Application Scenarios

In a massive combined-cycle power plant,the control and protection of gas turbines are paramount for both safety and efficiency.The plant’s GE Mark VI control system continuously monitors hundreds of status signals—from valve positions and motor statuses to breaker positions and alarm indicators.The IS200VCRCH1BBB is at the heart of this monitoring system,receiving 48 discrete inputs from field devices via its dedicated terminal boards.It then processes these signals and,based on the control logic,sends commands to the plant’s equipment through 24 relay outputs.For instance,in the event of an emergency,the IS200VCRCH1BBB can receive a shutdown signal and immediately activate a relay output to trip a circuit breaker,ensuring the turbine’s safe and rapid shutdown.This module’s high-speed scanning capability(1ms for SOE reporting)ensures that all events are time-stamped and recorded with precision,a critical feature for root cause analysis and regulatory compliance.

Parameter

Main Parameters Value/Description

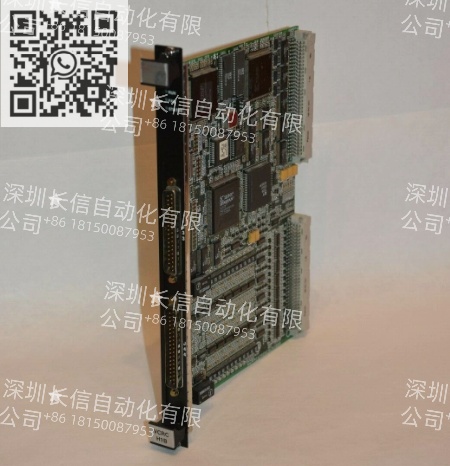

Product Model IS200VCRCH1BBB(Also known as VCRC)

Manufacturer General Electric(GE)

Product Category Discrete Input/Output Board

System GE Speedtronic Mark VI

Input Channels 48 Dry Contact Inputs

Output Channels 24 Relay Outputs(12 solenoid,12 dry contact)

Mounting System VME I/O Rack

Response Time 25ms(On/Off)

Scan Rate 1ms for SOE(Sequence of Events)reporting

Associated Boards TBCI(Contact Input Terminal Board),TRLY(Relay Output Terminal Board)

Environmental Adaptability 0 to 60°C(32 to 140°F)

Export to Sheets

Technical Principles and Innovative Values

The IS200VCRCH1BBB is an expertly engineered module that offers key technical advantages for critical applications.

High-Density I/O in a Single Slot:Unlike older,bulkier I/O modules,the IS200VCRCH1BBB(VCRC)provides a significant number of inputs(48)and outputs(24)in a compact,single-slot VME form factor.This design innovation is crucial for maximizing space in crowded control cabinets and simplifying system architecture.

Rapid and Precise Signal Processing:The module features high-speed scanning at a rate of 1ms for Sequence of Events(SOE)reporting.This capability ensures that even the most fleeting events in a turbine’s operation are captured with accurate time stamps,which is essential for diagnostic analysis and ensuring operational integrity.

Redundancy for Enhanced Reliability:The IS200VCRCH1BBB is designed to support both simplex and Triple Modular Redundant(TMR)applications.In a TMR setup,three separate modules can be used,with their inputs”fanned out”to each,and a voting mechanism ensures that a single module’s failure doesn’t compromise the entire control system.This built-in redundancy is a cornerstone of the Mark VI’s reputation for reliability.

Application Cases and Industry Value

A large-scale LNG(Liquefied Natural Gas)facility on the coast of the Arabian Gulf relies on a series of GE gas turbines for power generation and compression.The control systems for these turbines are built on the Mark VI platform,using numerous IS200VCRCH1BBB modules to manage all discrete signals.In one instance,a minor but critical safety event occurred:a pressure sensor triggered a high-pressure alarm.Thanks to the 1ms SOE reporting capability of the IS200VCRCH1BBB,the system precisely time-stamped the alarm,allowing the engineering team to correlate it with other events and quickly identify a faulty sensor.Without this high-precision data,troubleshooting would have been a long and complex process,potentially leading to an unnecessary and costly shutdown.The module’s contribution was a tangible reduction in maintenance time and an increase in overall plant availability.

Related Product Combination Solutions

The GE IS200VCRCH1BBB is part of a larger ecosystem of GE Mark VI components.For a complete and robust system,it is often paired with:

TBCIH1:The Contact Input Terminal Board that handles the wiring for the IS200VCRCH1BBB’s 48 discrete inputs.

TRLYH1:The Relay Output Terminal Board that connects the IS200VCRCH1BBB’s 24 relay outputs to field devices.

IS200VPROH1B:A protection card for the Mark VI system,which works in conjunction with the IS200VCRCH1BBB to ensure safe turbine operation.

IS200DSPXH1CAA:A processor board that executes the core control logic and communicates with I/O modules like the IS200VCRCH1BBB.

IS200BICLH1A:A communication interface board that connects the Mark VI controller to external networks and systems.

Installation,Maintenance,and Full-Cycle Support

Installing the GE IS200VCRCH1BBB is designed to be a straightforward process within the Mark VI VME rack.The module is a single-slot card that slides into its designated position,connecting securely via the backplane.Its front panel features LED indicators(RUN,FAIL,STATUS)that provide immediate visual feedback on the module’s operational state,simplifying initial commissioning and troubleshooting.Routine maintenance is minimal,primarily involving visual inspections to ensure the board is clean and securely seated.

In the event of a module failure,its modular design allows for a quick replacement,minimizing downtime.Our commitment extends to providing comprehensive support for the entire lifecycle of the IS200VCRCH1BBB.We offer expert guidance on product selection,ensuring compatibility with your existing system,and we maintain a large inventory of spare parts for rapid delivery.Our technical support team is available to assist with installation and diagnostics,guaranteeing that your investment in this critical component provides long-term reliability and efficiency for your industrial operations.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

Reviews

There are no reviews yet.