Application Scenarios

At a 600 MW combined-cycle power plant in Germany, inconsistent steam temperature control was causing turbine stress and reduced efficiency. The root cause? Aging analog output cards with drift beyond ±1%, leading to valve positioning errors. After upgrading to ABB XVC767AE102 3BHB007209R0102 modules, the plant achieved:

±0.1% full-scale accuracy across all 8 channels

Real-time HART-based valve diagnostics during operation

Automatic fault alarms for open-circuit or overrange conditions

Seamless integration into 800xA for trend analysis and loop tuning

During a grid frequency event, the XVC767AE102 precisely modulated bypass valve positions within 50 ms, stabilizing steam pressure and preventing a trip. Over 18 months, zero AO-related failures occurred—validating its role as a high-integrity output layer in critical control strategies.

Technical Principles & Innovation Highlights

Per-Channel Intelligence: Each output includes independent DACs, drivers, and diagnostic circuits—failure in one channel does not affect others.

True HART Transparency: Enables live device configuration and diagnostics via 800xA Asset Optimization without loop interruption.

Predictive Maintenance Ready: Continuous monitoring of output current, voltage drop, and temperature allows early detection of failing valves or wiring degradation.

Seamless Redundancy: In redundant mode, both primary and standby modules track each other; switchover is bumpless (<1 ms). High Immunity: Designed for electrically noisy environments (e.g., near VFDs or switchgear) with >100 dB common-mode rejection.

Typical Use Cases

Control valve positioning in boiler feedwater, fuel gas, or steam systems

Speed reference output to VFDs in pumping stations

Actuator command signals in ESD bypass systems

Analog setpoint transmission to legacy subsystems

Redundant AO for critical turbine inlet guide vanes (IGVs)

Related Product Combination Solutions

ABB AC 800M CPU (e.g., PM825 3BSE010796R1): Host controller for logic execution

ABB CI854A 3BSE020510R1: PROFIBUS DP communication module linking S800 I/O to AC 800M

ABB XTU767 3BHB007210R1: Termination unit with screw terminals and per-channel LEDs for XVC767AE102

ABB 800xA System 6.1+: Unified engineering and operations platform with HART Device Manager

ABB Positioners (e.g., TZIDC): Smart valve controllers leveraging HART over the AO loop

ABB S800 I/O Baseplate (e.g., TB820): For secure DIN-rail mounting and backplane connectivity

Installation, Maintenance & Lifecycle Support

The XVC767AE102 installs into an XTU767 termination unit, which provides field wiring access and status indication. Configuration is performed in Control Builder M (part of 800xA Engineering), where engineers define range, fail-safe behavior (e.g., hold/zero/scale), and HART parameters.

Key maintenance advantages:

Hot-swap capable: Replace module without powering down the I/O station

Auto-calibration: Factory-trimmed; no manual calibration needed during service life

Remote Diagnostics: View channel status, current output, and fault codes directly in 800xA Operator Workplace

Our global support team offers:

Pre-deployment loop integrity testing

Redundancy validation and bumpless transfer verification

Lifecycle management for obsolescence planning

Every XVC767AE102 3BHB007209R0102 undergoes rigorous burn-in and functional testing to ensure long-term stability in mission-critical applications.

Summary

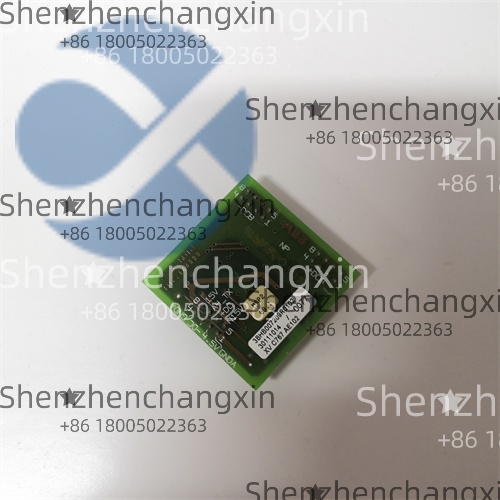

The ABB XVC767AE102 3BHB007209R0102 sets the standard for precision, reliability, and intelligence in analog output technology. By combining high-density I/O, HART-enabled diagnostics, and SIL 2 readiness, it empowers plants to achieve tighter control, reduce unplanned downtime, and extend asset life—all within the scalable architecture of the ABB 800xA ecosystem.

Ready to upgrade your analog output infrastructure? Contact us for genuine, tested XVC767AE102 modules with full technical documentation, configuration support, and global warranty coverage.

Reviews

There are no reviews yet.