Application Scenarios

In a power plant’s boiler control system, dozens of thermocouples measuring critical temperatures are spread across the turbine hall. The fragile, low-voltage signals from these sensors are susceptible to electrical noise from motors and high-current cables over long wire runs. Directly connecting them to the control system’s analog input cards risks corrupted readings. The FOXBORO P0916AA serves as a vital interface panel installed in a marshalling cabinet close to the field. Each thermocouple wire lands on a terminal of the P0916AA. This unit provides signal conditioning, such as cold-junction compensation for thermocouples, and may include isolation and filtering to clean the signal. It then outputs a robust, standardized signal to the corresponding Foxboro FBM analog input module (e.g., an FBM214). It solves the critical pain point of protecting sensitive control system hardware from harsh field conditions and ensuring the integrity of measurement signals.

Technical Principles and Innovative Values

Innovation Point 1: Signal Integrity and System Protection. The core innovation of components like the P0916AA lies in their role as a protective buffer. They condition raw field signals (which can be noisy, grounded, or carry transients) into clean, safe signals compatible with the sensitive electronics of the FBM. By providing electrical isolation, they prevent ground loops and high-voltage surges from damaging the central control system, dramatically improving overall system reliability and mean time between failures (MTBF).

Innovation Point 2: Modularity and Simplified Maintenance. This component exemplifies the modular design philosophy of the I/A Series. It allows for the physical and electrical separation of field wiring from the system electronics. If a field circuit is damaged (e.g., a short circuit), the fault is typically contained within the termination panel, protecting the more expensive and complex FBM card. This makes troubleshooting and repair faster and easier, as field technicians can work on the termination panel without disturbing the control system backplane.

Innovation Point 3: Flexibility in Signal Handling. While specific to its designed signal type, such a component standardizes the interface. It allows a single type of FBM (which reads a standard signal like 1-5V) to connect to a variety of field devices (like different thermocouple types J, K, T, etc.) through the appropriate matching termination panel. This provides significant flexibility in system design and simplifies spare parts management.

Application Cases and Industry Value

Case 1: Petrochemical Plant Burner Management System. A refinery’s fired heater control uses dozens of flame scanners and fuel valve position feedback signals. These critical safety signals are connected via the P0916AA termination assemblies to redundant Foxboro FBMs. The termination panels provided intrinsic safety barriers for hazardous area signals and ensured clean digital inputs for the logic solver. During a plant turnaround, technicians needed to troubleshoot a faulty flame scanner circuit. Because of the modular design, they were able to safely disconnect and test the field wiring at the P0916AA terminals without shutting down the entire FBM or affecting other burner controls. This minimized downtime and showcased the value of clear interface points for maintenance.

Case 2: Pharmaceutical Batch Fermentation Control. A biotech facility uses RTDs for precise temperature control in fermentation vessels. The sensitive 3-wire RTD signals were routed to P0916AA termination panels configured for RTD input. These panels provided the excitation current, 3-wire lead compensation, and filtering necessary for accurate measurement. This setup ensured the Foxboro DCS received ultra-stable temperature readings, crucial for reproducible batch quality. The engineer credited the clean signal conditioning at the termination point for eliminating previous measurement drift issues, directly contributing to improved process consistency.

Related Product Combination Solutions

The FOXBORO P0916AA is never used in isolation; it is part of a complete signal chain:

Foxboro Fieldbus Module (FBM): The core I/O card that interfaces with the control network. The P0916AA connects directly to a specific FBM type (e.g., FBM214 for analog input, FBM217 for analog output, FBM222 for digital input).

Foxboro FBM Carrier/Enclosure: The chassis that holds the FBM and its associated termination units.

Field Devices: Sensors (e.g., Rosemount pressure transmitters, thermocouples) and actuators (e.g., Fisher control valve positioners) that connect to the field side of the P0916AA.

System Cable/Harness: The pre-fabricated cable that connects the P0916AA terminal block to the mating connector on the FBM card.

Foxboro C300 Controller or other CP: The control processor that reads from/writes to the FBMs.

I/A Series Software (I/A Workbench): Used to configure the I/O channel types and scaling parameters for the signals passing through the P0916AA and its associated FBM.

Installation, Maintenance, and Full-Cycle Support

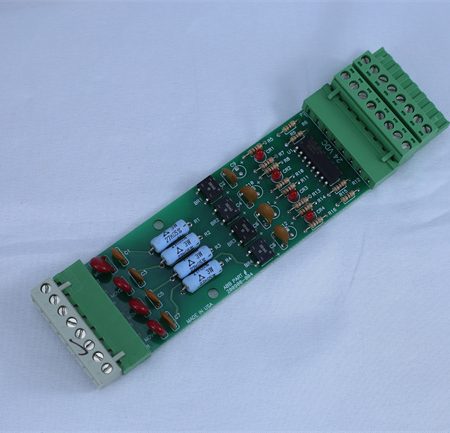

Installation involves mounting the P0916AA unit in its designated slot within the I/O assembly, adjacent to its corresponding FBM. Field wiring is landed on one set of terminals, and the system cable from the FBM is connected to the other. Correct wiring per the loop diagram and proper tightening of terminals are critical. Configuration is primarily done in software for the FBM, though the P0916AA itself may have jumpers or switches to configure signal type (e.g., current vs. voltage) or sensor type (e.g., TC type), which must be set manually.

Maintenance is primarily reactive or based on diagnostics from the control system. The P0916AA itself is a passive device with no active diagnostics. If a signal fault occurs, technicians use it as the test point to isolate whether the problem is in the field device/field wiring (upstream of the panel) or the system side (downstream to the FBM). Visual inspection for loose terminals or corrosion is also part of routine checks. If a channel on the P0916AA is damaged, the entire unit or the specific terminal block can often be replaced.

We provide expert support for Foxboro I/A Series systems. We can help you confirm the exact function and compatibility of the P0916AA with your specific FBMs, provide wiring diagrams, and supply genuine, factory-compatible termination hardware. Our goal is to ensure your signal interfaces are reliable and maintain the integrity of your control loops.

Need to confirm the specs or source this Foxboro interface component? Contact us for expert identification, genuine parts, and integration support for your I/A Series system.

-450x375.jpg)

Reviews

There are no reviews yet.