Application Scenarios

In a large semiconductor fabrication plant, even a momentary voltage sag or harmonic distortion can disrupt sensitive production equipment, leading to costly scrap and downtime. The GE PQM-T20-C-A is installed at the main incoming service and critical distribution panels. It continuously monitors for power quality events like sags, swells, and transients. When a voltage sag caused by a fault on the utility grid occurs, the meter captures the event’s waveform, magnitude, and duration. Engineers use this data to correlate the power event with the simultaneous failure of several robots, providing irrefutable evidence for a utility claim and enabling the implementation of mitigation strategies like UPS systems, directly addressing the pain points of unexplained process interruptions and financial loss.

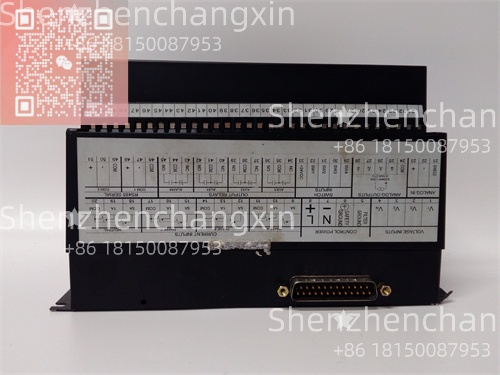

Parameter

Technical Principles and Innovative Values

The GE PQM-T20-C-A is an intelligent sensor and analyzer that transforms raw voltage and current waveforms into actionable insights for power system health and efficiency.

Innovation Point 1: High-Fidelity, Multi-Resolution Waveform Capture. Beyond simple RMS value logging, the meter captures high-resolution waveform data during steady-state and transient events. It can store detailed cycles of a voltage sag, a switching transient, or an inrush current. This capability is crucial for root cause analysis, allowing engineers to “see” the disturbance, understand its characteristics, and differentiate between utility-side events and internal plant equipment issues.

Innovation Point 2: Advanced Power Quality Analysis to Industry Standards. The device performs detailed analysis according to stringent standards like IEC 61000-4-30 Class A. It accurately measures parameters like voltage unbalance, flicker (Pst/Plt), and individual harmonics. This standardized, high-accuracy data is defensible for utility negotiations, compliance reporting, and benchmarking, moving power management from anecdotal evidence to data-driven decision-making.

Innovation Point 3: Flexible Communication and Protocol Support. The PQM-T20-C-A acts as a data node in a modern connected system. With support for key industrial protocols (Modbus, DNP3) and the utility-standard IEC 61850. it can seamlessly feed data into a wide range of systems—from a plant’s SCADA or Building Management System (BMS) to a utility’s distribution management system—enabling centralized monitoring, alarming, and historical analysis.

Innovation Point 4: Integrated Energy and Demand Profiling. The device provides not just instantaneous readings but also logs energy (kWh) and demand (kW) over configurable intervals (e.g., 15-minute). This allows for detailed load profiling, peak demand analysis, and utility bill verification. It helps identify wasteful consumption patterns, validate energy-saving projects, and manage demand charges, which are often a significant portion of an industrial electricity bill.

Application Cases and Industry Value

Case 1: Solving Chronic Equipment Trips in a Plastic Injection Molding Plant

A plastics manufacturer experienced random trips of variable frequency drives (VFDs) controlling hydraulic pumps, causing inconsistent production cycles. Suspecting “dirty power,” they installed GE PQM-T20-C-A meters at the main service and at the VFD panels. The meters revealed recurring, sub-cycle voltage notches caused by a large DC drive in an adjacent facility. The detailed waveform capture from the PQM-T20-C-A provided conclusive evidence. The plant installed a dedicated line reactor and tuned the VFDs’ sensitivity based on the meter’s data. The maintenance manager reported a complete elimination of nuisance trips, increasing Overall Equipment Effectiveness (OEE) by 15% and saving thousands in lost production and component replacements.

Case 2: Reducing Energy Costs and Demand Charges for a Commercial Campus

A university campus with a central chiller plant and dozens of buildings faced steadily rising electricity bills and high peak demand charges. GE PQM-T20-C-A meters were installed at the utility meter point and major feeder circuits. The data revealed that simultaneous morning startup of large HVAC units was creating a significant “demand ratchet.” Using the meters’ load profiling data, facilities management implemented a staggered start sequence for the chillers and optimized the building automation system’s setpoints. The finance director confirmed a 12% reduction in peak demand and an 8% overall reduction in the monthly electricity bill, resulting in annual savings of over $120.000. with a payback period for the meters of under six months.

Related Product Combination Solutions

The GE PQM-T20-C-A is the central intelligence unit in a power monitoring system. It is deployed as part of a complete measurement and communication chain:

Voltage Transformers (VTs/PTs) and Current Transformers (CTs): Instrument transformers that step down high voltage and current to safe, measurable levels compatible with the meter’s inputs. Selection of the correct ratio and accuracy class (e.g., 0.5 class) is critical.

Wiring, Test Switches, and Safety Fuses: The physical connection components, including wiring from CTs/PTs, test blocks for safe isolation, and fusing for voltage circuits.

.

Communication Network Infrastructure: Ethernet switches, serial-to-Ethernet converters, and cabling to connect the PQM-T20-C-A to the plant network for SCADA/BMS integration.

Power Monitoring Software (e.g., GE Power Monitoring Expert, Schneider PowerSCADA, or other platforms): A central software platform that aggregates data from multiple PQM-T20-C-A meters, provides advanced visualization, analytics, reporting, and alarming. This unlocks the full value of the meter’s data.

SCADA/HMI or BMS System: The overarching control or management system that may use Modbus or IEC 61850 to bring the meter’s data points (kWh, kW, V, etc.) into its graphics and alarm database for operator visibility.

Portable Power Quality Analyzer (e.g., GE Power-Vu or Fluke 1750): A portable device used for temporary, detailed troubleshooting, which can be cross-referenced with the permanent PQM-T20-C-A data for correlation.

Protective Relays and Circuit Breakers: The PQM-T20-C-A provides monitoring and analysis, while protective devices (like GE Multilin relays) take automatic action to isolate faults. The data from the meter is invaluable for coordinating and setting these protection devices.

Installation, Maintenance, and Full-Cycle Support

Installation involves several critical steps: First, ensuring the power is safely isolated. Second, mounting the meter in a panel. Third, correctly connecting the voltage and current inputs from the instrument transformers, paying strict attention to phase rotation and polarity. Incorrect wiring will yield invalid data. Finally, connecting the communication cable (Ethernet or RS-485) and configuring the meter’s IP address, protocol settings, and CT/VT ratios via the front panel or software. Commissioning typically involves verifying readings against a known reference.

Routine maintenance is minimal. The primary tasks involve periodic verification of data accuracy against a clamp-on meter or portable standard, checking communication connectivity, and ensuring the device’s clock is synchronized (often via network time protocol). Data should be regularly backed up from the onboard memory or retrieved from the central software. The meter is designed for long-term, stable operation. In the event of a fault, the modular unit can be replaced, and the configuration can be restored from a backup. We provide comprehensive support for the GE PQM-T20-C-A, from initial system design and device configuration to integration with your monitoring software. Our services include supply of the hardware, technical guidance, and ongoing support to help you turn electrical data into operational and financial benefits.

Contact us for expert advice on implementing a power quality and energy monitoring solution with the GE PQM-T20-C-A meter to enhance the reliability, efficiency, and intelligence of your electrical system.

Reviews

There are no reviews yet.