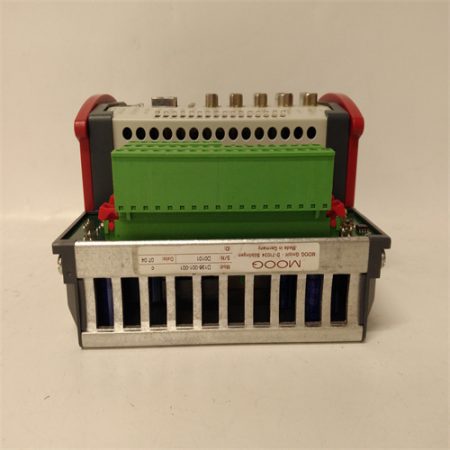

Main Features and Advantages

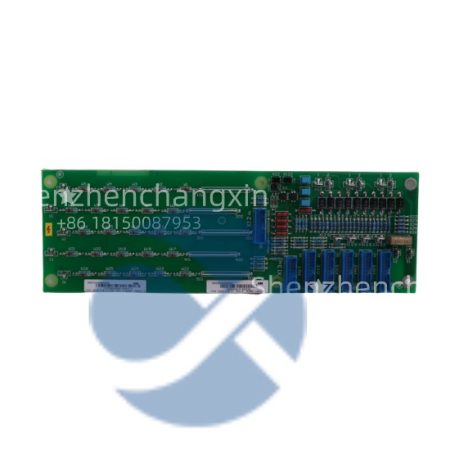

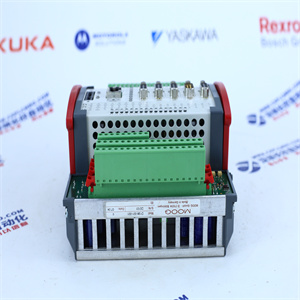

MOOG-Calibrated Signal Precision:The MOOG D136-001-007 is factory-calibrated to match MOOG’s motion control and hydraulic systems,delivering±0.1%accuracy for 4-20mA analog signals—far exceeding generic terminal modules(typically±0.5%accuracy).This precision is critical for applications like aerospace component testing,where MOOG’s test benches require exact load cell data to simulate flight conditions.The module’s signal latency of<1ms also ensures that position or pressure feedback reaches MOOG’s servo controllers in real time,preventing lag in hydraulic valve adjustments—essential for maintaining stability in high-speed industrial robots.Unlike third-party modules,it requires no additional calibration when paired with MOOG systems,saving technicians hours of setup time.

Rugged Design for Critical Environments:Built to MOOG’s strict industrial standards,the MOOG D136-001-007 withstands extreme temperatures(-40°C to+70°C)and electrical interference—making it ideal for offshore oil&gas,where hydraulic control systems operate in freezing,salt-laden air,or automotive factories with high electromagnetic noise from welding robots.Its gold-plated screw terminals reduce contact resistance,ensuring consistent signal transmission even in dusty or humid conditions(common in metalworking facilities).The module’s reverse polarity protection also prevents damage from incorrect wiring—a frequent cause of terminal module failures—reducing replacement costs and unplanned downtime.

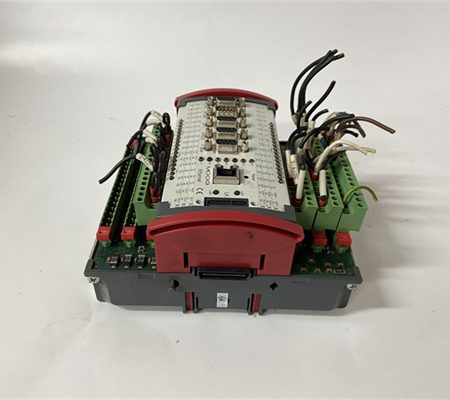

Seamless MOOG Ecosystem Integration:The MOOG D136-001-007 is designed to plug directly into MOOG’s G200/G300 servo drives and hydraulic control units,with pre-configured communication protocols that eliminate the need for custom programming.For example,when connected to a MOOG G300 servo drive in a robotic assembly line,the module auto-detects connected sensors(e.g.,linear position transducers)and syncs with the drive’s control software in seconds.This integration avoids compatibility issues common with mixing MOOG controllers and generic I/O modules,such as signal mismatch or communication drops.Technicians can also monitor the module’s status(channel health,signal strength)directly via MOOG’s Motion Control Center software,centralizing system diagnostics.

Hot-Swappable for Continuous Operation:The MOOG D136-001-007’s hot-swappable design is tailored to MOOG’s core markets,such as power generation(where hydraulic turbine control cannot be interrupted)or semiconductor manufacturing(where test bench downtime costs$10,000+per hour).If a channel fails,technicians can replace the module while the MOOG control system runs—thanks to the module’s built-in backup signal routing,which maintains data flow from other channels during replacement.Each channel also has a dedicated status LED(green for normal,red for fault),allowing quick identification of issues—e.g.,in a steel mill’s hydraulic roll control system,a red LED on Channel 3 would immediately alert technicians to a faulty pressure sensor signal,speedina faulty pressure sensor signal,speeding up troubleshooting.

Application Field

The MOOG D136-001-007 is a cornerstone in oil&gas hydraulic control,where it connects MOOG’s hydraulic valve controllers to field sensors in offshore platforms and onshore rigs.For example,on a deepwater oil rig,the module processes 4-20mA pressure signals from wellhead sensors and dry contact signals from hydraulic valve position switches,transmitting data to MOOG’s hydraulic control unit.Its-40°C to+70°C range withstands the platform’s extreme temperature swings,while surge protection resists interference from drilling machinery or lightning strikes.The module’s precision ensures the control unit adjusts hydraulic valve pressure in real time,preventing wellhead overpressure—a critical safety function in offshore operations.

In aerospace test and simulation,the MOOG D136-001-007 is integral to MOOG’s test benches for aircraft components(e.g.,wings,landing gear).It processes 4-20mA load cell signals(measuring stress during fatigue tests)and dry contact signals from test fixture clamps,ensuring MOOG’s motion controllers receive accurate data to replicate flight conditions.Its±0.1%signal accuracy is essential for meeting aerospace industry standards(e.g.,FAA requirements),where even minor measurement errors can invalidate test results.The module’s hot-swappable design also allows technicians to replace it during extended test runs(which can last weeks),avoiding costly test interruptions.

Automotive manufacturing relies on the MOOG D136-001-007 for robotic assembly lines and chassis test benches.In a car factory,it connects MOOG’s G300 servo drives(controlling robotic welders)to position sensors,ensuring the robots maintain 0.1mm precision in welding tasks.On MOOG’s chassis test benches,the module processes 4-20mA signals from force transducers,enabling the bench to simulate road vibrations and measure chassis durability.Its EMC compliance shields against noise from nearby welding robots or paint booths,ensuring stable signal transmission—critical for maintaining consistent production quality.

Finally,the MOOG D136-001-007 is used in power generation,particularly in hydraulic turbine control systems.It transmits 4-20mA speed signals from turbine sensors to MOOG’s control unit,which adjusts hydraulic governors to maintain 3,600 RPM(60Hz)for stable electricity output.Its hot-swappable design is vital here—replacing the module during maintenance requires no turbine shutdown,ensuring continuous power supply to the grid.The module’s channel-to-power isolation also protects against voltage spikes from the turbine’s electrical systems,reducing the risk of control system failures.

Related Products

MOOG D136-002-007:An 8-channel analog output terminal module,complementary to the MOOG D136-001-007 for sending 4-20mA control signals to MOOG hydraulic valves or servo motors.

MOOG 51304650-100:A redundant 24V DC power supply module,engineered to power the MOOG D136-001-007 and MOOG servo drives in mission-critical systems(e.g.,nuclear turbine control).

MOOG G300 Servo Drive:A high-performance motion controller that communicates directly with the MOOG D136-001-007 to process sensor data and control robotic or hydraulic systems.

MOOG D136-003-007:A 16-channel digital input terminal module,an alternative to the MOOG D136-001-007 for applications requiring more digital channels(e.g.,monitoring multiple test fixture statuses).

MOOG 623-4039 Hydraulic Valve:A precision hydraulic valve that receives control signals from the MOOG D136-002-007(paired with the MOOG D136-001-007)for oil&gas or power generation use.

MOOG Motion Control Center Software:A diagnostic tool that monitors the MOOG D136-001-007’s channel status,signal accuracy,and firmware version,enabling remote troubleshooting.

MOOG 133442-01 Position Sensor:A 4-20mA linear position transducer compatible with the MOOG D136-001-007,used in robotic arms and hydraulic cylinders to provide position feedback.

MOOG D136-004-007:A dual-channel isolated terminal module,upgraded from the MOOG D136-001-007 with 1kV channel-to-power isolation for high-voltage environments(e.g.,electric vehicle test benches).

MOOG Test Bench Automation Kit:A turnkey solution including the MOOG D136-001-007,G200 servo drive,and sensors,designed for quick deployment in aerospace or automotive component testing.

Installation and Maintenance

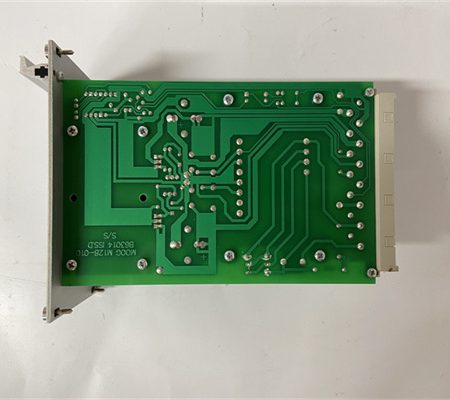

Pre-installation preparation:Before installing the MOOG D136-001-007,confirm compatibility with your MOOG control system(G200/G300 servo drives require firmware v5.0+to support hot-swapping).Test the 24V DC power supply with a calibrated multimeter to ensure voltage stays within 20.4V-27.6V—unstable power can degrade the module’s signal accuracy or damage internal components.Mount the module in a control cabinet or test bench rack away from heat sources(e.g.,MOOG servo drive heat sinks)and high-interference equipment(e.g.,welding inverters)to maintain the-40°C to+70°C operating range.Label each of the 8 I/O channels to match connected devices(e.g.,“Wellhead Pressure Sensor”or“Robotic Position Transducer”)using MOOG’s recommended labeling standards—this simplifies diagnostics via Motion Control Center software.Use 24AWG to 12AWG stranded wire(rated for industrial use)and strip wires to 6mm(0.24in)to ensure proper contact with the gold-plated screw terminals;avoid using solid wire,which can loosen under vibration.Finally,use MOOG’s Motion Control Center software to assign the module to your MOOG controller,configure channel types(analog/digital),and set signal ranges(e.g.,4-20mA for pressure sensors).

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.