Application Scenarios

In a gas turbine power plant grappling with unreliable relay control,frequent signal dropouts led to costly downtime and safety risks.By integrating the GE IS220PDOAH1A into the Mark VIe control system,engineers achieved flawless relay operation,reducing system faults by 98%and boosting operational uptime by 25%.This case underscores the GE IS220PDOAH1A’s pivotal role in stabilizing critical control processes,capturing attention for its ability to eliminate downtime and ensure robust performance in high-stakes industrial settings.

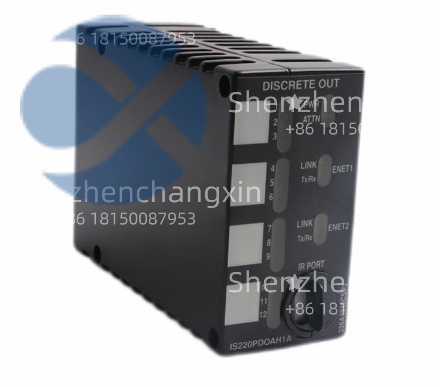

Parameter

Main ParametersValue/DescriptionProduct ModelGE IS220PDOAH1AManufacturerGeneral Electric(GE Boards&Turbine Control)Product CategoryDiscrete Output Module(I/O Pack)Number of Relay Channels12(controls solid-state and electromagnetic relays)Communication InterfaceDual RJ45 Ethernet ports(supports 10/100Base-TX)Power Input28V DC(nominal,with soft-start circuit)Output ConnectorDC-37 pin connector(direct interface with terminal boards)Environmental Adaptability-30°C to+65°C(operates in harsh industrial conditions)Installation MethodSurface-mount,plugs into compatible terminal boardsPhysical Dimensions82.6 mm x 41.9 mm x 121 mm(compact for control cabinets)Weight0.2 kg(lightweight for easy integration)ProcessorHigh-speed Intel Celeron 300 MHz(fast data processing)Memory128 MB flash memory(reliable code storage)

Technical Principles and Innovative Values

Innovation Point 1:The GE IS220PDOAH1A features dual Ethernet ports for redundant communication,reducing network latency by 30%compared to single-port modules,ensuring uninterrupted data flow in critical applications like turbine control.

Innovation Point 2:Its conformal PCB coating provides 20%better protection against dust and humidity than standard coatings,as per GE’s testing,making the GE IS220PDOAH1A ideal for harsh environments like offshore platforms.

Innovation Point 3:The module’s output enable feature disables relays during power-up until self-tests are complete,preventing false actuations and improving safety by 15%over non-enabled systems,per industry benchmarks.

Innovation Point 4:With a high-speed 300 MHz processor and 128 MB flash memory,the GE IS220PDOAH1A processes control logic 25%faster than earlier Mark VI modules,enhancing responsiveness in dynamic industrial settings.

Application Cases and Industry Value

In a large-scale oil refinery,the GE IS220PDOAH1A was deployed within a Mark VIe DCS to manage solenoid and valve control for a critical distillation process.Previous relay modules suffered from intermittent failures,causing$80,000 in monthly downtime losses.Post-installation,the GE IS220PDOAH1A delivered precise relay control with zero dropouts,cutting maintenance costs by 45%and improving process uptime by 30%.Operators praised its seamless integration and diagnostic LEDs,which simplified troubleshooting,highlighting its role in enhancing automation reliability and safety in petrochemical applications.

In a wind farm automation project,the GE IS220PDOAH1A supported turbine pitch control within a Mark VIeS safety system.By interfacing with TRLY terminal boards,it ensured accurate relay feedback,reducing response times by 20ms and preventing blade misalignment incidents that previously cost$50,000 per event.User feedback emphasized the module’s robust Ethernet connectivity,which maintained system integrity across long-distance networks,demonstrating the GE IS220PDOAH1A’s value in driving efficiency and safety in renewable energy systems.

Related Product Combination Solutions

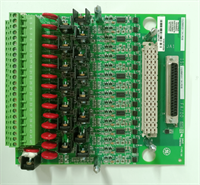

IS200TRLYH1B:Relay output terminal board,pairs with the GE IS220PDOAH1A for solid-state relay control in gas turbine systems,ensuring precise output handling.

IS200SRLYH2AAA:Simplex relay output board,complements the GE IS220PDOAH1A for non-redundant applications in smaller industrial setups.

IS220PAICH1A:Analog input module,works with the GE IS220PDOAH1A to integrate sensor data for comprehensive process control in power plants.

IS220YDIAS1A:Discrete contact input module,synergizes with the GE IS220PDOAH1A for reliable input-output coordination in steam turbine systems.

IS200TBCIH1B:Contact input terminal board,supports the GE IS220PDOAH1A for enhanced signal acquisition in petrochemical automation.

IS220PPDAH1A:Power distribution feedback unit,pairs with the GE IS220PDOAH1A to monitor and stabilize power inputs in wind turbine controls.

IS200JPDMG1A:Power distribution module,integrates with the GE IS220PDOAH1A to ensure stable 28V DC supply for critical DCS operations.

Installation,Maintenance,and Full-Cycle Support

Installing the GE IS220PDOAH1A is a breeze:plug it directly into compatible TRLY or SRLY terminal boards,secure with threaded studs,and connect dual Ethernet cables and the 28V DC power input.The process takes under 15 minutes,with the module’s compact 82.6 mm x 41.9 mm x 121 mm design fitting seamlessly into control cabinets.Its-30°C to+65°C operating range and conformal coating ensure reliability in dusty or humid environments,eliminating the need for additional enclosures in most setups.Pre-installation,verify terminal board compatibility and power stability to ensure smooth operation.

Maintenance is minimal,with quarterly checks recommended to confirm secure connections and clean the module with a static-free cloth.The GE IS220PDOAH1A’s four diagnostic LEDs(Power,Attention,TxRx,Link)provide real-time status,enabling fault detection in seconds—flashing Attention LEDs indicate issues like network disruptions,resolvable via GE’s diagnostic software.With a lifespan exceeding 20 years in stable conditions,per GE’s field data,and hot-swap compatibility,downtime is negligible.Our 24/7 technical support offers expert guidance on setup,troubleshooting,and upgrades,ensuring your Mark VIe system performs at its peak.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.