Application Scenarios

At a combined-cycle power plant in Texas undergoing a Mark VI to Mark VIe migration, engineers needed to replace aging analog contact interfaces that suffered from false trips during lightning storms. By installing new GE 1TGE120021R0610 modules across all turbine auxiliary systems—including lube oil pressure switches, bearing vibration alarms, and exhaust damper feedback—the facility achieved zero nuisance shutdowns over 14 months of operation, even during severe thunderstorms with nearby strikes. The robust optical isolation and common-mode rejection of the GE 1TGE120021R0610 proved decisive in stabilizing the protection logic, directly enhancing plant availability and dispatch reliability.

Technical Principles and Innovative Values

Innovation Point 1: True Redundant I/O Architecture with Dual Network Paths

The GE 1TGE120021R0610 connects simultaneously to two independent Mark VIe controller racks via separate Ethernet links. If one network fails, data continues flowing seamlessly—ensuring no loss of critical turbine status signals during partial system faults.

Innovation Point 2: Intelligent Diagnostics Reduce Mean Time to Repair (MTTR)

Each input channel on the GE 1TGE120021R0610 monitors for open circuits, short circuits, and marginal voltage levels. Faults are logged in real time and displayed in GE’s ControlST engineering workstation, cutting troubleshooting from hours to minutes.

Innovation Point 3: Hot-Swappable Design Enables Live Maintenance

Technicians can replace a failed GE 1TGE120021R0610 without powering down the I/O chassis or interrupting turbine operation—critical for plants running under NERC reliability standards requiring continuous monitoring.

Innovation Point 4: Optimized for Cyber-Secure Industrial Networks

As part of the Mark VIe ecosystem, the GE 1TGE120021R0610 supports secure firmware updates and role-based access control, aligning with NERC CIP and ISO/IEC 27001 requirements for critical infrastructure.

Application Cases and Industry Value

During a brownfield upgrade at a European waste-to-energy plant, the facility replaced obsolete PLC-based boiler interlocks with a full Mark VIe safety system centered on GE 1TGE120021R0610 input modules. Within six months, unplanned outages dropped by 72%, primarily due to the elimination of “ghost” signals caused by electromagnetic coupling from nearby motor starters. Operators now receive precise, timestamped event logs for every discrete input change—enabling root-cause analysis that previously required oscilloscope teams.

In another case, an LNG export terminal in Australia standardized its spare parts inventory around the GE 1TGE120021R0610 across three gas turbine-driven compressors. The module’s universal 24 V DC compatibility and plug-compatible form factor reduced spares count by 60% while improving cross-unit maintainability—demonstrating how standardization drives operational efficiency in remote locations.

Related Product Combination Solutions

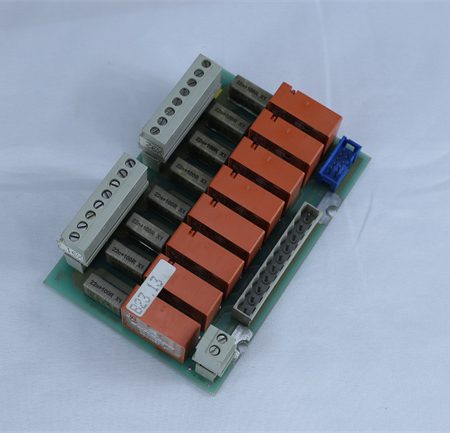

GE 1TGE120001R0101: I/O carrier base that houses the GE 1TGE120021R0610 and provides backplane power and communication.

GE IC695CPU320: While not Mark VIe, this PACSystems CPU illustrates GE’s broader I/O philosophy—useful for hybrid plant retrofits.

GE 1TGE120031R0610: 32-channel digital output module—complements the GE 1TGE120021R0610 for full loop control.

GE Mark VIe Controller (e.g., 1TGE100001R0001): Central processing unit that polls data from the GE 1TGE120021R0610 in real time.

GE ControlST Workstation: Engineering software used to configure, monitor, and diagnose the GE 1TGE120021R0610.

ABB 800xA with GE I/O Gateway: Integration solution allowing GE 1TGE120021R0610 data to appear in ABB’s unified automation environment.

HIMA H51q-F: Safety PLC that can cross-check critical signals from the GE 1TGE120021R0610 in high-integrity applications.

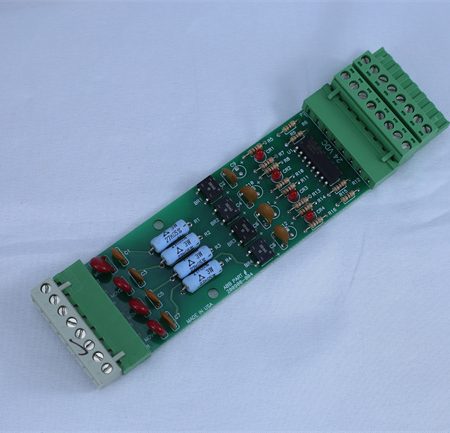

Phoenix Contact IB IL 24 DI 32/HD: Third-party alternative for non-safety I/O—useful for cost-optimized auxiliary systems.

Installation, Maintenance, and Full-Cycle Support

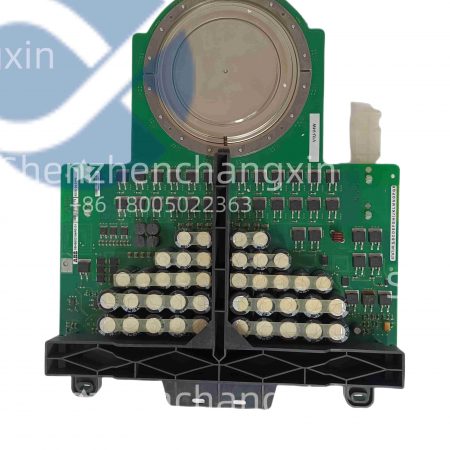

Installing the GE 1TGE120021R0610 requires mounting it onto a compatible I/O carrier base within a Mark VIe I/O pack enclosure. Field wiring connects to removable spring-clamp terminals rated for 0.2–2.5 mm² conductors, supporting daisy-chained commons for efficient panel layout. No configuration jumpers are needed—channel behavior is defined entirely in ControlST software.

Maintenance is simplified by front-facing LEDs that indicate power, network status, and per-bank input activity. In redundant systems, failed modules can be swapped during normal operation without triggering turbine alarms. GE recommends annual verification of input thresholds using a calibrated signal generator to ensure long-term accuracy.

We supply only brand-new, factory-sealed GE 1TGE120021R0610 modules with full GE documentation, original packaging, and compliance with IEC 60533 (electrical equipment on ships) and IEEE C37.90 (surge withstand). Every unit is tested for input hysteresis, isolation integrity, and network handshake before shipment. Our team provides pre-sales engineering review, post-delivery commissioning support, and lifecycle management—including obsolescence forecasting and last-time-buy coordination.

Contact us for a customized solution—whether you’re modernizing a legacy turbine control system, expanding your Mark VIe footprint, or building a strategic spares reserve for critical power generation assets.

Reviews

There are no reviews yet.