Product Overview

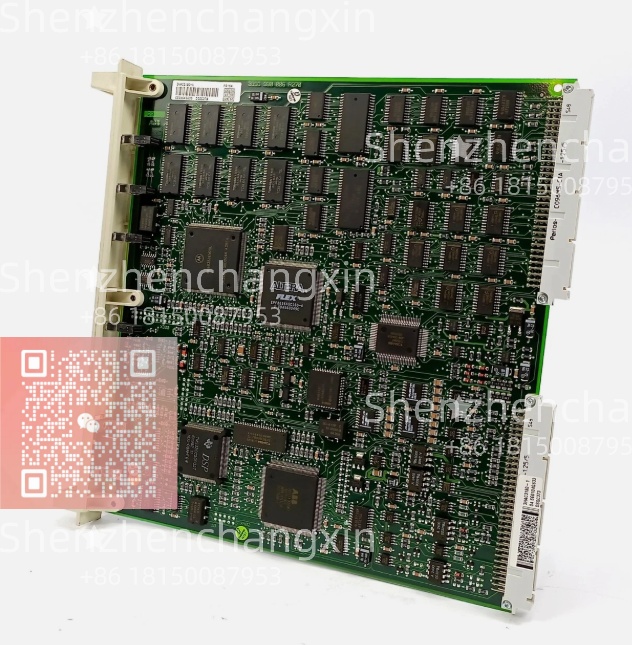

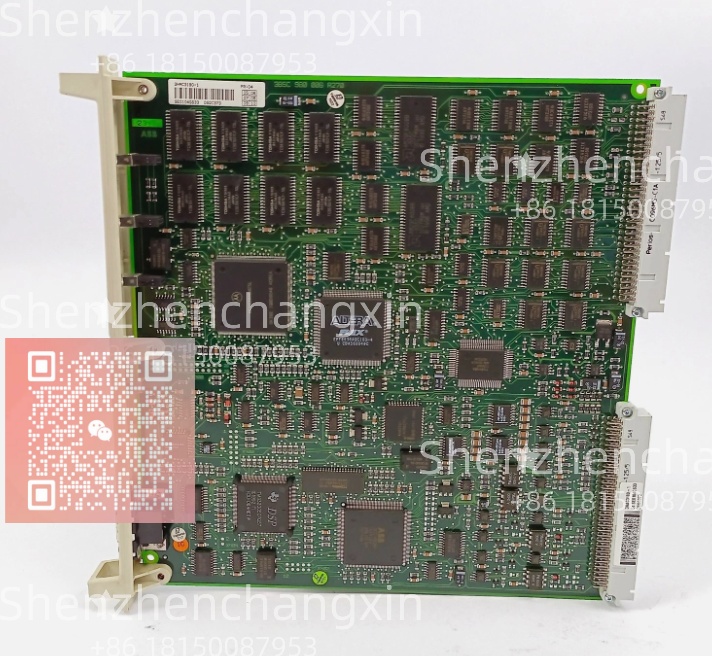

The ABB 3HAC3180-1(3BSC980006R270)DSQC 373 is a dedicated digital input/output(I/O)signal module designed for integration within ABB’s S4C Plus and S4 robot controller cabinets,serving as a critical interface between the robot’s control system and the external world.This ABB 3HAC3180-1 module is specifically engineered for use with ABB’s large industrial robot families,including the IRB 6600,IRB 6620,IRB 6640,and IRB 6650 series,where reliable and precise signal exchange is paramount for safe and efficient operation.As part of the DSQC(Digital Signal and Quick Connect)series,the 3HAC3180-1 facilitates the transmission of essential control,safety,and status signals that coordinate the robot’s movements with its surrounding machinery,such as conveyors,tooling,safety interlocks,and peripheral devices.

Functionally,the ABB 3HAC3180-1(3BSC980006R270)DSQC 373 acts as a signal conditioning and distribution hub.It receives digital commands from the robot controller and routes them to external actuators or indicators,while simultaneously collecting status signals from external sensors,safety gates,and machine states,and relaying this information back to the controller.This bidirectional communication is fundamental for implementing complex automation sequences,ensuring safety protocols are enforced,and enabling seamless integration of the robot into a larger production cell.The 3BSC980006R270 module is built to withstand the electrical noise and mechanical stresses found in industrial environments,providing a stable and dependable link in the automation chain.Its role in managing safety-related signals,such as emergency stop acknowledgments or safety gate monitoring,underscores its importance in maintaining a secure working environment around large robotic systems.

Technical Specifications

Product Model ABB 3HAC3180-1(3BSC980006R270)

Manufacturer ABB

Product Type Digital I/O Module

Series/Platform DSQC 373/S4C Plus/S4 Controller

Function Robot Controller I/O Interface

I/O Type Digital Input/Output

Number of Channels 8 Channels(Configurable as Input or Output)

Signal Voltage 24 V DC

Input Voltage Range 10-30 V DC

Output Type Relay or Solid-State(Typical for DSQC 373)

Output Current(per channel)Typically 0.5 A-2 A(Relay),Higher for Solid-State

Communication Interface Backplane Bus(DSQC Bus)

Power Supply+24 V DC(from Robot Controller Cabinet)

Operating Temperature 0°C to+45°C(Cabinet Ambient)

Storage Temperature-25°C to+55°C

Humidity 5%to 95%RH,non-condensing

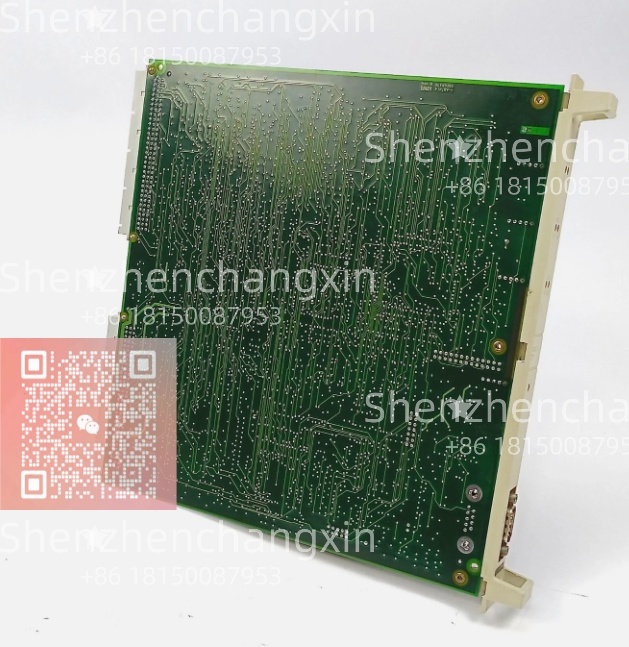

Mounting DIN Rail(within Robot Controller Cabinet)

Approvals CE,UL,cUL

Main Features and Advantages

The ABB 3HAC3180-1(3BSC980006R270)DSQC 373 offers several key advantages that make it indispensable for ABB robot integration.Its primary strength lies in its seamless compatibility with the S4C Plus and S4 controller platforms and specific ABB robot models,ensuring plug-and-play functionality and eliminating complex configuration hurdles.The module’s 8 configurable digital channels provide flexibility,allowing engineers to tailor the I/O setup to the specific needs of the application,whether it requires monitoring multiple sensor inputs or controlling various external devices.This configurability enhances the adaptability of the robot cell without requiring multiple specialized modules.

Another significant advantage is its robust design for industrial environments.The 3BSC980006R270 is engineered to operate reliably within the electrically noisy environment of a robot cabinet,featuring high immunity to electromagnetic interference(EMI).Its construction ensures long-term stability,minimizing the risk of signal errors that could lead to production downtime or safety incidents.The module plays a critical role in safety systems,often handling signals related to emergency stops,safety door interlocks,and mode selection,thereby directly contributing to the overall safety integrity of the robotic workcell.Furthermore,its standardized form factor and mounting system simplify installation,replacement,and maintenance within the controller cabinet.The clear labeling and established diagnostic procedures(often indicated by status LEDs)allow for rapid troubleshooting,reducing mean time to repair(MTTR)when issues arise.The ABB 3HAC3180-1 thus delivers a combination of reliability,flexibility,and safety that is essential for high-performance robotic automation.

Application Field

The ABB 3HAC3180-1(3BSC980006R270)DSQC 373 is predominantly found in manufacturing facilities utilizing large ABB industrial robots for demanding material handling,welding,and assembly tasks.In automotive production,it is a vital component in body shops and powertrain plants,where IRB 6600 series robots perform arc welding,spot welding,and heavy part transfer.The module manages signals for coordinating the robot’s movements with conveyor systems,controlling welding equipment(start/stop,gas flow),monitoring tooling status(e.g.,gripper open/close),and interfacing with safety systems like light curtains and access gates surrounding the robot cell.

In general industry,the 3BSC980006R270 supports applications such as machine tending,where robots load and unload CNC machines or presses.It handles signals to confirm machine readiness,initiate robot cycles,and receive completion signals.In palletizing and depalletizing operations,the ABB 3HAC3180-1 monitors pallet positions,conveyor status,and stack height sensors.Its role extends to any application requiring the robot to interact with external machinery or respond to environmental conditions.The module is particularly crucial in environments where safety is paramount,as it often processes signals from safety relays,enabling the robot to stop immediately if a safety perimeter is breached.By providing a reliable and standardized interface,the DSQC 373 module ensures that ABB robots can be effectively and safely integrated into complex,automated production lines across the automotive,aerospace,and heavy machinery sectors.

Related Products

ABB DSQC 380 is a related I/O module often used alongside the ABB 3HAC3180-1 for expanded I/O capacity or different signal types.ABB 3HAC022675-001 is a typical power supply unit for S4C Plus cabinets that powers the 3BSC980006R270.ABB M2000 CPU(e.g.,3HAC3180-1)is the main controller CPU for S4C Plus systems,which the DSQC 373 interfaces with via the backplane.ABB DSQC 651 or DSQC 652 are communication interface modules(e.g.,for DeviceNet or Profibus)that can coexist with the 3HAC3180-1 in the same cabinet.ABB 3HAC027865-001 is a common robot cable for IRB 6600 series,connecting the controller(and thus the 3BSC980006R270)to the robot arm.ABB DSQC 328 is another I/O module variant within the DSQC series for different I/O configurations.ABB S4C Plus Cabinet is the complete control enclosure that houses the ABB 3HAC3180-1 and other modules.ABB IRB 6600 is the primary robot model that utilizes controllers equipped with the 3BSC980006R270.ABB 3HAC033979-001 is a typical teach pendant used to program and operate the robot system linked to the ABB 3HAC3180-1.ABB DSQC 335B is a safety I/O module that may handle higher-level safety logic,potentially interfacing with signals managed by the DSQC 373.

Installation and Maintenance

Pre-installation preparation:Before installing the ABB 3HAC3180-1(3BSC980006R270)DSQC 373,ensure the robot controller cabinet is completely powered down and locked out to prevent electrical hazards.Verify that the cabinet’s DIN rail is clean and secure.Confirm that the backplane connectors are undamaged and free of debris.Gather the necessary tools,such as a screwdriver for securing the module and terminal blocks.Prepare the field wiring,ensuring the use of appropriate gauge wire(typically 0.34 to 1.5 mm²)and color-coding for inputs and outputs.Review the robot system’s electrical schematics to identify the correct terminal assignments on the 3BSC980006R270 for the specific signals being connected.

Maintenance recommendations:Regularly inspect the ABB 3HAC3180-1 for signs of overheating,physical damage,or loose connections.Check the tightness of terminal screws periodically,as vibration can cause them to loosen over time,leading to intermittent faults or arcing.Monitor the status LEDs on the front of the 3BSC980006R270 during normal operation;they should indicate correct power and signal states.If a channel fails,use a multimeter to verify the field wiring and the external device(sensor or actuator)before concluding the DSQC 373 module itself is faulty.The ABB 3HAC3180-1 is generally a robust and reliable component,but its performance depends on clean power and secure connections;therefore,include checks of the cabinet’s power supply and grounding in routine maintenance.Replacement is straightforward:power down the cabinet,unlatch the module,remove it from the DIN rail,install the new 3BSC980006R270,and re-terminate the wiring.

Product Guarantee

Every ABB 3HAC3180-1(3BSC980006R270)DSQC 373 provided is guaranteed to be an authentic ABB product,sourced through verified channels and subjected to thorough quality inspection to ensure it meets original equipment specifications.We stand firmly behind the performance and reliability of this critical robot control component,offering a comprehensive warranty that reflects our confidence in its industrial durability.Our commitment includes responsive technical support to assist with installation queries,troubleshooting guidance,and confirmation of compatibility with your specific robot system.Understanding that downtime in robotic automation is costly,we prioritize rapid fulfillment and accurate product delivery.The 3BSC980006R270 is more than just a spare part;it’s a vital link in your production chain,and we guarantee its readiness to ensure the continuous,safe,and efficient operation of your ABB robotic systems.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 / 3BHE031197R0001 / 3BHB030310R0001 In stock!!! Interested parties please contact us for negotiation

Reviews

There are no reviews yet.