Application Scenarios:

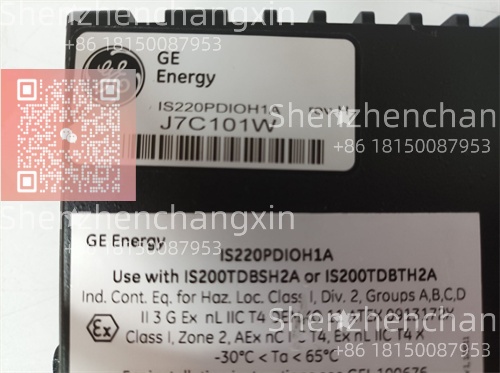

In a combined-cycle power plant, the gas turbine must operate within a precise speed range. Exceeding this range, even for milliseconds, can lead to catastrophic mechanical failure. Magnetic pickups mounted near the turbine shaft generate a small AC voltage signal whose frequency is directly proportional to shaft speed. The GE IS220PDIOH1A is the dedicated module that receives this critical signal. Installed in a Mark VIe I/O cabinet, it conditions the often noisy, low-voltage signal from the pickup. It filters out electrical noise, converts the sinusoidal wave into a clean square wave, and passes a reliable digital pulse train to the Mark VIe controller (e.g., an IS200 series CPU). The controller uses this pulse train to calculate real-time RPM. Without the accurate signal conditioning provided by the IS220PDIOH1A, electrical noise could cause false speed readings, potentially triggering an unnecessary trip or, worse, failing to detect a genuine overspeed condition. This module is therefore a frontline component in the turbine’s protection system, directly safeguarding a multi-million-dollar asset.

Technical Principles and Innovative Values:

Innovation Point 1: High-Immunity Signal Conditioning for Critical Measurements. The core innovation of the GE IS220PDIOH1A lies in its specialized analog front-end circuitry. It is not a simple digital input card. It is designed to amplify, filter, and condition the extremely weak and noisy AC signals generated by magnetic pickups in an electrically hostile environment (near high-power motors and VFDs). The module employs advanced filtering techniques to reject common-mode noise and radio-frequency interference (RFI), ensuring that only the true frequency component of the shaft rotation is passed on. This high-fidelity signal conditioning is what allows the Mark VIe controller to make reliable, split-second decisions for protection.

Innovation Point 2: Dual-Purpose Channel Configuration for Redundancy and Diagnostics. The module’s channels are often configurable and can be used in paired, redundant voting schemes for overspeed protection. For example, two independent IS220PDIOH1A channels can process signals from two separate magnetic pickups monitoring the same shaft. The control system (like a TMR controller) can perform 2-out-of-3 voting on these signals, ensuring a single sensor or channel failure does not cause a false trip nor prevent a legitimate trip. This design is fundamental to achieving high Safety Integrity Levels (SIL) for protection functions.

Innovation Point 3: Seamless Integration with Speedtronic Protection Logic. The IS220PDIOH1A is not a generic component; it is an integral, application-specific part of the Mark VIe architecture. Its performance characteristics (response time, filtering bandwidth) are precisely matched to the requirements of the turbine control application software. This co-engineering ensures that the latency between a physical speed change and the controller’s recognition of that change is minimized and deterministic, which is absolutely critical for the effectiveness of the overspeed protection system.

Application Cases and Industry Value:

Case Study: Aeroderivative Gas Turbine Generator Set Control Upgrade. A remote power generation facility using aeroderivative gas turbines for peak shaving was experiencing occasional nuisance trips traced back to unreliable speed signals. The existing speed monitoring modules were prone to noise interference. The system was upgraded with a new Mark VIe control system that included dedicated GE IS220PDIOH1A modules for both the gas generator and power turbine speed channels. The improved noise immunity of the IS220PDIOH1A immediately eliminated the spurious trips. Furthermore, the clean signals allowed the tuning of the turbine’s fuel control loops to be more aggressive, improving load response time. The plant manager reported a 99.9% reliability improvement on the speed monitoring circuits and a noticeable increase in starts-per-success metric, directly attributable to the robust signal integrity provided by the new I/O packs.

Related Product Combination Solutions:

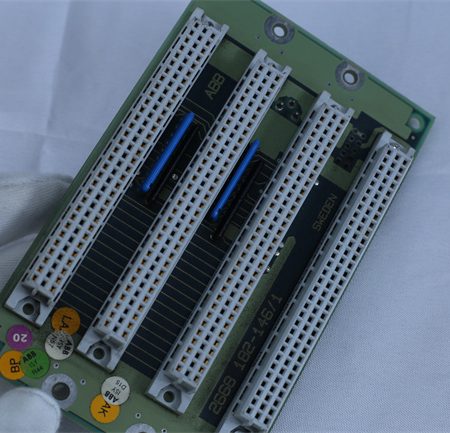

The GE IS220PDIOH1A functions within a complete speed monitoring and protection chain. Its primary partner is the Magnetic Pickup (MPU) Sensor (e.g., a Bently Nevada or equivalent probe) that generates the raw speed signal. It is mounted on a Mark VIe I/O Baseplate and connects to a Mark VIe Controller (e.g., IS215UCVEM06A). For overspeed protection, it is used in conjunction with other protective I/O like the IS220PPROH1B (Processor Proxy) module in a TMR system. The entire system is configured and monitored using GE ToolboxST application manager software. Other related I/O for a turbine control cabinet might include the IS220PAICH2A (Analog Input) for temperatures and the IS220PDIAH1A (Discrete Input) for contact closures. This ecosystem ensures a fully integrated and reliable protection solution.

Installation, Maintenance, and Full-Cycle Support:

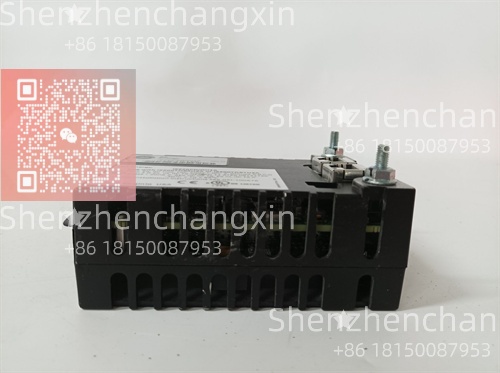

Installation of the GE IS220PDIOH1A must be performed by qualified personnel following GE Mark VIe guidelines. Critical steps include proper grounding of the module’s baseplate and the use of shielded, twisted-pair cable for the connection from the magnetic pickup to the module’s terminal block. The shield should be grounded at the cabinet end to prevent ground loops. Incorrect wiring is the most common source of noise issues. Configuration within the ToolboxST software involves setting parameters like filter frequency and input type to match the specific magnetic pickup being used.

Routine maintenance involves verifying the health of the speed monitoring loop. This can be done by checking the raw signal waveform at the module’s test points (if available) using an oscilloscope to ensure a clean sine wave of proper amplitude. The module itself has no field-serviceable parts. If diagnostics indicate a channel failure or calibration drift, the standard procedure is module replacement. Our support ensures you receive a fully compatible unit. We supply guaranteed genuine or certified refurbished GE IS220PDIOH1A (336A4940CSP23) modules. We perform functional testing prior to shipment and can assist with verifying the firmware revision compatibility with your existing Mark VIe system. Our technical team can also provide guidance on wiring best practices to ensure optimal signal integrity.

Contact us for a customized solution and to secure the right genuine GE Mark VIe components for your critical turbine protection and control system.

Reviews

There are no reviews yet.