Application Scenarios

At a North Sea offshore platform, a main gas compressor train experienced delayed shutdowns during bearing overheating events due to slow response from legacy PLC-based alarm handling. After integrating the BENTLY NEVADA 3500/33-149986-01. each Danger-level vibration channel from the 3500/42M was directly mapped to a dedicated dry-contact relay that triggered the emergency shutdown valve within <100 ms. During a subsequent rotor instability event, the 3500/33-149986-01 activated its relays instantly, isolating the compressor before catastrophic failure. The platform’s reliability team credited the module with “closing the loop between detection and action”—turning predictive insights into life-saving mechanical responses.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Direct Alarm-to-Relay Mapping Without External Logic

The 3500/33-149986-01 eliminates dependency on DCS or PLC for trip execution. Each relay can be hard-mapped to a specific channel’s Alert or Danger state (e.g., “Turbine_Vib_X_Danger → Relay 5”), ensuring deterministic, sub-100 ms response—critical for API 670 compliance.

Innovation Point 2: Field-Verifiable Relay Functionality

Unlike sealed-output modules, the 3500/33-149986-01 includes front-panel test buttons that manually energize each relay—allowing technicians to validate wiring and contact operation without triggering actual alarms, streamlining commissioning and safety audits.

Innovation Point 3: Fail-Safe Design with Dual Power Redundancy

Powered by the 3500 backplane with optional dual 3500/15 supplies, the module defaults relays to safe state (de-energized) on power loss or internal fault—preventing false “healthy” signals during system failures.

Innovation Point 4: High-Density, Modular Flexibility

With 16 relays in a single-width module, the 3500/33-149986-01 reduces rack space and wiring complexity versus legacy 4- or 8-channel units—ideal for large turbines or multi-machine skids requiring dozens of discrete outputs.

Application Cases and Industry Value

In a U.S. petrochemical plant, a critical ethylene compressor suffered repeated bearing seizures because its old relay panel could not distinguish between Alert and Danger states—both triggered the same generic alarm. After installing the BENTLY NEVADA 3500/33-149986-01. engineers assigned separate relays: Alert activated a local beacon for early warning, while Danger directly tripped the lube oil dump valve and ESD system. Within one year, two incipient failures were caught during Alert phase, allowing planned shutdowns. The plant avoided an estimated $ 8M in potential damage and lost production. Maintenance supervisors now call the 3500/33-149986-01 their “electrical muscle”—converting diagnostic intelligence into decisive mechanical action.

Related Product Combination Solutions

BENTLY NEVADA 3500/42M: Vibration monitor—primary source of alarm signals routed to the 3500/33-149986-01 relays.

BENTLY NEVADA 3500/25: Keyphasor®/speed module—provides overspeed Danger alarms for direct turbine trip via 3500/33.

BENTLY NEVADA 3500/15-127610-01: Power supply—ensures reliable +24 VDC to the 3500/33 for fail-safe operation.

BENTLY NEVADA 3500/05: Communication interface—enables remote monitoring of relay status alongside analog data.

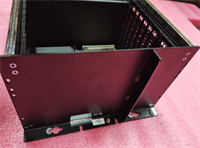

BENTLY NEVADA 1133 Chassis: High-density rack—supports multiple 3500/33-149986-01 modules for complex machinery trains.

BENTLY NEVADA 3500/44M: 4-channel relay module—used alongside the 3500/33 for specialized high-current or redundant trip paths.

BENTLY NEVADA Rack Configuration Software (RCS): Essential tool for mapping 3500 alarms to specific relays on the 3500/33-149986-01.

BENTLY NEVADA 3300 XL Probes: Sensor inputs whose fault conditions ultimately drive the 3500/33 relay actions.

Installation, Maintenance, and Full-Cycle Support

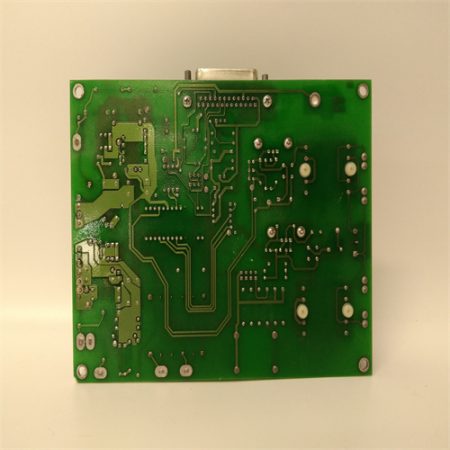

The BENTLY NEVADA 3500/33-149986-01 installs like any standard 3500 I/O module—simply slide into an available backplane slot and secure. Wiring involves connecting field devices (ESD valves, horns, DCS inputs) to the removable terminal blocks on the front—no internal jumpers or DIP switches. Configuration is performed in Rack Configuration Software (RCS), where users assign each relay to a specific channel and alarm type (Alert/Danger).

For maintenance, the 16 front-panel LEDs indicate real-time relay status (ON/OFF), while test buttons allow live verification of contact operation without system disruption. In redundant power setups, the module continues functioning even if one 3500/15 fails. Should replacement be needed, hot-swap capability (when enabled) allows removal without powering down the rack. We provide comprehensive support including relay contact life testing reports, SIL compliance documentation, and custom mapping templates for common turbine or compressor configurations. Every 3500/33-149986-01 undergoes functional validation of all 16 relays under load before shipment.

Contact us for a customized solution—whether you’re implementing a new API 670-compliant protection system, upgrading legacy relay panels, or enhancing shutdown reliability in hazardous areas, the BENTLY NEVADA 3500/33-149986-01 delivers unmatched speed, density, and confidence in your final layer of machinery defense.

-1.jpg)

Reviews

There are no reviews yet.