.jpg)

Application Scenarios

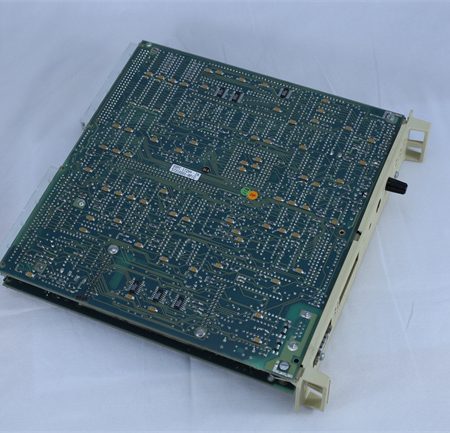

In a pharmaceutical bioreactor, precise temperature control is critical for cell culture viability. A bank of RTD (Resistance Temperature Detector) sensors, inserted at different depths in the vessel, provide millivolt-level signals representing temperature. The FOXBORO P0926KP module is the critical component that interprets these weak signals. Each RTD is wired to a dedicated, isolated channel on the P0926KP. The module provides the precise excitation current for the RTD, measures the resulting voltage drop, digitizes it with high accuracy, performs linearization based on the RTD’s characteristic curve, and transmits a clean, accurate temperature value to the DCS. This enables the control system to maintain the bioreactor at the exact setpoint. The module’s high channel-to-channel isolation prevents ground loops and noise from corrupting the sensitive measurements, directly solving the pain point of acquiring reliable, high-fidelity data from vulnerable low-level sensors in a noisy industrial environment.

Technical Principles and Innovative Values

Innovation Point 1: Universal, Software-Configurable Input Channels. Unlike modules dedicated to a single signal type, the P0926KP offers remarkable flexibility. Each of its four channels can be independently configured via the I/A Series engineering software to accept a wide variety of signals—RTDs (2. 3. or 4-wire), multiple thermocouple types, millivolts, or volts. This universal capability dramatically simplifies spares management (one module type covers many needs) and provides immense flexibility during system design, expansion, or sensor changes, as the hardware does not need to be replaced.

Innovation Point 2: High-Degree Isolation for Signal Integrity. The module incorporates premium isolation technology between each input channel and between all channels and the system bus. This is essential when measuring low-level signals (like microvolts from a thermocouple) in electrically noisy environments (e.g., near motor drives). The isolation blocks ground loops, rejects common-mode noise, and protects the sensitive DCS electronics from transient voltage spikes on the field wiring, ensuring the acquired data is accurate, stable, and reliable.

Innovation Point 3: Integrated Signal Conditioning and Diagnostics. The P0926KP is an intelligent signal conditioner, not just a simple digitizer. It provides the correct excitation current for RTDs, includes built-in cold-junction compensation (CJC) for thermocouples, and performs linearization for non-linear sensors like T/Cs. It also features continuous diagnostics, checking for sensor faults such as open circuits, short circuits, and out-of-range signals. This intelligence moves signal processing and validation to the I/O level, improving system performance and providing detailed health information for predictive maintenance.

Application Cases and Industry Value

Case 1: Glass Manufacturing Furnace Temperature Control. A float glass plant uses hundreds of thermocouples to monitor temperatures at precise zones within a massive, continuous furnace. They replaced old, dedicated temperature transmitters with Foxboro I/A Series cabinets equipped with P0926KP modules. The ability to mix J-type and K-type thermocouples on the same module provided layout flexibility. The high channel-to-channel isolation eliminated the intermittent signal noise that had plagued the old system, leading to more stable control. The maintenance team valued the detailed diagnostic alerts that immediately pinpointed failing thermocouples, allowing for proactive replacement during scheduled outages and preventing costly process upsets.

Case 2: Food & Beverage Batch Process Expansion. A dairy manufacturer needed to add temperature monitoring points for four new pasteurization holding tubes. The existing system used Foxboro I/A Series. Instead of installing separate transmitters for each 4-wire PT100 RTD, they installed a single P0926KP module. The module’s ability to directly interface with 4-wire RTDs provided the highest possible accuracy without external hardware. The software configuration was completed in minutes, and the new points were integrated seamlessly. The project engineer highlighted the 60% cost saving compared to using individual transmitters and the 80% reduction in cabinet space and wiring, showcasing the module’s efficiency for scalable projects.

Related Product Combination Solutions

The FOXBORO P0926KP is a key element within a complete I/O and control system:

Foxboro I/O Carrier/Chassis (e.g., FBM20x Enclosure): The physical housing that provides power, communication, and a slot for the P0926KP and other I/O modules.

Foxboro C300 Controller or other CP/FP Series: The control processor that executes logic, using the temperature data from the P0926KP for control and monitoring.

Foxboro FBM207 (4-20mA AI) / FBM232 (DO): Other I/O module types used alongside the P0926KP to handle different signal types (e.g., 4-20mA inputs, digital outputs).

Field Sensors: The various sensors connected to the module: RTDs (e.g., PT100), Thermocouples (Type J, K, etc.), millivolt output pressure sensors, etc.

I/A Series Engineering Software (I/A Workbench): The configuration tool where the P0926KP is defined, and each channel is configured for its specific sensor type, range, scaling, and alarm limits.

Field Wiring & Thermowells: The physical connection (using appropriate thermocouple/RTD wire) and the protective thermowell installed in the process for the temperature sensor.

Installation, Maintenance, and Full-Cycle Support

Installation involves mounting the module in its designated I/O carrier slot and connecting the field sensor wires to the correct terminals on its front connector block. Proper wiring practices are critical: using the correct wire type (e.g., shielded, twisted pair for T/Cs), ensuring correct polarity for T/Cs, and proper grounding/shielding. Configuration is entirely software-based via I/A Workbench, where the engineer selects the sensor type, wire configuration, engineering units, and alarm setpoints for each channel.

Maintenance is primarily condition-based. The module’s continuous diagnostics should be monitored via the DCS for any sensor faults. Periodic calibration verification of the measurement loop may be performed. The module itself is highly reliable. If a channel fails, the entire module is typically replaced as a unit. Hot-swap capability depends on the system’s redundancy configuration. Replacement is straightforward: power down the carrier (if needed), swap the module, and the configuration is automatically downloaded from the controller.

We provide comprehensive support for Foxboro I/A Series systems. This includes helping you verify the specific P0926KP hardware and firmware revision for compatibility with your system, supplying fully tested and warranted modules, and offering technical guidance on sensor wiring, configuration, and troubleshooting. Ensuring you have the correct, high-quality analog input module is key to maintaining the accuracy and reliability of your critical process measurements.

Accurately acquire your most sensitive process signals. Contact us for genuine Foxboro P0926KP modules and expert configuration support.

.jpg)

.jpg)

-450x375.jpg)

-450x375.jpg)

Reviews

There are no reviews yet.