Application Scenarios

At a combined-cycle power plant in Texas, aging Mark VI controllers were upgraded to Mark VIe while retaining thousands of existing field instruments. Engineers leveraged the ALSTOM AH116-2 modules—already installed and wired—to seamlessly bridge legacy 4–20 mA pressure and temperature transmitters into the new TMR (Triple Modular Redundant) architecture. Because the AH116-2 supports channel-level diagnostics and hot-swap replacement, technicians swapped faulty cards during live operation without tripping the turbine. This continuity prevented an estimated $ 1.2M in lost revenue per unplanned outage—proving that even “passive” I/O modules like the AH116-2 are pivotal to operational resilience in mission-critical energy infrastructure.

Technical Principles and Innovative Values

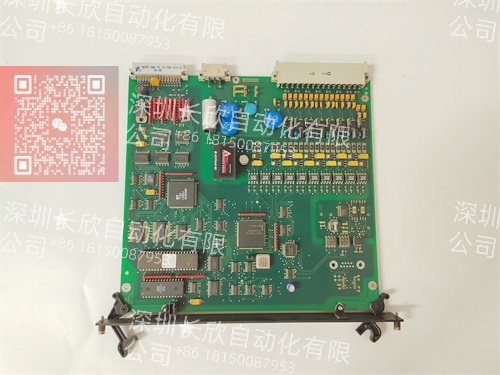

Innovation Point 1: TMR-Ready Signal Integrity – The AH116-2 delivers synchronized, time-stamped analog samples across three redundant controller racks, enabling true voting logic for turbine trip decisions—critical for SIL 3 compliance in overspeed or flameout scenarios.

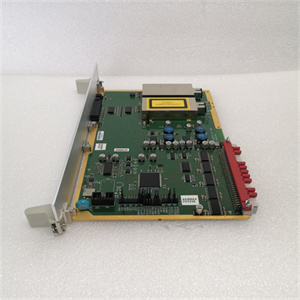

Innovation Point 2: Field-Wiring Preservation – By maintaining pin compatibility with earlier ALSTOM I/O generations, the AH116-2 allows plants to modernize control logic without rewiring field devices—a savings of weeks in labor and millions in cabling costs.

Innovation Point 3: Embedded Diagnostics – Each channel reports open-circuit, short-circuit, and out-of-range conditions to the Mark VIe controller, enabling predictive maintenance before sensor drift causes performance degradation.

Innovation Point 4: Noise Immunity for Turbine Environments – With >80 dB common-mode rejection and shielded backplane connectors, the AH116-2 operates reliably near high-voltage exciters and variable-frequency drives where EMI would cripple standard I/O.

Application Cases and Industry Value

In a European district heating plant running 24/7 through winter, a AH116-2 module detected a slow drift in a steam header pressure transmitter due to condensate buildup. The Mark VIe system flagged the anomaly days before it would have triggered a false trip, allowing maintenance during a scheduled soot-blowing window. Over five years, similar early warnings from AH116-2-equipped channels reduced unscheduled outages by 37%. In another case, a Middle Eastern IPP used AH116-2 modules to integrate legacy ALSTOM turbines into a unified GE control room—demonstrating cross-generational interoperability that extended asset life by over a decade.

Related Product Combination Solutions

GE IS200TVIHA1B: Terminal board specifically designed for AH116-2 field wiring with screw terminals and labeling

GE Mark VIe Controller (VCMI, VPRO, VSVO): Main processors that acquire data from AH116-2 in TMR configuration

ALSTOM AH115-2: 8-channel analog output counterpart often used alongside AH116-2 for closed-loop control

GE IS200SPROH1B: Speed processor module that may use AH116-2 inputs for auxiliary speed sensors

ABB UFC762AE101: In hybrid plants, AH116-2 data can be gatewayed to ABB DCS via OPC for enterprise visibility

Rockwell 1756-IF16: Functional alternative in non-turbine applications—but not TMR or Mark VI compatible

GE ToolboxST: Engineering software used to configure, calibrate, and diagnose AH116-2 channels remotely

Phoenix Contact MC 1.5/…-ST: Terminal blocks compatible with AH116-2’s terminal board for secure field connections

Installation, Maintenance, and Full-Cycle Support

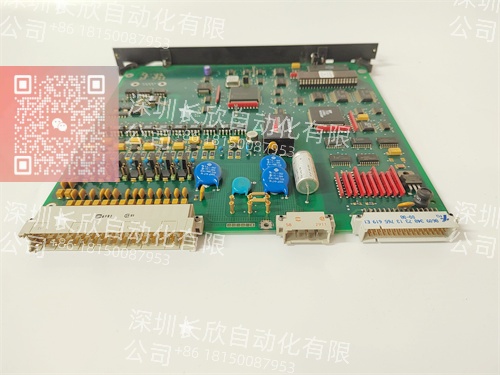

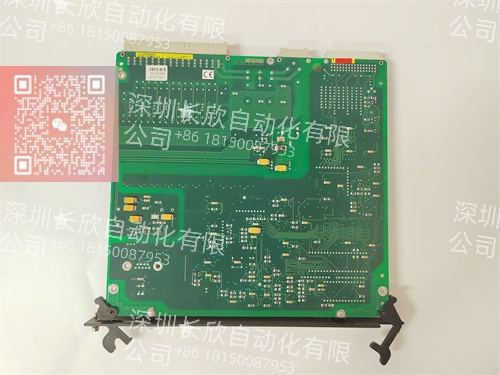

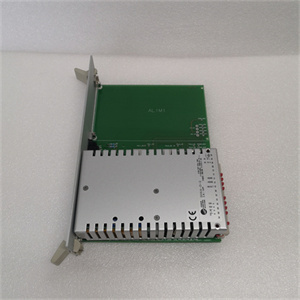

Installing the AH116-2 involves sliding it into a designated slot in the Mark VI or Mark VIe I/O chassis and securing it with the front latch. Field wiring connects via a removable terminal board (e.g., IS200TVIHA1B), enabling quick swaps without disturbing cables. Calibration is performed digitally through ToolboxST, eliminating potentiometer adjustments.

For maintenance, the module supports hot removal: if a fault LED illuminates, the unit can be replaced while the turbine runs—provided redundancy is active. We offer comprehensive lifecycle support for AH116-2. including authenticity verification (to avoid counterfeit units), functional testing with simulated turbine signals, firmware/hardware revision matching, and cross-reference assistance for obsolescence management. Whether you’re sustaining a legacy ALSTOM fleet or integrating into a modern GE ecosystem, our team ensures your AH116-2 modules deliver decades of dependable service.

Contact us for a customized solution based on ALSTOM AH116-2—whether you need spare modules for emergency replacement, engineering support for Mark VIe migration, or lifecycle planning for your turbine control I/O infrastructure.

Reviews

There are no reviews yet.