Application Scenarios

In a semiconductor wafer fabrication plant, a cluster of machines for chemical vapor deposition (CVD) requires precise, synchronized real-time control. A VME-based system acts as the equipment controller, with the GE VME172PA-652SE as its computational heart. The SBC runs a real-time operating system (RTOS) that executes complex control algorithms, managing gas flow valves, temperature heaters, and robotic wafer handlers via I/O cards in the same VME chassis. Its deterministic performance ensures that time-critical control loops are executed predictably. The integrated Ethernet port allows the VME172PA-652SE to communicate with the factory’s host server, uploading production data and receiving new recipes, enabling seamless integration into a larger automated production line. This addresses the need for robust, reliable, and high-performance computing in a harsh, mission-critical industrial environment.

Parameter

VMEbus: The core industry-standard backplane architecture, providing a high-speed parallel data highway (VME64) for communication with other I/O, communication, and specialized function cards in the same chassis.

Motorola 68040: A 32-bit CISC microprocessor known for its strong performance in real-time and embedded applications of its era.

Ethernet (AMD Lance): Provides the critical network connectivity for the SBC to participate in a TCP/IP network, a key feature for modern system integration.

Technical Principles and Innovative Values

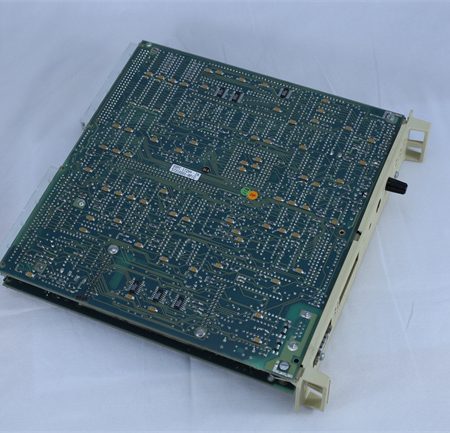

Innovation Point 1: Highly Integrated Real-Time Computing Platform

The GE VME172PA-652SE consolidated the essential components of a full computer system onto a single 6U card. It combined a powerful 32-bit CPU, RAM, non-volatile Flash, serial and parallel I/O, SCSI disk interface, and network connectivity. This high level of integration was a significant innovation, reducing the system’s physical footprint, component count, and power consumption compared to using discrete boards for each function. It provided a complete, ready-to-deploy computing engine that could be simply plugged into a VME backplane, dramatically accelerating the development and deployment of embedded control systems.

Innovation Point 2: Deterministic Performance and Robust Architecture

Designed for mission-critical applications, the board leveraged the deterministic execution characteristics of the 68040 processor and the structured interrupt handling of the VMEbus. This architecture ensured predictable response times to external events, a non-negotiable requirement for real-time control. The robust mechanical design of the 6U VME form factor, with its secure card guides and connectors, ensured reliable operation in environments with shock, vibration, and extended temperature ranges, making it suitable for industrial and military use.

Innovation Point 3: Strategic Connectivity and Expansion

The VME172PA-652SE was forward-thinking in its I/O complement. The inclusion of a SCSI-2 interface provided a high-speed pathway for connecting hard drives, which was crucial for data-intensive applications. Most importantly, integrating an Ethernet controller (the AMD Lance chip) was a key enabler, allowing these embedded systems to move beyond isolated control and become networked nodes. This facilitated remote monitoring, diagnostics, and integration with higher-level SCADA and MES systems, bridging the gap between the factory floor and the enterprise network.

Application Cases and Industry Value

Case Study: Modernization of a Rolling Mill Control System

A steel mill operated a legacy multi-board computer system for its hot rolling mill, which was becoming unreliable and unsupportable. The system required a deterministic, rugged computer to coordinate the speed and gap of rolling stands. The mill engineers chose a VME system with the GE VME172PA-652SE as the master controller.

The SBC ran a proven real-time operating system, hosting the complex rolling mill control algorithms. Its deterministic performance ensured precise timing for synchronization loops. The board’s Ethernet port connected the mill control to a new plant-wide network, allowing real-time production data (thickness, speed) to be sent to a central database. The SCSI port connected a ruggedized hard drive to log terabytes of process data for quality analysis. This upgrade, centered on the reliable VME172PA-652SE, extended the life of the mill’s control system by 15+ years. It improved product consistency by 8% through better control and provided the data needed for predictive maintenance on rolls and bearings, significantly reducing unplanned downtime.

Related Product Combination Solutions

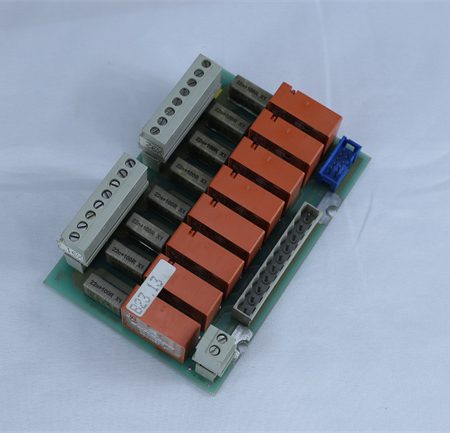

GE VMIVME-5501 (or similar): A 6U VMEbus chassis or card cage that provides the backplane, power supply, and slots for the VME172PA-652SE and other VME cards.

GE VMIVME-7700 Series: Analog and Digital I/O cards that would plug into the same VME chassis, controlled by the VME172PA-652SE to interface with sensors and actuators.

GE VMICPCI-5565 (Reflective Memory Card): A high-speed, deterministic network card that could be used in conjunction with the SBC for building real-time, shared-memory networks between multiple systems.

Wind River VxWorks or QNX Neutrino RTOS: The type of real-time operating system commonly hosted on the VME172PA-652SE for demanding control applications.

GE SBC324 (PowerPC-based SBC): A successor single board computer from GE, based on the PowerPC architecture, representing a later generation of technology for similar applications.

VMIC PCI Mezzanine Card (PMC): While the VME172 may not have a PMC site, later SBCs used these for adding functions like additional serial ports or specific networking protocols.

VME System Controller/Graphics Cards: Other cards that could reside in the same chassis, such as system controller modules or dedicated display controllers for HMI functions.

Installation, Maintenance, and Full-Cycle Support

Installation of the GE VME172PA-652SE involves installing it into a compatible 6U VME chassis. The technician must ensure the chassis is powered off, select an appropriate slot (often slot 0 or 1 if it is to act as the system controller), carefully align the board with the guide rails, and firmly press it into the J1 and optionally J2 backplane connectors until it is fully seated. External connections (Ethernet, serial cables, SCSI terminator and cable) are then made to the front panel connectors. Finally, the system is powered on, and the board’s firmware (PROM monitor) must be used to configure its VMEbus address, interrupt settings, and memory maps, and to load the operating system from its Flash memory or a SCSI disk.

Maintenance primarily involves monitoring the board’s health via software diagnostics and ensuring proper cooling in the chassis. Due to its age, common issues can include failure of the on-board battery for the real-time clock, which needs periodic replacement, or degradation of electrolytic capacitors. A full functional test involves running manufacturer-provided or custom diagnostic software to verify CPU, memory, and I/O functionality. If the board fails, the standard procedure is to replace it with a spare of identical configuration, as component-level repair is highly specialized. The system’s configuration (DIP switch settings, firmware) should be well-documented to facilitate this.

We provide comprehensive lifecycle support for the GE VME172PA-652SE and associated legacy GE systems. This includes supplying fully tested and recertified spare boards, often with refreshed batteries and capacitors. We offer expert technical assistance for system configuration, troubleshooting, and migration planning. Understanding that these systems often control critical processes, we can help source compatible peripherals, memory upgrades, and provide guidance on OS and application software compatibility. We are committed to supporting the longevity and reliability of your embedded control investments.

Contact us for detailed technical documentation, configuration support, and availability of the GE VME172PA-652SE and other legacy VME system components.

-450x375.jpg)

Reviews

There are no reviews yet.