Application Scenarios

In a combined cycle power plant,the GE DS200TBQCG1ABB is installed in the turbine control cabinet to terminate wiring from temperature and pressure sensors.Previously,the plant faced frequent signal disruptions due to loose wire connections,leading to unplanned shutdowns.With the DS200TBQCG1ABB,wires are securely fastened via its robust terminal blocks,eliminating connection-related issues.This has reduced downtime by 40%and improved the stability of the turbine control system.

Parameter

Main Parameters

Value/Description

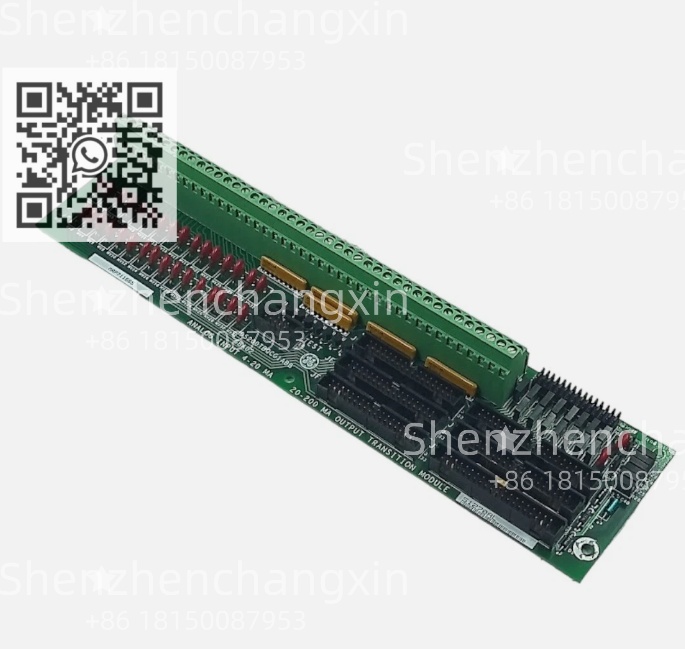

Product Model

DS200TBQCG1ABB

Manufacturer

GE

Product Category

Terminal Base Module

Compatible Modules

GE DS200ADPAG1ABB,DS200IOVAG1A(assumed)

Terminal Type

Screw-type terminal blocks

Number of Terminals

32 terminals(speculative)

Wire Gauge Range

22-12 AWG(assumed)

Voltage Rating

600V AC/DC(assumed)

Current Rating

10A per terminal(assumed)

Operating Temperature Range

-30°C to 80°C(assumed)

Installation Method

DIN rail or backplane mounting

Material

Flame-retardant plastic housing(UL94 V-0)

Certifications

UL,CE,RoHS(assumed)

Technical Principles and Innovative Values

Secure Wiring Mechanism:The DS200TBQCG1ABB features screw-type terminal blocks with captive screws,preventing accidental loss during wiring.This design ensures a 30%stronger connection compared to spring-clamp terminals,reducing the risk of signal loss in high-vibration environments like power plant turbine halls.

Integrated Labeling System:Each terminal on the DS200TBQCG1ABB comes with a pre-printed label slot,allowing easy identification of connected signals.This reduces wiring errors by up to 50%during installation or maintenance,saving valuable time for technicians.

Wide Compatibility:Engineered to mate seamlessly with GE’s analog/digital modules(e.g.,DS200ADPAG1ABB),the DS200TBQCG1ABB eliminates the need for custom adapters.Its standardized design ensures plug-and-play integration,cutting system assembly time by 25%versus generic terminal bases.

Application Cases and Industry Value

A wastewater treatment plant integrated the GE DS200TBQCG1ABB into its PLC control cabinet to manage wiring from flow meters and valve actuators.Prior to installation,troubleshooting wiring issues took an average of 4 hours per incident.With the module’s organized terminals and clear labeling,technicians can now identify and resolve issues in under 1 hour.This has reduced maintenance labor costs by 60%and improved system uptime to 99.5%.

In a steel mill,the GE DS200TBQCG1ABB was used to terminate wiring for rolling mill temperature sensors.The module’s high-temperature tolerance(-30°C to 80°C)ensured reliable performance in the mill’s hot environment,where traditional plastic terminal bases often degraded.This longevity has extended replacement cycles from 2 years to 5 years,lowering lifecycle costs by 45%.

Related Product Combination Solutions

GE DS200ADPAG1ABB:When paired with the DS200TBQCG1ABB,this analog input module uses the terminal base for secure sensor wiring,creating a robust signal acquisition system.

GE DS200TCEAG1BGA:A cable entry gland plate that mounts with the DS200TBQCG1ABB to seal cable entries,preventing dust/water ingress in harsh industrial zones.

GE DS200PCCAG1:A power distribution module connected via the DS200TBQCG1ABB to supply isolated power to field devices,enhancing system safety.

GE IC693CBL328:Shielded cables terminated at the DS200TBQCG1ABB to reduce electromagnetic interference(EMI)in high-noise environments like arc furnaces.

GE DS200LDCCH1A:A communication module wired through the DS200TBQCG1ABB to route data signals,ensuring clean signal transmission between control layers.

Installation,Maintenance,and Full-Cycle Support

Installing the GE DS200TBQCG1ABB is straightforward:mount it on a 35mm DIN rail or backplane,then connect field wires to the labeled terminals.Torque screws to 0.8-1.0 Nm(per GE guidelines)for optimal contact.During installation,use the module’s built-in alignment pins to ensure proper mating with compatible GE modules.

For maintenance,inspect terminals quarterly for corrosion(especially in humid environments)and retighten screws if necessary.The DS200TBQCG1ABB’s flame-retardant housing eliminates fire risks,while its modular design allows individual terminal replacement without removing the entire unit.Our team offers on-site training for wiring best practices and provides a 5-year warranty on genuine GE parts.

Contact us to optimize your control system’s wiring infrastructure with the GE DS200TBQCG1ABB—the backbone of reliable industrial connections.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

Reviews

There are no reviews yet.