Product Overview

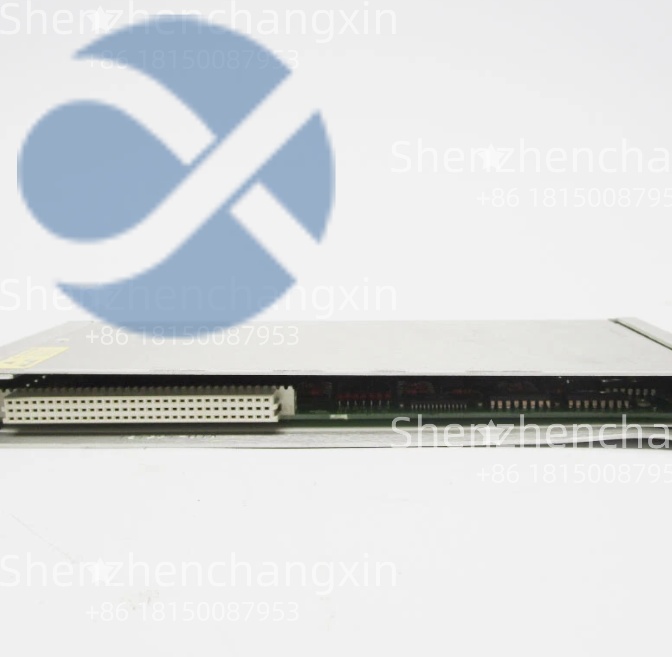

The Bently Nevada 125720-01 is a high-performance 4-channel relay output module designed for the Bently Nevada 3500 Series Machinery Protection System.Engineered to deliver precise control and reliable monitoring,this module serves as a critical component in industrial automation,enabling real-time fault detection and response in rotating machinery such as turbines,compressors,and pumps.The 125720-01 integrates seamlessly with the 3500 rack system,providing robust alarm and shutdown capabilities through its programmable relay outputs,ensuring operational safety and minimizing downtime.Its design emphasizes durability and precision,making it a cornerstone for industries prioritizing equipment reliability.

Built for demanding environments,the Bently Nevada 125720-01 supports advanced diagnostic functions,including programmable voting logic,which enhances decision-making for machinery protection.By facilitating rapid response to vibration anomalies,the 125720-01 helps prevent catastrophic failures,reducing maintenance costs and extending equipment lifespan.Its compatibility with Bently Nevada’s proprietary protocols ensures efficient data communication,making it a vital asset in integrated control systems.This module’s ability to operate in harsh conditions,coupled with its user-friendly configuration,positions it as an indispensable tool for achieving operational excellence in high-stakes industrial applications.

Technical Specifications

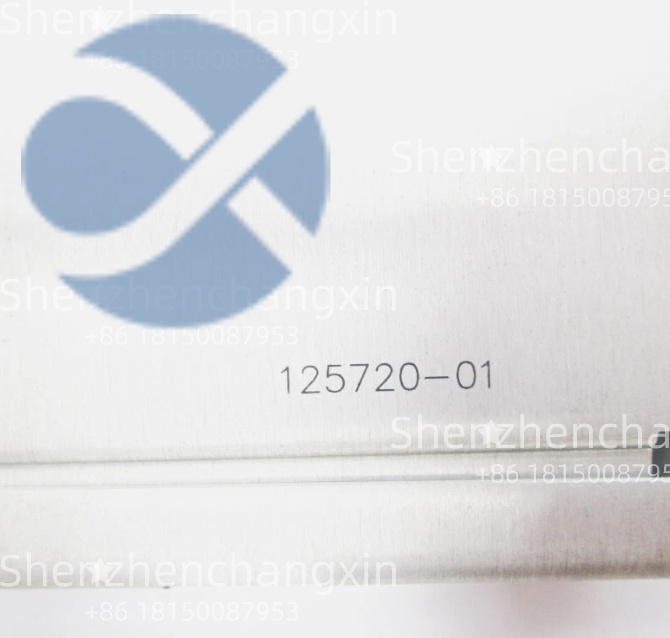

Product Model|125720-01

Manufacturer|Bently Nevada(GE)

Product Type|4-Channel Relay Output Module

Input Voltage|24 VDC nominal

Output Type|Relay(4 channels,dry contact)

Contact Rating|5 A at 250 VAC or 30 VDC

Communication Protocol|Bently Nevada 3500 proprietary

Operating Temperature|-30°C to+65°C

Physical Dimensions|241 mm x 24.4 mm x 99.1 mm

Weight|0.4 kg

Protective Rating|IP20

Mounting Type|3500 rack slot insertion

Main Features and Advantages

The Bently Nevada 125720-01 delivers unparalleled reliability through its 4-channel relay output design,enabling precise control over machinery protection systems.Each channel supports programmable voting logic,allowing customized alarm and shutdown configurations to match specific operational needs.This flexibility ensures rapid response to critical vibration events,preventing equipment damage and enhancing safety.

Robust design for harsh environments:Built to withstand extreme industrial conditions,the 125720-01 operates reliably from-30°C to+65°C,with a robust enclosure that resists dust and vibration per API 670 standards.Its galvanic isolation minimizes electrical noise,ensuring stable signal integrity in noisy environments like petrochemical plants.

Seamless integration:The 125720-01 integrates effortlessly with the 3500 rack system,supporting Bently Nevada’s proprietary communication protocols for real-time data exchange.Its compact design optimizes rack space,while LED indicators provide instant status feedback,simplifying diagnostics and reducing maintenance time.

High reliability and low maintenance:With a Mean Time Between Failures(MTBF)exceeding 100,000 hours,the 125720-01 ensures long-term performance with minimal upkeep.Its hot-swappable design allows replacement without system shutdown,boosting uptime by up to 30%in critical applications.This combination of durability,ease of use,and advanced functionality makes the 125720-01 a top choice for mission-critical automation systems.

Application Field

In the oil and gas industry,the Bently Nevada 125720-01 monitors vibration in compressors and turbines,triggering alarms or shutdowns to prevent catastrophic failures,ensuring compliance with stringent safety standards.Its precise relay outputs enable rapid response to anomalies,reducing the risk of costly downtime in offshore platforms or refineries.

Power generation plants rely on the 125720-01 to protect generators and auxiliary equipment,addressing issues like rotor imbalance or bearing wear.By integrating with the 3500 system,it provides real-time diagnostics,improving plant efficiency and extending equipment life by up to 20%.

In manufacturing,the 125720-01 supports high-speed machinery,such as CNC machines,by detecting vibration anomalies that could affect precision.Its programmable logic ensures tailored responses,minimizing production interruptions.Similarly,in chemical processing,the 125720-01 enhances safety by monitoring pumps and agitators,preventing leaks or failures in hazardous environments.Its versatility across industries underscores its role as a critical safeguard for operational reliability and efficiency.

Related Products

3500/32 125712-01:4-channel relay module,similar to 125720-01,with alternative firmware for specific applications.

3500/33 149986-01:16-channel relay module,expands capacity for larger systems compared to 125720-01.

3500/15 127610-01:Power supply module,provides stable power for 125720-01 in 3500 racks.

3500/22M 138607-01:Data interface module,enhances communication for 125720-01 in networked setups.

3500/42M 176449-02:Proximity monitor,pairs with 125720-01 for comprehensive vibration monitoring.

3500/94M 145988-01:Display module,visualizes data from 125720-01 for real-time monitoring.

3500/25 149369-01:Keyphasor module,complements 125720-01 for phase reference in rotating machinery.

Installation and Maintenance

Pre-installation preparation:Before installing the Bently Nevada 125720-01,ensure the 3500 rack is powered off and grounded to prevent electrostatic discharge.Verify a stable 24 VDC power supply with±10%tolerance.Check the rack slot for debris and secure the 125720-01 with proper alignment,ensuring a firm connection.Use shielded cables for relay outputs,adhering to Bently Nevada’s wiring guidelines to avoid signal interference.

Maintenance recommendations:Regular maintenance of the Bently Nevada 125720-01 involves quarterly visual inspections for dust or corrosion on connectors,using compressed air for cleaning.Test relay outputs annually with a multimeter to confirm contact integrity.Monitor LED indicators for fault alerts and update firmware as recommended to maintain compatibility.Store spare 125720-01 modules in a dry,ESD-safe environment to ensure readiness for hot-swap replacements,minimizing downtime.

Product Guarantee

Our company stands firmly behind the Bently Nevada 125720-01,delivering unmatched quality through rigorous factory testing to ensure zero defects.We offer comprehensive after-sales support,including 24/7 technical assistance and remote diagnostics to address any operational challenges swiftly.With a robust warranty covering material and workmanship,the 125720-01 guarantees long-term reliability in critical applications.Our expert-led training programs empower your team to leverage the module’s full capabilities,from configuration to maintenance.Partner with us for peace of mind,knowing the 125720-01 is backed by our commitment to excellence,ensuring your machinery protection systems perform at their peak with minimal risk

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.