.jpg)

Application Scenarios

In an automotive assembly line controlled by a central Siemens PLC, sensors and actuators are distributed across various stations. Running individual wires for hundreds of devices back to the main control cabinet is costly and complex. The GE 8502-BI-DP module provides an elegant solution. Installed as the first module in a VersaMax I/O rack near a welding station, it connects to the station’s local sensors (proximity switches, photo-eyes) and actuators (solenoid valves, pilot lights) via other VersaMax I/O cards in the same rack. The 8502-BI-DP then connects to the main PROFIBUS DP trunk cable. The master PLC can now read all sensor states and control all actuators at that station through a single network connection. It solves the pain points of reduced wiring, lower installation cost, modular distributed control, and easier diagnostics.

Technical Principles and Innovative Values

Innovation Point 1: Protocol Translation and I/O Mapping. The core function of the 8502-BI-DP is to act as a real-time protocol translator. It continuously maps the state of all physical I/O points in its local VersaMax rack (e.g., 16 digital inputs, 4 analog outputs) into a structured data block in its memory, formatted according to PROFIBUS DP-V1 specifications. The PROFIBUS master cyclically reads this input data block and writes an output data block. The module then updates the physical outputs accordingly. This seamless translation allows non-PROFIBUS native I/O to participate natively in a DP network.

Innovation Point 2: Modular Distributed Architecture Enabler. This module is a key enabler of a distributed, modular control architecture. Instead of a large, centralized I/O cabinet, multiple compact VersaMax racks, each with an 8502-BI-DP, can be placed close to the machines they control. This drastically reduces the amount of field wiring (sensors/actuators connect locally) and simplifies cabinet layout. Each station becomes a self-contained node on the network, making the system easier to debug, expand, and maintain.

Innovation Point 3: Configuration Flexibility and Diagnostics. The module supports the advanced PROFIBUS DP-V1 standard, which includes non-cyclic parameterization and extended diagnostics. Engineers can configure the module’s behavior (like I/O update rates) from the master. More importantly, the module provides detailed diagnostic information (module fault, power loss, communication loss) back to the master controller, which can be displayed on an HMI for quick fault localization, reducing mean-time-to-repair (MTTR).

Application Cases and Industry Value

Case 1: Packaging Machine Network Integration. A manufacturer of high-speed cartoning machines used a Siemens S7-300 PLC as the main controller but preferred the cost-effectiveness and modularity of GE VersaMax for the machine’s extensive I/O. Each machine had three main sections: feeder, carton former, and sealer, each with its own local I/O panel. An 8502-BI-DP module was installed in each panel’s VersaMax rack. A single PROFIBUS DP cable daisy-chained through the machine connected all three to the Siemens PLC. This architecture cut control wiring by over 60%, simplified machine commissioning, and allowed each section to be tested independently. The machine builder highlighted the flexibility to use best-in-class components and the clean, service-friendly layout.

Case 2: Wastewater Treatment Plant Retrofit. A plant upgraded its control system to a new central SCADA but needed to integrate several legacy filter backwash control skids. Rewiring each skid’s dozens of valves and sensors was prohibitively expensive. Instead, a VersaMax rack with an 8502-BI-DP and a mix of I/O cards was installed on each skid. The skid’s existing devices were rewired to this local rack. The 8502-BI-DP connected the skid to the plant’s new PROFIBUS DP network. This approach modernized the I/O and control logic at the skid level while providing seamless integration with the new SCADA at a fraction of the cost of a full rip-and-replace. The plant engineer valued the minimal disruption and the ability to reuse most field devices.

Related Product Combination Solutions

The GE 8502-BI-DP is the network gateway for a complete VersaMax remote I/O station:

VersaMax Power Supply (e.g., IC200PWR001): Provides power to the rack and all modules.

VersaMax I/O Modules: The actual input and output cards that connect to field devices. Examples:

Digital Input: IC200MDL740 (16-point 24VDC In)

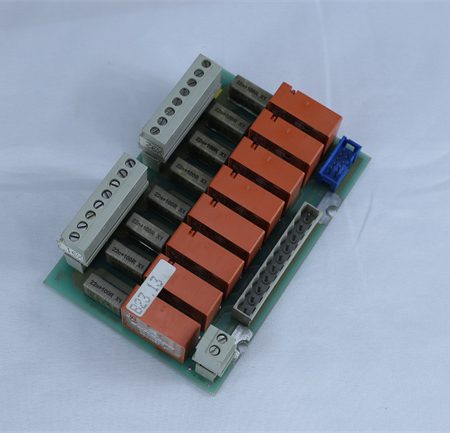

Digital Output: IC200MDL940 (16-point Relay Out)

Analog Input: IC200ALG630 (4-channel Analog In)

VersaMax Rack/Base (e.g., IC200CHSxxx): The chassis that holds the modules and provides the backplane bus.

PROFIBUS DP Master: A PLC or controller (e.g., Siemens S7-1500. Emerson/GE RX3i with a PROFIBUS master module) that manages the network.

PROFIBUS DP Network Components: Cable, connectors, and terminators for the physical network.

Configuration Software (Emerson Machine Edition or equivalent): Used to configure the I/O mapping and parameters of the VersaMax station, which is then reflected in the master’s configuration (e.g., Siemens Step 7).

Installation, Maintenance, and Full-Cycle Support

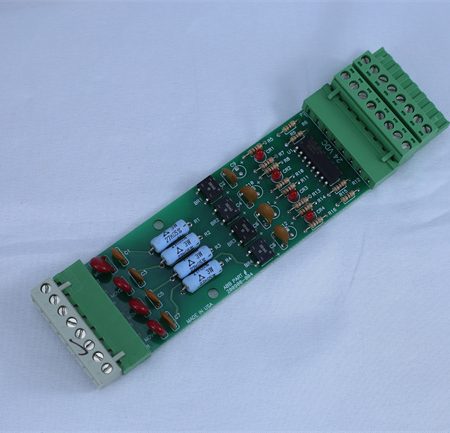

Installation involves securing the VersaMax rack, inserting the 8502-BI-DP into the first slot (usually slot 0), and populating the remaining slots with the required I/O modules. The PROFIBUS address is set using the rotary switches. The PROFIBUS DP cable is connected to the module’s 9-pin D-sub port. Configuration is done in two places: the I/O configuration in the VersaMax software (if used) and, most critically, the device configuration (GSD file) and I/O mapping in the master PLC’s programming software.

Routine maintenance involves monitoring the module’s status LEDs (PWR, OK, NET, I/O). The master PLC’s diagnostic screens provide detailed network and slave status. The module itself requires no maintenance. If it fails, it can be replaced by powering down the rack, swapping the module, setting the same PROFIBUS address, and re-establishing power. The configuration is stored in the master, so the new module will be recognized automatically.

We provide full support for GE/Emerson VersaMax systems. We can supply the genuine 8502-BI-DP module, assist with identifying the correct GSD file for your master PLC, and help with basic configuration guidance. Our expertise ensures you can successfully integrate this versatile communication module into your automation network.

Integrate VersaMax I/O into your PROFIBUS DP network efficiently. Contact us for the GE 8502-BI-DP module and integration support.

.jpg)

.jpg)

Reviews

There are no reviews yet.