Description

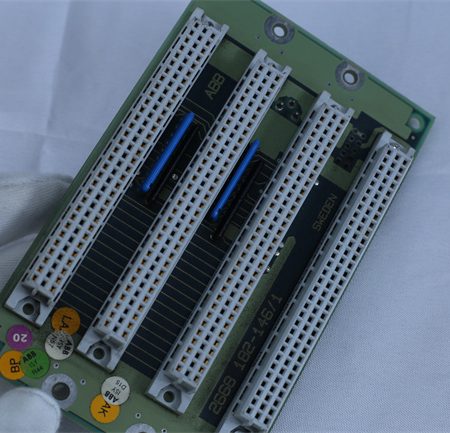

The BENTLY NEVADA 3500/15 Relay Module(part number 106M1079-01) is a dual-channel, high-integrity output interface designed for the 3500 Machinery Protection System. It converts alarm or trip signals from monitoring modules—such as the 3500/42M Vibration Monitor or 3500/45 Position Monitor—into isolated, electromechanical relay contacts capable of directly driving critical shutdown devices like solenoid valves, motor contactors, turbine trip relays, or DCS alarm panels.

Each channel features a Form-C (SPDT) relay, allowing flexible configuration for either de-energize-to-trip(fail-safe) or energize-to-trip logic. The module supports independent alarm mapping, built-in self-diagnostics, and on-demand loop testing—making it a key enabler of API 670 compliance and IEC 61508 SIL 2 safety functions in rotating equipment protection.

With its robust design and certification for hazardous areas, the 3500/15(106M1079-01) is widely deployed in oil & gas, power generation, petrochemical, and marine applications where reliability is non-negotiable.

Application Scenarios

At a Middle Eastern LNG liquefaction plant, a main refrigeration compressor experienced repeated nuisance trips due to degraded solid-state relays in an older protection system. Engineers replaced the legacy output cards with BENTLY NEVADA 3500/15(106M1079-01) modules, leveraging their electromechanical contacts and noise immunity. During commissioning, they used the built-in test mode to validate all trip paths without stopping the machine. Over the next two years, the system recorded zero false trips, even during nearby lightning strikes and VFD switching transients. When a genuine high-vibration event occurred (due to a cracked coupling), the 3500/15 activated the emergency shutdown valve within 7 ms, preventing catastrophic bearing failure. Plant personnel credited the module’s “bulletproof isolation and deterministic response” for avoiding a $ 15M incident.

Key Parameters

表格

Technical Principles and Innovative Values

Innovation Point 1: True Electromechanical Isolation

Unlike solid-state relays, the 3500/15 uses physical contacts that provide galvanic isolation—immune to voltage spikes, ground loops, and EMI from VFDs or arc welders.

Innovation Point 2: Flexible Trip Philosophy Support

Each channel can be independently wired for fail-safe(de-energize = trip) or energize-to-trip, accommodating diverse plant standards without hardware changes.

Innovation Point 3: Integrated Proof Test Capability

Using Rack Configuration Software(RCS) or System 1. operators can simulate alarm conditions and verify relay operation—fulfilling ISA-TR84.00.05 requirements for periodic functional testing without process interruption.

Innovation Point 4: Seamless 3500 Ecosystem Integration

Automatically inherits alarm logic from upstream monitors; no external wiring or logic solver needed—reducing engineering errors and validation effort.

Application Cases and Industry Value

Combined-Cycle Power Plant:

Used to trip gas turbine fuel valves on high axial vibration. SIL 2 compliance satisfied NERC CIP audit requirements for critical infrastructure protection.

Offshore Oil Platform:

Controls emergency shutdown of seawater injection pumps. ATEX certification allowed direct installation in Zone 2 hazardous areas.

Steel Mill Rolling Stand:

Replaced PLC-based relays; improved mean time between failures (MTBF) from 18k to >80k hours due to superior contact durability.

Related Product Combination Solutions

3500/42M: 4-channel vibration monitor that sends alarm signals to 3500/15 relays.

3500/45: Thrust position monitor for axial shift protection.

3500/32: 4-channel relay module (higher density alternative for non-SIL applications).

3500/53: Framework interface for Modbus communication and advanced diagnostics.

GE Mark VIe: In turbine plants, 3500/15 relays often interface with Mark VIe trip buses via dry contacts.

HIMA H51q: In hybrid SIS architectures, 3500/15 may serve as the final element driver under HIMA command.

Bently Nevada System 1: Enables remote relay status monitoring, test scheduling, and compliance reporting.

146039-XX Series Cables: Shielded I/O cables for reliable field termination to marshalling panels.

Installation, Maintenance, and Full-Cycle Support

Installation involves inserting the module into any available slot in a powered 3500 chassis and wiring field devices to the front-terminal block (screw-type, accepts 12–22 AWG). No external power is required—the relay coils are driven via the backplane.

Best practices:

Use shielded, twisted-pair cable with shield grounded at one end

Fuse external circuits per NEC/IEC standards

Enable “Test Mode” during commissioning to verify contact operation

Maintenance includes:

Annual visual inspection of terminals and contact wear

Semi-annual functional test using built-in diagnostics

Relay life tracking (typical mechanical life: 100.000 operations)

We supply only genuine BENTLY NEVADA 3500/15(106M1079-01)—new surplus or factory-refurbished—with full validation including:

Contact resistance (<50 mΩ)

Coil activation timing (<10 ms)

Dielectric strength (1500 VAC for 1 minute)

Thermal cycling (–30°C ↔ +70°C)

Each unit includes original firmware, calibration record, and 12-month warranty. Our team includes ex-Bently field engineers who provide free application reviews and SIL verification support.

Contact us for a customized solution—whether you’re protecting a single critical pump or integrating machinery protection into a global asset strategy, the BENTLY NEVADA 3500/15(106M1079-01) delivers certified reliability, flexibility, and peace of mind where failure is not an option.

-450x375.jpg)

Reviews

There are no reviews yet.