Application Scenarios

In a critical steam turbine generator set, monitoring the radial vibration of the turbine shaft is paramount. Excessive vibration can lead to catastrophic mechanical failure. An 8mm eddy current sensor is installed near the shaft to detect its relative movement, but its raw signal is unsuitable for long-distance transmission and direct input to a control system. The EPRO PR937620 converter is mounted in a junction box nearby. It powers the sensor, conditions its signal, and outputs a robust 4-20 mA signal representing the vibration level. This signal is then transmitted to the plant’s Distributed Control System (DCS) for continuous monitoring. If vibration exceeds safe limits, the DCS can trigger an alarm or initiate an automated shutdown, preventing severe damage. This scenario underscores the converter’s role in enabling reliable, long-distance signal transmission and system integration for critical predictive maintenance and safety shutdowns.

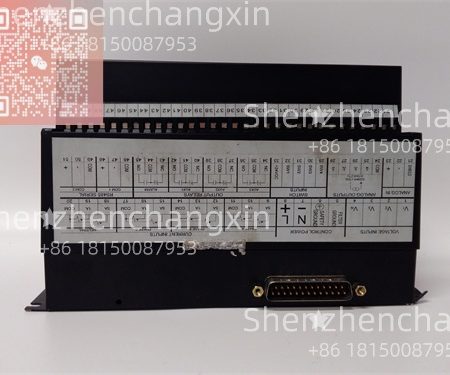

Parameter

Technical Principles and Innovative Values

The EPRO PR937620 operates based on the principles of eddy current sensing, acting as the intelligent interface between the sensitive probe and the industrial control world.

Innovation Point 1: High-Fidelity Signal Conditioning and Linearization. The raw signal from an eddy current probe is non-linear with respect to distance and is susceptible to cable length and temperature effects. The PR937620 contains sophisticated circuitry that linearizes this relationship, provides temperature compensation, and normalizes the output. This ensures that the final 4-20 mA signal is an accurate, linear representation of the actual gap or vibration, regardless of environmental conditions, which is critical for trustworthy measurements.

Innovation Point 2: Dual, Isolated Outputs for Redundancy and Flexibility. The module typically provides two completely isolated analog outputs (e.g., 4-20 mA and ±10V). This allows one output to be connected to a safety-critical system (like a turbine trip unit) and the other to the plant DCS for monitoring and trending. The isolation prevents ground loops and ensures that a fault in one system does not affect the other, enhancing overall system reliability and safety.

Innovation Point 3: Integral Sensor Power and Cable Drive. The PR937620 is not just a receiver; it provides the required high-frequency excitation current to the connected eddy current probe. It also incorporates circuitry to compensate for the capacitance and signal loss in the extension cable that runs from the converter to the probe. This “cable drive” capability allows for longer cable runs between the probe and the converter without signal degradation, offering greater installation flexibility in large machinery.

Innovation Point 4: Robust Design for Harsh Environments. Designed for industrial and power plant environments, the PR937620 typically features a rugged metal housing, secure screw terminals, and high immunity to electromagnetic interference (EMI). This ensures stable operation in electrically noisy environments near high-power motors and generators, where measurement integrity is paramount.

Application Cases and Industry Value

Case 1: Preventing Catastrophic Failure in a Centrifugal Compressor

A petrochemical plant’s large hydrogen recycle compressor began exhibiting increasing shaft vibration. The system, using an 8mm EPRO probe and a PR937620 converter, provided a continuous 4-20mA signal to the machinery monitoring system. The vibration trend, made reliable by the converter’s stable output, showed a gradual but steady increase. Based on this data, plant maintenance scheduled a shutdown two weeks in advance. During inspection, they found an imminent bearing failure. The maintenance superintendent stated that the early warning from the monitoring system, enabled by the reliable signal from the PR937620. prevented a forced outage and potential rotor damage exceeding $1 million, allowing for planned, lower-cost repairs.

Case 2: Optimizing Turbine Run-Time with Accurate Eccentricity Monitoring

In a combined-cycle power plant, accurate measurement of turbine shaft eccentricity (bowing) during slow-roll and startup is critical to avoid rubbing. The plant used PR937620 converters with 8mm probes for eccentricity measurement. The converter’s high resolution at very low frequencies (DC response) and stable ±10V output allowed the control system to precisely monitor the shaft’s “bowing” as it heated up. The control engineer reported that this reliable data gave operators the confidence to optimize the turbine’s startup curve, reducing startup time by 15 minutes per start. Over hundreds of starts per year, this translated to significant fuel savings and increased generation availability, demonstrating the converter’s role in operational efficiency, not just protection.

Related Product Combination Solutions

The EPRO PR937620 is a central component in a complete proximity measurement channel. It is always used as part of the following system:

Eddy Current Proximity Probe (8mm): The primary sensor (e.g., EPRO PR6423 series or compatible). It is installed close to the rotating shaft to generate the raw gap signal.

Extension Cable: A specially designed, low-noise coaxial cable (e.g., with TNC or other connectors) that connects the probe to the PR937620 converter. Its length is factored into the system calibration.

Power Supply: A stable 24V DC power supply unit to provide power to the PR937620 converter. In critical systems, this is often a redundant or uninterruptible power supply.

Monitoring System / DCS/PLC: The final destination for the converter’s output signals. This could be:

A dedicated machinery protection system (like EPRO MMS 6000 series).

A Distributed Control System (DCS) for plant-wide monitoring.

A Programmable Logic Controller (PLC) for safety interlocks.

Mounting Hardware & Junction Box: The PR937620 is typically rack-mounted in a protective junction box located as close as practical to the sensor to minimize cable run.

Oscilloscope or Calibrator (for setup/maintenance): Used during installation and calibration to verify the sensor gap and the converter’s output signal.

Installation, Maintenance, and Full-Cycle Support

Installation requires careful planning. The 8mm probe is first mounted in its holder with a precise gap to the shaft target. The probe is then connected via the extension cable to the PR937620 converter mounted in a nearby junction box. The converter is connected to the 24V DC supply, and its output wires are run to the monitoring system. The most critical step is calibration: using a micrometer or calibration fixture, the probe’s output is verified at known gaps, and the converter’s output (4-20mA) is scaled accordingly in the monitoring system software.

Maintenance is primarily preventive. It involves periodic verification of the system’s calibration during planned shutdowns by checking the “gap voltage” or output signal with a known target position. Regular inspection of cables and connectors for physical damage or corrosion is also important. The PR937620 itself is a solid-state device with no moving parts and requires no routine maintenance. If a fault is suspected, it can be bypassed with a calibrator to simulate a signal to the monitoring system, helping to isolate whether the issue lies with the probe, cable, or converter. We provide comprehensive support for the EPRO PR937620. including supply of genuine parts, detailed calibration procedures, and expert troubleshooting assistance to ensure the integrity of your critical machinery monitoring systems.

Contact us for reliable EPRO PR937620 signal converters and expert support to ensure the accuracy and availability of your vital machinery protection and condition monitoring channels.

Reviews

There are no reviews yet.