Application Scenarios

In a high-precision 5-axis machining center used for aerospace component manufacturing, the simultaneous and coordinated movement of the linear axes (X, Y, Z) and rotary axes (A, C) is critical for achieving complex contours and tight tolerances. Each of these axes is powered by a high-torque servo motor. The Bosch Rexroth VT-HNC100-1-23W-08-P-0 is the dedicated drive module controlling one of these critical axes, such as the high-thrust Z-axis responsible for the depth of cut. It takes precise position and velocity commands from the central CNC system via a high-speed digital link (e.g., SERCOS). The module then regulates high electrical current to the servo motor, ensuring it follows the commanded path exactly—accelerating, decelerating, and holding position against cutting forces with extreme stiffness. This precise control, managed by the VT-HNC100. directly translates to superior surface finish, dimensional accuracy of the machined part, and the ability to machine hard materials like titanium efficiently.

Parameter

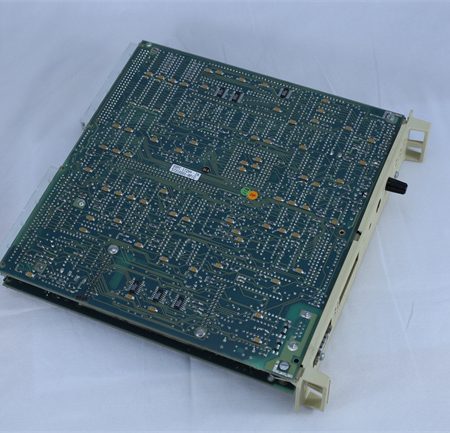

Annotation: The part number VT-HNC100-1-23W-08-P-0 is highly specific. VT-HNC100 is the base model. The suffix codes define the exact electrical characteristics, cooling method, and firmware. R900958999 is the unique order code for this exact configuration. It is crucial for sourcing the correct spare or replacement part.

Technical Principles and Innovative Values

The VT-HNC100-1-23W-08-P-0 is built on digital signal processing and real-time communication to achieve exceptional motion quality and system integration.

Innovation Point 1: High Dynamic Response and Precision through Advanced Control Loops. The drive module employs sophisticated, processor-based control algorithms for current (torque), speed, and position. It continuously compares the commanded value from the CNC with the actual feedback from the motor’s encoder, making corrections millions of times per second. This results in extremely high control loop bandwidth, allowing for very fast acceleration/deceleration, minimal following error, and excellent disturbance rejection (e.g., resisting variations in cutting force), which is paramount for high-speed, high-accuracy machining.

Innovation Point 2: Seamless System Integration via Open, Real-Time Networks. The module is equipped with a standard real-time industrial Ethernet interface like SERCOS III or PROFINET IRT. This allows it to be seamlessly integrated into a digital motion network. It enables synchronous, deterministic data exchange with the CNC controller and other drives, facilitating perfect multi-axis interpolation for complex contours. The “plug-and-produce” capability of this integration drastically reduces commissioning time and wiring complexity compared to analog pulse/direction systems.

Innovation Point 3: Condition Monitoring and Smart Diagnostics. Beyond basic control, the drive incorporates intelligent functions. It can monitor its own and the motor’s condition—tracking parameters like temperature, load profile, and vibration spectra. This data can be used for predictive maintenance, alerting operators to potential issues like bearing wear or mechanical misalignment before they cause a failure or produce scrap parts. This transforms the drive from a simple power amplifier into a source of valuable machine health data.

Application Cases and Industry Value

Case Study: Maximizing Uptime in a High-Volume Automotive Transmission Line

A manufacturer of automatic transmissions uses transfer lines with dozens of servo-driven axes for milling, drilling, and tapping operations. A failure of any axis drive causes a complete line stoppage, costing tens of thousands of dollars per hour. Their machines are equipped with Bosch Rexroth VT-HNC100 drives. The plant implemented a centralized condition monitoring system that taps into the drives’ built-in diagnostic data. One VT-HNC100-1-23W-08-P-0 controlling a critical feed axis began reporting a gradual increase in motor current during rapid traverses, even with no load. The system flagged this trend. Maintenance investigated during a planned break and found early signs of wear in the axis’s ball screw. The component was replaced proactively. The deep diagnostic capability of the drive prevented an unexpected failure that would have halted the line during production, safeguarding throughput and demonstrating a direct ROI through avoided downtime.

Case Study: Enabling Ultra-Precision in a Medical Device Laser Cutting Machine

A medical device company needed to cut intricate, micron-scale patterns into bio-compatible stent materials. The required precision was beyond the capability of standard servo systems. The machine builder selected a motion system centered on VT-HNC100 drives for their exceptional dynamic stiffness and smoothness. The drive’s high-resolution feedback processing and ultra-fast control loops eliminated the minute vibrations (“jitter”) that could degrade cut quality. The result was the ability to consistently produce stents with smoother edges and more precise geometries, which is critical for patient safety and device performance. The VT-HNC100’s performance became a key selling point for the machine builder, allowing them to command a premium in a specialized market.

Related Product Combination Solutions

Bosch Rexroth IndraMotion MTX CNC System: The high-level CNC controller that generates the complex motion trajectories and sends them to the VT-HNC100 drives over the real-time network.

Bosch Rexroth MSK or MKD Series Servo Motor: A high-performance synchronous servo motor perfectly matched to the VT-HNC100 drive in terms of power, torque, and feedback system (e.g., a motor with a HIPERFACE® DSL encoder).

Bosch Rexroth HCS01.1E-W0016: An example of a system power supply module that provides the regulated DC bus voltage for a cabinet containing multiple VT-HNC100 drive modules.

Bosch Rexroth SERCOS III Cables & Switches: The network infrastructure components used to create the deterministic real-time communication ring between the CNC, the VT-HNC100 drives, and other peripherals.

Bosch Rexroth IndraWorks: The comprehensive engineering software suite used to configure, parameterize, commission, and diagnose the entire system, including all VT-HNC100 drives.

Bosch Rexroth DKC/DKV/DKY Motor Power and Feedback Cables: The specific, shielded cables required to connect the VT-HNC100 drive to its servo motor, ensuring signal integrity and EMC compliance.

External Braking Resistor: A module often required to be connected to the VT-HNC100 to dissipate regenerative energy generated when the motor decelerates a high-inertia load.

Installation, Maintenance, and Full-Cycle Support

Installation of the VT-HNC100-1-23W-08-P-0 requires skilled personnel. It must be mounted on a properly rated and grounded heatsink or cooling plate, especially important for the “W” (liquid-cooled) version. Electrical connections must be made precisely: three-phase power input, DC bus link (if not internally connected), motor power (U/V/W), motor feedback, and the real-time network cable. Strict adherence to EMC guidelines—such as using shielded cables, proper grounding, and separation of power and signal lines—is non-negotiable to ensure stable operation. Commissioning is performed via the IndraWorks software, where the drive is configured, the motor data is entered, and the control loops are tuned.

Routine maintenance is primarily preventative and monitoring-based. Ensuring clean cooling systems (air filters, coolant quality/f low for liquid-cooled versions) is critical. The drive’s status and extensive diagnostic data should be monitored via the HMI or engineering software. The drive is not user-serviceable internally; if a fault is diagnosed as internal (e.g., power stage failure), the standard procedure is module replacement. Our full-cycle support for the VT-HNC100 includes providing detailed technical manuals and wiring diagrams, assisting with troubleshooting complex faults using diagnostic codes, supplying genuine replacement modules, and offering expert advice on system optimization and preventive maintenance strategies to maximize the lifespan and performance of your motion control system.

Ensure the precision and reliability of your critical motion axes with genuine, high-performance components. Contact us for technical documentation, compatibility verification, and support for your Bosch Rexroth VT-HNC100-1-23W-08-P-0 drive system.

Reviews

There are no reviews yet.