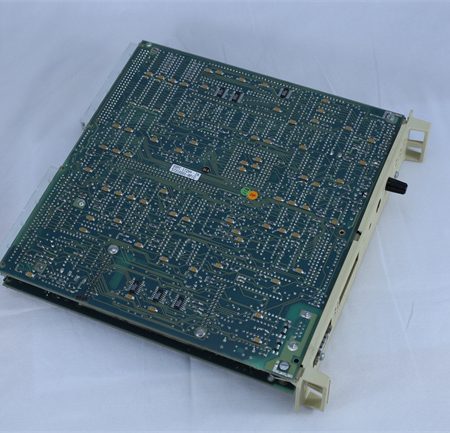

Description

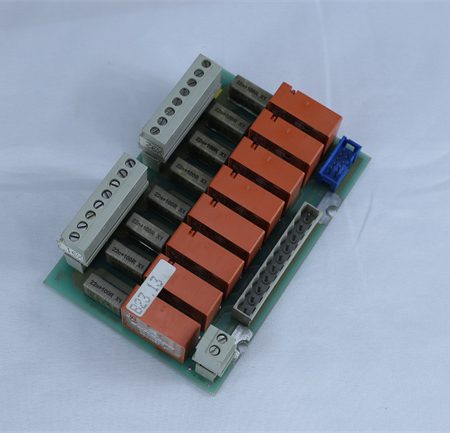

The BENTLY NEVADA 125840-02 is a high-reliability, 16-channel relay output module designed for the 3500 Machinery Protection System. It serves as the final control element interface between Bently Nevada’s monitoring logic (e.g., from 3500/42M, 3500/45. or 3500/53 modules) and external safety systems—such as turbine trip solenoids, emergency shutdown valves, motor starters, or DCS alarm panels. Each channel features dual Form-C (SPDT) electromechanical relays, rated for up to 2 A @ 30 VDC or 250 VAC, enabling both fail-safe de-energize and energize-to-trip configurations.

Engineered for mission-critical applications in oil & gas, power generation, and chemical processing, the 125840-02 combines high channel density with robust diagnostics, hot-swap capability, and compliance with functional safety standards—including IEC 61508 SIL 2 and API 670—making it a trusted component in Safety Instrumented Functions (SIFs) for rotating equipment.

Application Scenarios

At a U.S. Gulf Coast ethylene plant, a cracked steam cracker compressor required immediate isolation during overspeed events. Legacy relay panels suffered from contact welding and false trips due to EMI from nearby VFDs. After replacing them with BENTLY NEVADA 125840-02 modules integrated into a 3500/53 chassis, the system achieved:

Zero nuisance trips over 18 months

Built-in loop test validation during scheduled maintenance without process interruption

Remote relay status monitoring via Modbus TCP to the DCS

During an actual overspeed event (112% of rated speed), all 16 trip relays activated within 8 ms, successfully isolating lube oil pumps and closing anti-surge valves. The plant’s reliability manager noted: “The 125840-02 didn’t just execute a trip—it proved the entire SIF worked as designed.” This underscores its role as the dependable “last mile” of machinery protection.

Key Parameters

表格

Technical Principles and Innovative Values

Innovation Point 1: Dual Relays per Channel for Enhanced Safety Integrity

Each output uses two physically separate relays that can be wired in series (for higher voltage isolation) or parallel (for higher current)—or used independently for dual-purpose signaling (e.g., local alarm + remote DCS trip).

Innovation Point 2: Built-In Test Circuitry for Proof Testing

Supports partial stroke testing and loop validation without process interruption. Engineers can simulate alarm conditions and verify contact operation via Rack Configuration Software(RCS) or System 1. satisfying ISA-TR84.00.05 requirements.

Innovation Point 3: True Hot-Swap with State Preservation

When replaced live, the new module inherits the current alarm state from the controller—preventing unintended relay toggling during maintenance.

Innovation Point 4: Electromagnetic Hardening for VFD-Rich Environments

Features multi-stage filtering and shielded relay coils to reject noise from variable frequency drives, arc welders, and radio transmitters—common causes of false trips in legacy systems.

Application Cases and Industry Value

Offshore FPSO Gas Compression Train:

Six 125840-02 modules control 96 trip functions across three compressors. During a platform blackout, all relays operated correctly on backup UPS power—preventing a hydrocarbon release.

Nuclear Plant Main Turbine ETS:

Used in the Emergency Trip System (ETS) to de-energize stop valves. SIL 2 certification and redundant relay design met NRC regulatory expectations for single-failure criteria.

Mining SAG Mill Protection:

Replaced aging PLC-based relays; reduced cabinet footprint by 60% while improving mean time between failures (MTBF) from 24k to >100k hours.

Related Product Combination Solutions

3500/42M Monitor: Provides vibration-based alarm logic that triggers 125840-02 relays.

3500/45 Position Monitor: Sends thrust position alarms to 125840-02 for axial shift trips.

3500/53 Framework Interface: Required for advanced diagnostics and Modbus communication.

GE Mark VIe: In combined-cycle plants, 125840-02 relays often interface with turbine trip buses via dry contacts.

HIMA F60: In hybrid SIS, 125840-02 may serve as the final element driver under HIMA command.

Rockwell 1756-OW16I: Alternative solid-state output module—but lacks electromechanical isolation for safety-critical AC loads.

Bently Nevada System 1: Enables remote relay status viewing, test scheduling, and audit trail logging.

146039-XX Series Cables: Shielded I/O cables for reliable field wiring to marshalling panels.

Installation, Maintenance, and Full-Cycle Support

Installation requires secure seating in a powered 3500 chassis and proper field wiring using stranded, shielded cable with ferrules. Relay coils are driven by the backplane; no external power supply is needed. Wiring can include optional contact feedback loops to verify physical state—enhancing diagnostic coverage.

Maintenance includes:

Annual visual inspection of terminals

Semi-annual loop testing using built-in test mode

Relay life tracking (typical mechanical life: 100.000 operations)

We supply only genuine BENTLY NEVADA 125840-02 modules—new surplus or factory-refurbished—with full validation including:

Contact resistance measurement (<50 mΩ)

Coil activation/deactivation timing test

Dielectric withstand (1500 VAC for 1 min)

Thermal cycling (–30°C ↔ +70°C × 5 cycles)

Each unit includes original firmware, calibration record, and 12-month warranty. Our support team includes ex-Bently field engineers who provide free application reviews and SIL verification assistance.

Contact us for a customized solution—whether you’re designing a new machinery protection system or modernizing legacy relay panels, the BENTLY NEVADA 125840-02 delivers certified reliability, high density, and intelligent diagnostics where every millisecond counts.

Reviews

There are no reviews yet.