R101 supports up to four independent channels of RTD or thermocouple inputs,offering flexibility in sensor configuration and multi-point temperature monitoring.It is particularly suited for applications requiring tight temperature control,such as in chemical reactors,HVAC systems,food and beverage processing,and power generation.The module connects directly to the AC 500 backplane,drawing power from the system bus and communicating with the CPU via a high-speed internal data link,eliminating the need for external power supplies and reducing wiring complexity.

With built-in signal conditioning,linearization,and cold-junction compensation(for thermocouples),the VT371DR101 ensures high measurement accuracy and stability over time and temperature.Its compliance with international standards such as IEC 61000 for electromagnetic compatibility(EMC)and reinforced isolation rated up to 2500 VAC makes it suitable for deployment in industrial installations with high levels of electrical interference or ground potential differences.Designed for durability and long-term reliability,the ABB GJR2265600R101 is housed in a compact,DIN rail-mountable enclosure that fits seamlessly into standard control cabinets,making it a trusted solution for engineers seeking precise,scalable,and maintainable process instrumentation.

Technical Specifications

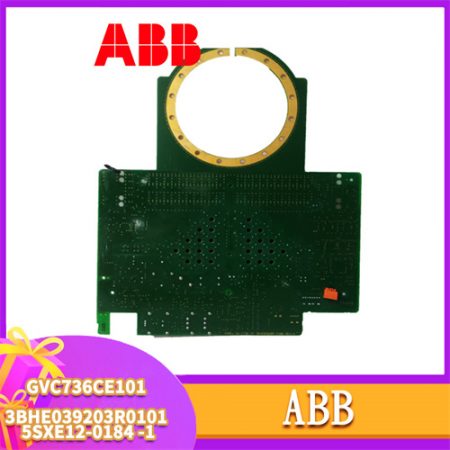

Product Model|GJR2265600R101/VT371DR101

Manufacturer|ABB

Product Type|Analog Input Module(RTD/Thermocouple)

Series/Platform|AC 500 PLC System

Number of Channels|4 differential inputs

Input Types Supported|

RTD:Pt100,Pt1000,Ni100,Cu10

Thermocouple:Types J,K,L,U,T,E,N,S,R,B(with cold-junction compensation)

Measurement Range(RTD)|-200°C to+850°C(depending on sensor type)

Resolution|16-bit

Accuracy|±0.1%of full scale(typical at 25°C)

Sampling Rate|250 ms per 4 channels(62.5 ms per channel)

Signal Isolation|Galvanic isolation(2500 VAC RMS between channels and backplane)

Cold Junction Compensation|Integrated,automatic

Data Format|Scaled engineering units(°C or°F)via PLC register

Operating Temperature|0°C to 60°C(32°F to 140°F)

Storage Temperature|-40°C to 85°C(-40°F to 185°F)

Humidity|5%to 95%RH,non-condensing

Mounting|35 mm DIN rail

Power Supply|24 VDC via backplane

Certifications|CE,UL,CSA,IEC/EN 61000(EMC),RoHS compliant

Main Features and Advantages

The ABB GJR2265600R101(VT371DR101)stands out for its high measurement accuracy and built-in intelligence,which significantly reduce the engineering effort required for temperature monitoring systems.Each channel performs automatic linearization of RTD curves and thermocouple voltage-to-temperature conversion,delivering ready-to-use engineering values(in°C or°F)directly to the PLC CPU.This eliminates the need for complex scaling or lookup tables in the control program,streamlining development and reducing commissioning time.

A key advantage is the module’s galvanic isolation,which protects the central controller from voltage transients,ground loops,and surges that can originate in field wiring.This isolation enhances system reliability and prevents measurement errors caused by common-mode noise—especially important in environments with variable frequency drives(VFDs),large motors,or high-power switching equipment.The differential input design further improves noise rejection by canceling out interference picked up along the signal path.

The VT371DR101 also features comprehensive diagnostics,including open-wire detection,sensor burnout monitoring,and internal hardware fault reporting.These diagnostic capabilities are accessible via the PLC’s memory and can trigger alarms or automatic responses,enabling predictive maintenance and minimizing unplanned downtime.The module supports hot-swap capability in redundant configurations,allowing replacement without shutting down the entire control system—a critical feature in continuous-process industries.

Its seamless integration with ABB Automation Builder software enables easy configuration,calibration,and online monitoring of all four channels.Engineers can assign sensor types,set filtering parameters,and view real-time data directly from the engineering workstation.With its robust construction,wide sensor compatibility,and precision performance,the ABB GJR2265600R101 is an ideal choice for applications demanding dependable and accurate temperature measurement across diverse industrial sectors.

Application Field

The ABB GJR2265600R101 is widely used in industrial applications where precise temperature monitoring is essential for product quality,process efficiency,and equipment protection.In process industries such as chemical,petrochemical,and pharmaceutical manufacturing,it monitors reactor temperatures,distillation columns,and storage tank conditions,ensuring processes remain within safe and optimal operating ranges.

In food and beverage production,the module ensures compliance with strict hygiene and safety standards by accurately controlling pasteurization,sterilization,fermentation,and refrigeration processes.Its ability to interface with Pt100 sensors—commonly used in hygienic applications—makes it a preferred choice in washdown environments.

Within energy and power generation,the VT371DR101 monitors bearing temperatures,cooling systems,and boiler feedwater,helping prevent equipment failure and support condition-based maintenance programs.In HVAC and building automation systems,it regulates air handling units,chillers,and heating circuits for optimal energy efficiency and occupant comfort.

The module is also deployed in water and wastewater treatment plants to monitor digester temperatures,pump seals,and sludge heating systems.For original equipment manufacturers(OEMs)building industrial machinery,the ABB GJR2265600R101 offers a scalable and certified solution for integrating temperature feedback into machine control logic.Whether used in new installations or system upgrades,this module provides a future-ready,high-performance interface for analog process signals in the ABB AC 500 ecosystem.

Related Products

ABB VT371AR101(GJR2265500R101)–Analog output module counterpart,used to drive temperature controllers,valves,or indicators based on PLC logic.

ABB AI533–General-purpose analog input module for 4–20 mA or 0–10 V signals,often used alongside the VT371DR101 for mixed signal types.

ABB AC500-S–Safety PLC CPU that can integrate temperature data from the VT371DR101 for safety interlocks(e.g.,overtemperature shutdown).

ABB CP571/CP677–Central processing units for the AC 500 series,used to execute control logic based on temperature inputs.

ABB DM582–Digital I/O module for discrete signals,commonly paired with the VT371DR101 in comprehensive control panels.

ABB GJR5-250500-R0202–Safety I/O module used in conjunction with temperature monitoring for emergency shutdown systems.

ABB Automation Builder–Engineering software platform used to configure,program,and diagnose the ABB GJR2265600R101 and other AC 500 components.

ABB RTD Sensor Kits(e.g.,Pt100 3-wire/4-wire)–Compatible field sensors optimized for use with the VT371DR101 module.

Installation and Maintenance

Pre-installation preparation:Before installing the ABB GJR2265600R101,ensure the control cabinet is powered off and the DIN rail is securely mounted.Verify that the AC 500 PLC rack has available slots and compatible firmware.Use shielded,twisted-pair cables for all sensor connections,and follow ABB’s recommended wiring practices—especially for 3-wire or 4-wire RTD configurations to minimize lead resistance errors.Ground the cable shield at one end only(typically at the module side)to prevent ground loops.Confirm the sensor type(e.g.,Pt100,Type K)in the configuration software before powering up.

Maintenance recommendations:The VT371DR101 requires minimal maintenance but should be included in routine system diagnostics.Use Automation Builder to monitor channel status,check for open-wire faults,and verify measurement stability.Inspect terminal blocks annually for tightness and signs of corrosion,particularly in humid environments.If a channel fails or reports inconsistent values,verify sensor integrity and wiring continuity first.Due to its hot-swap capability(in supported configurations),the module can be replaced without stopping the entire PLC system—ideal for minimizing downtime in critical processes.Keep spare modules stored in anti-static packaging in a dry,temperature-controlled environment.

Product Guarantee

We provide a full product guarantee for every ABB GJR2265600R101(VT371DR101)module supplied,ensuring authenticity,functionality,and compliance with ABB’s technical specifications.Each unit is sourced through authorized channels and undergoes rigorous inspection prior to shipment.Our guarantee covers defects in materials and workmanship and includes access to technical support for configuration,integration,and troubleshooting by experienced automation specialists.In the event of a verified fault,we offer prompt replacement or return authorization to minimize operational impact.By delivering genuine,certified ABB VT371DR101 modules backed by quality assurance and responsive service,we support the long-term reliability and performance of your industrial control systems.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

Reviews

There are no reviews yet.