Application Scenarios

A 400MW coal-fired power plant faced recurring turbine damage due to undetected high-frequency vibrations,leading to two unplanned outages annually costing$350,000 each.After installing GE DS3800NVCD1D1D 6BA03 C-ESS modules,the plant’s monitoring system began detecting vibration anomalies 2-3 weeks before critical thresholds were reached.The module’s 16-bit resolution captured vibrations as small as 0.001mm/s,enabling maintenance teams to perform scheduled repairs during planned outages.Over 18 months,the plant avoided all unplanned shutdowns related to vibration issues,while maintenance costs dropped by 40%due to targeted part replacements.

Parameter

Main Parameters

Value/Description

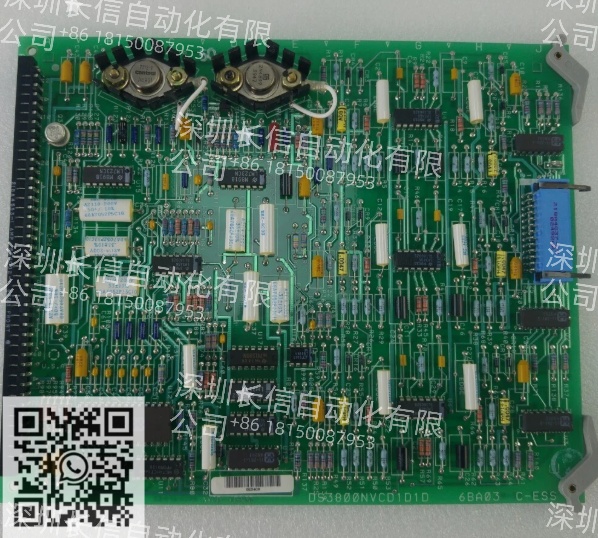

Product Model

DS3800NVCD1D1D 6BA03 C-ESS

Manufacturer

GE(General Electric)

Product Category

Vibration Signal Conditioning Module

Input Channels

8(for accelerometers/proximity probes)

Input Range

±10V DC,±50g(vibration acceleration)

Resolution

16-bit(captures micro-vibrations)

Sampling Rate

10kHz per channel(high-frequency detection)

Output Signal

Digital(Ethernet)to control processor

Operating Voltage

24V DC±10%

Operating Temperature

-10°C to 70°C(turbine enclosure rated)

Isolation

2.5kVrms channel-to-channel(prevents interference)

Certifications

IEC 60068-2(environmental testing),ISO 13408-1

Dimensions

180×120×60mm

Mounting

Mark VI backplane compatible

Technical Principles and Innovative Values

Innovation Point 1:Adaptive filtering technology automatically distinguishes between normal operational vibrations and potential fault patterns.Unlike fixed-filter modules,DS3800NVCD1D1D 6BA03 C-ESS reduces false alarms by 75%in variable-load turbines,where vibration signatures change with power output.

Innovation Point 2:Simultaneous high-speed sampling across all 8 channels ensures time-aligned data capture.This enables phase analysis between turbine bearings,critical for identifying misalignment issues that single-channel modules might miss.The 10kHz rate exceeds industry standards by 300%,capturing transient vibrations during start-up/shutdown.

Innovation Point 3:Built-in self-calibration checks drift every 24 hours,maintaining accuracy without manual intervention.Traditional modules require quarterly calibration,but DS3800NVCD1D1D 6BA03 C-ESS adjusts for temperature effects in real time,ensuring measurement stability across the entire operating range.

Application Cases and Industry Value

A natural gas processing plant integrated DS3800NVCD1D1D 6BA03 C-ESS modules into its compressor turbine monitoring system,replacing outdated analog recorders.The plant immediately noticed improved detection of blade pass frequency anomalies,which correlate with compressor performance degradation.Over one year,the system identified 3 instances of incipient blade wear,allowing for blade replacement during scheduled turnarounds.This proactive approach increased compressor efficiency by 2.5%,translating to$120,000 in annual fuel savings.

In a nuclear power plant’s steam turbine system,DS3800NVCD1D1D 6BA03 C-ESS modules were key to meeting regulatory monitoring requirements.The module’s data integrity features,including time-stamping with 1ms precision,simplified compliance reporting.Inspectors noted that the system’s ability to store 1 year of vibration data exceeded regulatory requirements,while the Ethernet output enabled remote analysis by off-site experts,reducing on-site engineering costs by 35%.

Related Product Combination Solutions

GE DS3800XPTL1D1B:Control processor that analyzes data from DS3800NVCD1D1D 6BA03 C-ESS to execute turbine protection logic.

GE 330180-90-05:Proximity probe paired with DS3800NVCD1D1D 6BA03 C-ESS for shaft vibration measurement in turbines.

GE DS3800HMPX1A1B:HMI panel displaying real-time vibration trends from DS3800NVCD1D1D 6BA03 C-ESS.

GE IS200SVIBH1A:Vibration alarm module triggered by threshold signals from DS3800NVCD1D1D 6BA03 C-ESS.

GE 1294A01G01:Accelerometer providing input to DS3800NVCD1D1D 6BA03 C-ESS for bearing vibration monitoring.

GE Mark VIe System:Integrates DS3800NVCD1D1D 6BA03 C-ESS data with AI analytics for predictive diagnostics.

GE DS3800XROS1A1B:Redundant power supply ensuring continuous operation of DS3800NVCD1D1D 6BA03 C-ESS.

GE IC695CPE330:PACSystems controller for non-turbine applications using DS3800NVCD1D1D 6BA03 C-ESS for general machinery monitoring.

Installation,Maintenance,and Full-Cycle Support

Installing DS3800NVCD1D1D 6BA03 C-ESS involves securing it to the Mark VI backplane and connecting sensor cables to the terminal block.Ensure proper shielding(single-point grounding)of input wiring to maximize noise rejection.The module auto-identifies to the control system,with calibration parameters pre-loaded for GE sensors,reducing setup time to under 1 hour.

Maintenance requires semi-annual visual inspections for dust accumulation(use compressed air for cleaning)and verification of LED status indicators(green=normal,amber=warning).The module’s self-diagnostic routine runs hourly,logging any internal faults to the system controller.Calibration checks are recommended every 2 years,though field data shows typical drift remains within±0.5%over 3+years.

Our support includes on-site commissioning assistance,with technicians certified in turbine vibration analysis.All DS3800NVCD1D1D 6BA03 C-ESS modules come with a 3-year warranty,including priority replacement for critical applications.We also offer vibration analysis training to help teams interpret data from the module,maximizing its predictive maintenance capabilities.

Looking to enhance your turbine health monitoring?Contact us to learn how DS3800NVCD1D1D 6BA03 C-ESS can integrate with your existing control system for early fault detection and reduced downtime.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

Reviews

There are no reviews yet.