Application Scenarios

In a large manufacturing plant, the main 11kV incoming feeder and several critical outgoing circuits are protected by ALSTOM AB121 relays. During a phase-to-phase fault caused by insulation failure on a cable, the relay’s sensitive and fast overcurrent element (50/51) detected the abnormal current. Using its high-accuracy digital signal processing, it calculated the current magnitude, compared it to the pre-set time-current curve, and issued a trip command to the circuit breaker in 35 milliseconds—well before the fault could cause thermal damage to the switchgear or a plant-wide blackout. The event was time-stamped and logged in the relay’s non-volatile memory, providing the maintenance team with crucial data (fault current, type, time) for rapid analysis and root cause investigation, minimizing unplanned downtime.

Technical Principles and Innovative Values

Innovation Point 1: Adaptive Protection with Advanced Logic. The ALSTOM AB121 moves beyond fixed settings with programmable logic. Engineers can use its configurable logic gates, timers, and latches to create custom protection schemes. For example, they can implement “fuse blow” logic, where a blown fuse on a transformer LV side is detected by an undercurrent condition, blocking unnecessary feeder tripping. This programmability allows the relay to be tailored to complex network topologies, like ring main units with automatic transfer schemes, enhancing selectivity and preventing unnecessary outages beyond the faulted section.

Innovation Point 2: High-Precision Measurement and Advanced Diagnostics. The relay acts as a high-accuracy metering device, continuously measuring and calculating phase/sequence currents, power (kW, kVAR), power factor, and energy. This data is accessible locally and remotely, eliminating the need for separate meters. Its comprehensive self-supervision and monitoring functions continuously check hardware health, software integrity, and the status of connected equipment (like circuit breaker wear based on trip counts), enabling a shift from schedule-based to condition-based maintenance.

Innovation Point 3: Seamless Integration and User-Friendly Interface. Despite its compact size, the AB121 is designed for easy integration into modern SCADA and control systems. With standard communication protocols like Modbus, it seamlessly connects to network control centers, providing real-time data and remote control capability. The intuitive local HMI with a clear menu structure and backlit display allows for easy on-site configuration, event log retrieval, and real-time data viewing, reducing dependency on specialized PC tools for basic operations.

Application Cases and Industry Value

Case Study: Enhancing Reliability in a University Campus Distribution Network.

A large university campus with a complex 11kV ring main distribution system experienced unexplained outages, affecting research labs and data centers. The existing electromechanical relays were slow, non-communicative, and difficult to coordinate.

Solution & Implementation: The protection system was upgraded with ALSTOM AB121 relays on all main and secondary feeders. Their identical time-current curves were precisely coordinated using software, ensuring the relay closest to a fault would operate first. The Modbus communication enabled integration into the campus’s existing energy management system.

Outcome and Value: Six months after commissioning, a fault occurred in an underground cable serving a dormitory. The corresponding AB121 relay cleared the fault in 60ms, isolating only that cable section. The rest of the campus, including the critical data center, remained energized. The relay instantly sent a detailed alarm with fault location and data to the control room. Maintenance crews were dispatched directly to the fault point, reducing outage time from hours to 45 minutes. The campus engineer credited the AB121 relays’ selectivity, speed, and communication for preventing a major campus-wide blackout and saving an estimated $250.000 in lost productivity and research data.

Related Product Combination Solutions

ALSTOM AG121/AG122 Arc Flash Detection Cards: Specialized modules that can be integrated with or used alongside the AB121 to provide ultra-fast light-based arc fault detection, significantly enhancing personnel and equipment safety in switchgear.

ALSTOM KCGG122 (or similar) Voltage/Transformer Protection Relay: Used in the same substation to protect the power transformer (differential, restricted earth fault), while the AB121 protects the downstream feeders, forming a complete bay protection scheme.

ALSTOM PSL (Distance Protection) & PCD (Differential Protection) Relays: For higher-voltage transmission lines or generator protection, working in coordination with feeder relays like the AB121 for a hierarchical, selective protection system.

Modbus RTU/ TCP Gateway or Communication Processor: A device that can aggregate data from multiple AB121 relays (using RS485) and convert it to Ethernet/IP or other protocols for integration into a modern DCS, SCADA, or plant-wide monitoring system.

Test Switches and Wiring Kits: Dedicated test plugs and disconnection blocks that allow safe secondary injection testing of the AB121 relay without disturbing the primary CT/VT circuits.

Micom S1 Agile (or similar) Relay Setting & Management Software: The dedicated PC software for configuring protection settings, retrieving event and disturbance records, and managing the firmware of the AB121 and other Micom relays.

Installation, Maintenance, and Full-Cycle Support

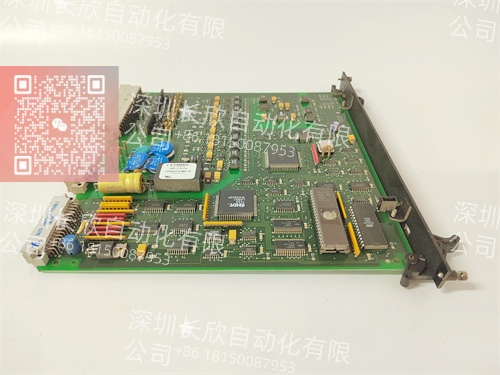

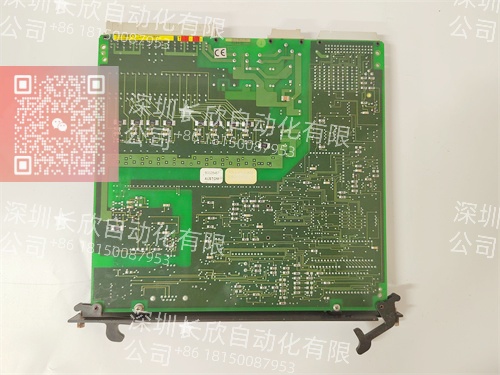

Installation: The ALSTOM AB121 is a panel-mounted device. It requires connection to Current Transformer (CT) and optionally Voltage Transformer (VT) secondary circuits for measurement, a reliable DC auxiliary supply for its electronics, and wiring to circuit breaker trip coils and binary signals. Correct CT polarity and ratio setting within the relay are critical. Initial configuration is done via the front HMI or, more efficiently, using dedicated setting software to upload the protection parameters, logic schemes, and communication maps.

Maintenance: Routine maintenance is minimal due to its solid-state design. Key activities include:

Annual Functional Test: Verifying trip outputs and binary inputs via secondary injection testing.

Setting Verification: Periodically checking that protection settings have not been altered and are still valid for the network configuration.

Event Log Review: Regularly downloading and analyzing stored fault and event records to assess system health and relay performance.

Visual Inspection: Checking for display alerts, abnormal status LEDs, and ensuring ventilation is not blocked.

Troubleshooting: The relay provides detailed self-diagnostics. Common issues include:

“CT Failure” or “VT Failure” Alarm: Check secondary wiring connections, fuses, and the health of the instrument transformers.

Communication Failure: Verify RS485 wiring polarity, termination resistors, baud rate, and station address settings.

Unexpected Trip: Analyze the detailed fault record (oscillography) stored in the relay to distinguish between a genuine system fault and an incorrect relay operation.

Full-Cycle Support: We provide comprehensive support for the ALSTOM AB121 and associated protection systems:

Technical Consultation: Assistance with relay selection, coordination studies, and scheme design.

Supply: Provision of genuine new or refurbished relays, spare parts, and accessories.

Configuration & Testing: Support with relay setting calculation, software configuration, and primary/secondary injection testing.

Training: On-site or classroom training on operation, maintenance, and testing of the relay.

After-Sales Support: Ongoing technical assistance, firmware updates, and repair services.

Contact us for expert protection engineering services, genuine ALSTOM/GE spare parts, and comprehensive support for your electrical network reliability.

Reviews

There are no reviews yet.