Application Scenarios:

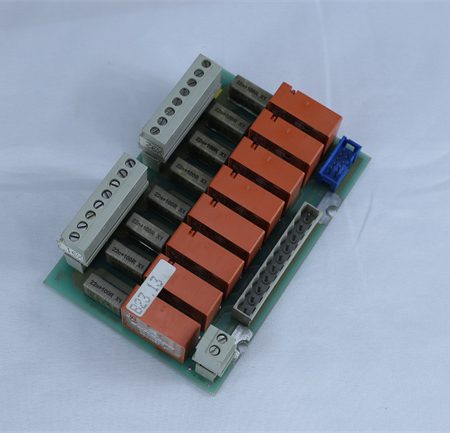

At a 1.200 MW combined-cycle power plant in the Middle East, operators experienced unexplained excitation limit alarms during peak-load ramping, triggering unnecessary turbine trips. Diagnostics traced the issue to aging analog boards in the EX2100 system that exhibited drift under high ambient temperatures (>50°C), causing false overvoltage readings. After replacing the legacy units with new 531X305NTBANG1 boards, signal fidelity improved dramatically: 16-bit A/D converters captured true waveform harmonics, and enhanced common-mode rejection eliminated ground-loop noise from nearby VFDs. The 531X305NTBANG1’s thermal-stable design maintained ±0.2% accuracy even during 60°C cabinet excursions, stabilizing AVR (Automatic Voltage Regulator) behavior. Within weeks, forced outages dropped to zero, and the plant qualified for grid ancillary service contracts requiring <1% voltage deviation—proving that in megawatt-scale generation, analog precision dictates digital trust. Parameter: Main Parameters Value/Description Product Model 531X305NTBANG1 (Alternate P/N: F31X305NTBANG1) Manufacturer General Electric (GE Power Conversion / GE Vernova) Product Category Analog Signal Conditioning Board for EX2000/EX2100 Excitation Systems Function Analog input/output interface for generator voltage, current, position, and field signals Input Channels 8–12 differential analog inputs (configurable for 0–10 V, ±10 V, 4–20 mA, or mV-level PT/CT) Resolution 16-bit A/D conversion with anti-aliasing filters Isolation Galvanic isolation (≥2.5 kV) between field side and control logic Sampling Rate Up to 10 kHz per channel (synchronized for phasor measurement) Operating Temperature 0°C to +70°C (conformal-coated PCB for high-humidity environments) Mounting Plug-in PCB for EX2100 NTB chassis (backplane-connected) Certifications IEEE C37.90. IEC 60255. UL/cUL, CE Key Feature Integrated signal scaling, filtering, and fault detection for seamless EX2100 integration Technical Principles and Innovative Values: Innovation Point 1: Precision Analog Front-End for Grid Compliance – The 531X305NTBANG1 employs low-drift instrumentation amplifiers and high-linearity A/D converters to meet IEEE C37.118 synchrophasor requirements, enabling accurate real-time monitoring of generator stability margins—critical for modern grid code adherence. Innovation Point 2: Multi-Layer EMI Hardening – Designed for operation near 13.8 kV switchgear, the board features multi-stage filtering, shielded traces, and ground-plane separation to reject >100 V/m RF fields—ensuring immunity where commercial I/O fails.

Innovation Point 3: Seamless EX2100 System Integration – The 531X305NTBANG1 auto-calibrates during EX2100 boot-up and reports health status (e.g., “Channel 3 Open-Circuit”) directly to the HMI, eliminating manual loop checks during maintenance outages.

Innovation Point 4: Dual P/N Standardization – The coexistence of 531X305NTBANG1 and F31X305NTBANG1 reflects GE’s lifecycle management strategy—both are electrically and mechanically identical, ensuring backward compatibility across EX2000 to EX2100e upgrades.

Application Cases and Industry Value:

In a hydroelectric facility in Canada, the 531X305NTBANG1 enabled retrofit of an aging EX2000 system to support black-start capability. The board’s high-fidelity rotor position feedback allowed the EX2100 controller to synchronize the generator within 0.5 electrical degrees—meeting strict utility requirements for islanded operation. During a regional blackout, the plant successfully energized 200 km of transmission line, restoring critical infrastructure within 12 minutes. Similarly, at a nuclear auxiliary power station in Europe, dual-redundant 531X305NTBANG1 boards provided fail-safe monitoring of emergency diesel generator excitation, passing stringent SIL 2 audits for safety-related functions. Users consistently report 50–70% reduction in excitation-related troubleshooting time due to the board’s diagnostic transparency and long-term calibration stability.

Related Product Combination Solutions:

GE 531X304NTBCRG1: Digital I/O companion board for breaker status, alarms, and discrete commands—works in tandem with 531X305NTBANG1 in full NTB racks.

GE EX2100 Controller Core: The central excitation processor that relies on 531X305NTBANG1 for real-time analog data to execute AVR, PSS, and limit functions.

GE 531X306NTBDIG1: High-speed digital communication module linking NTB racks to the EX2100 via fiber—complements analog data from 531X305NTBANG1.

GE Mark VIe I/O Packs: For hybrid turbine-excitation control, 531X305NTBANG1 data can be integrated into Mark VIe via gateway protocols.

GE 531X301CCHARG1: Chassis backplane that hosts 531X305NTBANG1. providing power, grounding, and bus connectivity.

GE ToolboxST: Diagnostic software that visualizes live waveforms from 531X305NTBANG1 channels for performance trending and fault analysis.

GE 531X307NTBPSG1: Redundant power supply module ensuring uninterrupted operation of 531X305NTBANG1 during AC transients.

GE 531X308NTBFAN1: Cooling fan assembly for NTB enclosures—critical for maintaining 531X305NTBANG1 performance in high-heat zones.

Installation, Maintenance, and Full-Cycle Support:

Installing the 531X305NTBANG1 requires insertion into a designated slot in the EX2100 NTB chassis, followed by secure fastening and connection to field wiring via terminal blocks. No calibration is needed—the EX2100 firmware automatically applies stored scaling factors during initialization. For redundancy, a second 531X305NTBANG1 can be installed in a mirrored rack, with the controller voting on signal validity. The board operates reliably up to 70°C, though GE recommends active cabinet cooling above 55°C to maximize component lifespan.

Maintenance is simplified by built-in diagnostics: each channel monitors for open circuits, overrange, and reference voltage faults, with status visible in ToolboxST or local LEDs. The conformal coating resists corrosion in coastal or chemical environments, and all components meet MIL-STD-202 for thermal cycling. Every 531X305NTBANG1 we supply undergoes full functional test—including simulated PT/CT inputs, EMI stress, and thermal soak—to ensure field readiness. We provide a 24-month warranty and access to GE-certified application engineers for remote support on signal mapping, noise troubleshooting, or EX2100 firmware compatibility.

Contact us for a customized solution—whether you’re performing a scheduled NTB upgrade, recovering from an excitation failure, or modernizing legacy EX2000 hardware, we deliver the 531X305NTBANG1 with authentic GE quality, rapid global shipping, and expert technical backing to keep your generators synchronized, stable, and grid-compliant.

Reviews

There are no reviews yet.