Product Overview

FOXBORO E69F-BI2-MS is a high-performance,rugged current-to-pneumatic signal converter(I/P Converter)designed for industrial automation.In many factories,although the control system has been digitized(DCS or PLC),the final actuator,especially a large number of control valves,still adopts pneumatic drive.In this”electric-pneumatic”hybrid control scenario,E69F-BI2-MS plays a vital”bridge”role.

The core function of this converter is to achieve accurate conversion of electrical signals to pneumatic signals.It receives a standard 4-20mA DC current signal from a controller(such as a DCS or PLC)and converts it linearly into a corresponding pneumatic pressure signal,usually 3-15psi or 20-100kPa.This pneumatic signal is then sent to the diaphragm head of the pneumatic control valve,thereby accurately controlling the valve opening and then adjusting the process variable(such as flow,pressure,temperature or liquid level).

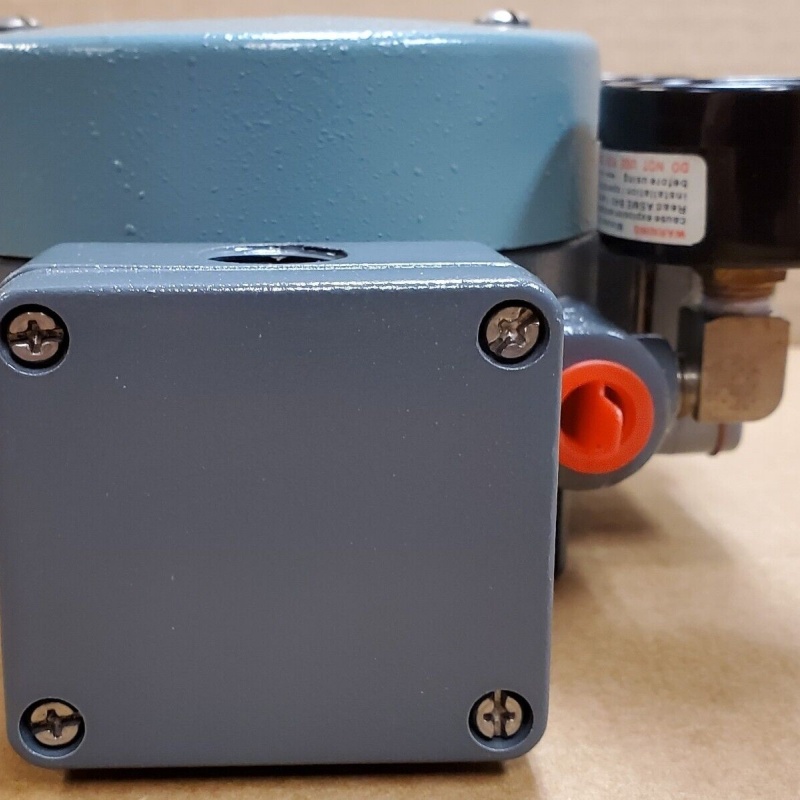

The design of E69F-BI2-MS reflects Foxboro’s professional accumulation in industrial field equipment.It is usually field-mounted and can be directly installed on the yoke of the control valve,on the pipe or on the panel,greatly simplifying wiring and installation.Its sturdy die-cast low-copper aluminum alloy housing is treated with epoxy powder coating,which makes it excellent in weatherproof and corrosion-resistant,meets the environmental protection requirements of IEC IP65 and NEMA Type 4,and can operate stably for a long time in harsh industrial environments.

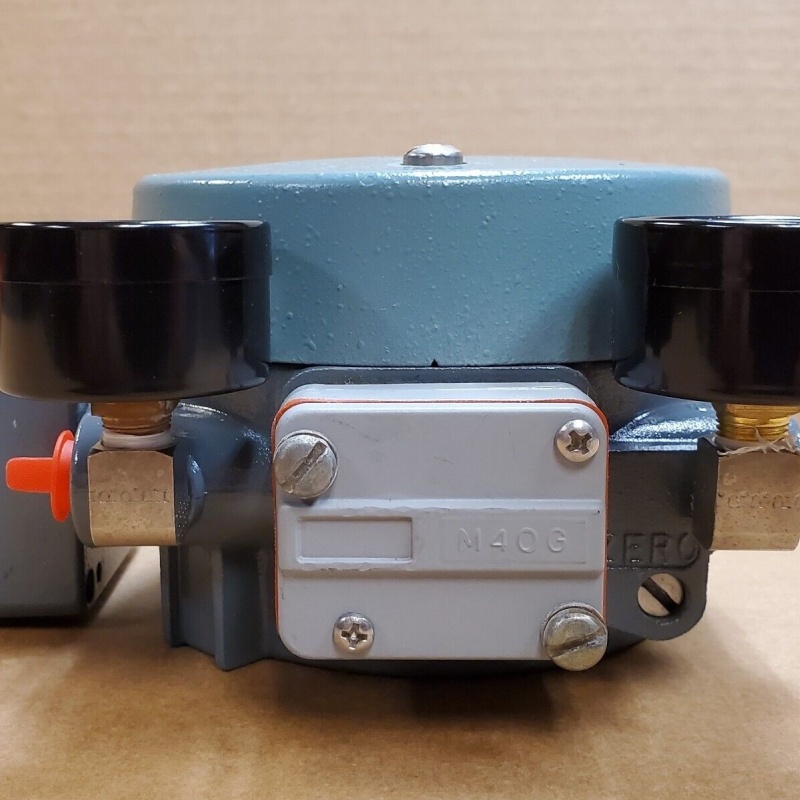

The”-MS”suffix in the model further enhances its convenience in field application:”M”stands for Miniature Junction Box,which is convenient for electrical connection;”S”stands for Supply/Output Gauges,which allows field personnel to directly observe the supply pressure and the output pressure of the converter without additional tools,facilitating quick diagnosis and debugging.

Although there are many new intelligent valve positioners with integrated I/P conversion functions on the market,the classic and time-tested independent I/P converter FOXBORO E69F-BI2-MS is still a reliable choice for many existing industrial devices and scenarios with specific requirements for cost and reliability,ensuring the accuracy and stability of the control loop.

Main Features and Advantages

As a classic current-to-pneumatic signal converter,FOXBORO E69F-BI2-MS has won wide recognition for its”unpretentious”but”hardcore”characteristics:

First,precise and reliable signal conversion is its core advantage.E69F-BI2-MS can convert standard 4-20mA electrical signals linearly and with high accuracy into 3-15psi(or 20-100kPa)pneumatic signals.This accuracy is essential for achieving precise control of process variables,ensuring that the control valve can open accurately according to the control system’s instructions,thereby improving control loop performance.

Second,the rugged industrial-grade design.The converter uses a die-cast low copper aluminum alloy enclosure and is epoxy powder coated,giving it excellent weatherproof and corrosion resistance capabilities.It meets industrial protection standards such as IEC IP65 and NEMA Type 4,and can operate stably in harsh field environments(such as high temperature,low temperature,humidity,dust or corrosive gas environment)for a long time,reducing failure rates and maintenance requirements.

Next,convenient field installation and maintenance.The E69F-BI2-MS is designed to be field-mounted and can be directly installed on the valve yoke,pipe or panel.The”-MS”option in the model is the icing on the cake:the”M”represents the Miniature Junction Box,which simplifies the electrical wiring and provides good protection;the”S”represents the Supply/Output Gauges,which allows field personnel to directly observe the gas source pressure and output pressure,and can perform preliminary diagnosis and debugging without additional tools,greatly improving work efficiency.

In addition,low air consumption.As a pneumatic device,air consumption is an important indicator to consider its operating cost.The E69F-BI2-MS is optimized in design,and its air consumption is relatively low,which helps to reduce operating costs and save energy,which is especially important for large industrial devices.

Finally,broad application compatibility.With its standard input/output signal range and multiple installation options,the E69F-BI2-MS can work seamlessly with all kinds of DCS,PLC,pneumatic control valves,and pneumatic actuators.Whether in new projects or retrofitting old systems,it can provide a reliable interface to ensure that electrical control signals can effectively drive pneumatic final control elements.

Application Field

As a professional current-to-pneumatic signal converter,the application field of FOXBORO E69F-BI2-MS is mainly concentrated in various industrial production sites where pneumatic actuators are still widely used:

First,in the oil,gas and petrochemical industries,E69F-BI2-MS plays a key role.In refineries,chemical plants and natural gas processing plants,a large number of control valves,cut-off valves,etc.are pneumatically driven.E69F-BI2-MS converts electrical signals from DCS or PLC into pneumatic signals,precisely controls various complex processes such as temperature,pressure,flow,liquid level,etc.,and ensures safe,efficient,and stable production.

Secondly,in the power industry,including thermal power plants and some industrial boiler systems,E69F-BI2-MS is also widely used.It converts electrical signals from boiler control systems(BMS)or DCS into pneumatic signals,which are used to precisely adjust fuel valves,water supply valves,dampers,etc.to control the combustion efficiency,steam pressure and flow of the boiler,and ensure the continuity and economy of the power generation process.

In the metallurgical industry,such as heating furnaces,blast furnaces and various auxiliary equipment in steel plants,some pneumatic actuators need to receive electrical control signals through I/P converters.In these harsh environments such as high temperature,dust,and vibration,the E69F-BI2-MS can still provide stable and reliable signal conversion to ensure smooth operation of the production line.

In addition,the E69F-BI2-MS also has its place in industries that have high requirements for process control accuracy,such as water/wastewater treatment,pharmaceuticals,food and beverage,and papermaking.It converts the instructions from the central control room into pneumatic signals to control pneumatic control valves in dosing systems,filtration systems,mixing containers,drying equipment,etc.,to achieve precise liquid/gas flow control and accurate adjustment of process parameters.

In short,the FOXBORO E69F-BI2-MS is an ideal choice for any industrial process that requires effective connection of modern electrical control signals with traditional pneumatic actuators.With its high precision and high reliability,it has become an indispensable”electric-pneumatic”conversion bridge in industrial automation.

Related Products

If you are interested in current-pneumatic signal converters such as FOXBORO E69F-BI2-MS,or your Foxboro system needs other related field devices,you can also pay attention to some common related products below:

Other models of the FOXBORO E69F series:such as E69F-BI2(no MS option),E69F-BH2(10-50mA input),these are I/P converters in the same series but may have slightly different configurations.

FOXBORO pneumatic control valve/actuator:The main function of E69F-BI2-MS is to drive these pneumatic devices.Knowing the corresponding valve model(such as Foxboro N series,Y series valve)can better understand its application.

FOXBORO pneumatic positioner:In some applications,the I/P converter may be used in conjunction with a pneumatic valve positioner to achieve more precise valve opening control.

FOXBORO I/A Series or Foxboro Evo™DCS system modules:These are upper control systems that generate 4-20mA output signals,such as FBM202(analog output module)or FCP270(field control processor),which are”upstream”devices of I/P converters.

Other brands of I/P converters:For example,Fisher/Emerson DVC series valve positioners(usually integrated with I/P functions),Masoneilan,Siemens and other brands also have similar current-to-pneumatic conversion products.

Field pressure gauge and filter pressure reducing valve:In order to ensure the normal operation and extend the life of the I/P converter,it is usually necessary to install an air filter pressure reducing valve and an output pressure gauge.

Installation and Maintenance

Installation preparation:Brother,installing a current-to-pneumatic converter like FOXBORO E69F-BI2-MS is a delicate job,and you have to”step by step”!First of all,it must be operated by a professional who has been officially certified by Foxboro or has experience in industrial instrument installation.Before any installation or maintenance,please strictly follow the safety regulations on site,confirm that the electrical power and gas source of the relevant circuits have been completely disconnected,and perform strict electrical inspection confirmation and lockout/tagout(LOTO)procedures.This is the first principle to ensure personal safety and prevent equipment damage!

Carefully read the official hardware manual included with the FOXBORO E69F-BI2-MS to understand its electrical wiring terminals(4-20mA input)and pneumatic interfaces(air supply,output).Choose a suitable installation location to ensure that the converter is firmly mounted on the valve yoke,pipe or bracket to avoid vibration and mechanical stress.Be sure to use high-quality shielded cables for electrical connections and ensure that the shielding layer is reliably grounded.When connecting the gas source,it is recommended to install an air filter pressure reducing valve upstream of the converter to ensure a clean,dry,and stable instrument air source(usually 20 psi or 35 psi).All pneumatic pipeline connections must be well sealed and leak-free.

Maintenance recommendations:Proper routine maintenance and monitoring of the FOXBORO E69F-BI2-MS is key to ensuring its long-term stable and accurate operation:

Regular visual inspection and cleaning:Check the E69F-BI2-MS housing regularly(such as quarterly or semi-annual)for physical damage,corrosion,or signs of water ingress.Remove dust and dirt from the surface.Check that all electrical and pneumatic connections are secure and not loose or leaking.

Air supply quality check:Make sure that the instrument air supply provided to the converter is clean,dry,and stable pressure(Clean,Dry,and Stable Pressure).Regularly check the air filter for water accumulation or contamination,and drain or replace the filter element if necessary.Unclean air supply is a common cause of I/P converter failure.

Functional inspection and calibration:If the E69F-BI2-MS is equipped with a pressure gauge,regularly observe its supply and output pressures to see if they are normal.If needed,a simple manual test can be performed:input a known current signal(such as 4mA and 20mA)to the converter,and then use a standard pressure gauge to measure whether its output pressure corresponds to 3psi and 15psi.If deviations are found,zero and span calibration may be required.Calibration usually involves internal screws or adjustment mechanisms,and it is recommended that professionals perform it according to the manual.

Monitor valve action:Observe whether the control valve driven by the E69F-BI2-MS moves smoothly and responds promptly.Abnormal valve jitter,slow response or failure to reach the set position may be a sign of degraded I/P converter performance.

Spare parts management:For critical circuits,it is recommended to keep a well-tested and compatible configuration.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB

Reviews

There are no reviews yet.